Revolutionizing Product Reliability The Power of Vibration Simulation in Eurolabs Laboratory Services

In todays fast-paced and competitive business landscape, ensuring product reliability is crucial for companies across various industries. A single faulty component or malfunctioning device can lead to costly recalls, damage to reputation, and significant financial losses. To mitigate such risks, businesses are increasingly turning to advanced laboratory services that simulate real-world conditions, allowing them to test and validate their products with unprecedented accuracy.

One such game-changing service is Vibration Simulation, offered by Eurolab a leading provider of cutting-edge laboratory solutions. In this article, well delve into the world of Vibration Simulation, exploring its significance, advantages, and benefits for businesses. By the end of this comprehensive guide, youll understand why Vibration Simulation has become an essential tool in the pursuit of product reliability.

What is Vibration Simulation?

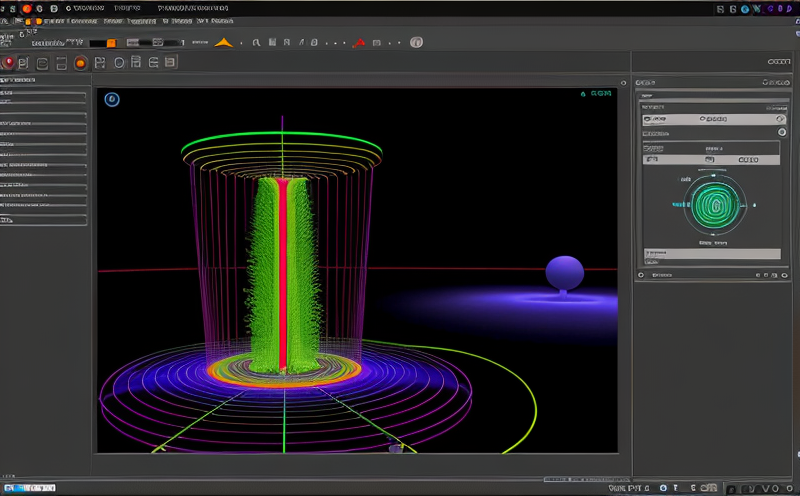

Vibration Simulation is a laboratory service that replicates the dynamic forces and vibrations encountered by products during transportation, usage, or installation. This advanced testing method allows companies to evaluate their products performance under various scenarios, including shock, vibration, and impact loading. By simulating real-world conditions in a controlled environment, Eurolabs Vibration Simulation enables businesses to identify potential issues before they become major problems.

Why is Vibration Simulation essential for businesses?

The importance of Vibration Simulation cannot be overstated. Here are just a few compelling reasons why this service has become an indispensable tool for companies

Reduced Risk By simulating real-world conditions, Vibration Simulation helps identify potential product failures, reducing the risk of costly recalls and reputational damage.

Increased Efficiency This laboratory service streamlines the testing process, allowing businesses to accelerate their development timelines and get products to market faster.

Improved Product Quality Vibration Simulation enables companies to validate their products performance under various conditions, ensuring they meet or exceed customer expectations.

Cost Savings By identifying potential issues early on, businesses can avoid costly redesigns, rework, and repairs.

Key Benefits of Vibration Simulation

Eurolabs Vibration Simulation offers numerous benefits for businesses. Here are some of the most significant advantages

Accurate Results Our state-of-the-art equipment and expert technicians ensure precise results that reflect real-world conditions.

Customized Testing We tailor our services to meet your specific needs, providing a comprehensive understanding of your products performance under various scenarios.

Time-Saving Vibration Simulation accelerates the testing process, allowing you to quickly identify potential issues and make data-driven decisions.

Cost-Effective By simulating real-world conditions, we help you avoid costly redesigns, rework, and repairs.

Compliance with Industry Standards Our services ensure compliance with industry-specific standards and regulations, reducing the risk of non-compliance penalties.

How Does Vibration Simulation Work?

The process of Vibration Simulation involves several key steps

Product Preparation Your product is carefully prepared for testing by our expert technicians.

Vibration Testing Our state-of-the-art equipment simulates real-world conditions, replicating the dynamic forces and vibrations your product will encounter.

Data Analysis We collect and analyze data from the vibration test, providing a comprehensive understanding of your products performance under various scenarios.

Reporting and Recommendations Our expert technicians compile a detailed report outlining the results of the Vibration Simulation test, including recommendations for improvement.

Frequently Asked Questions (FAQs)

Weve compiled some of the most common questions about Vibration Simulation to help you better understand this laboratory service

Q What types of products can be tested using Vibration Simulation?

A Our Vibration Simulation services cater to a wide range of industries and product types, including but not limited to automotive, aerospace, consumer electronics, and heavy machinery.

Q How long does the testing process typically take?

A The duration of the testing process varies depending on the specific requirements of your project. Our expert technicians will work with you to determine the optimal testing schedule.

Q What kind of data can I expect from the Vibration Simulation test?

A We provide a comprehensive report detailing the results of the vibration test, including data on product performance, durability, and reliability.

Conclusion

In conclusion, Eurolabs Vibration Simulation is an indispensable tool for businesses seeking to ensure product reliability and efficiency. By simulating real-world conditions in a controlled environment, this laboratory service helps companies identify potential issues before they become major problems. With its numerous benefits, including reduced risk, increased efficiency, improved product quality, and cost savings, Vibration Simulation has become an essential component of any product development process.

Dont let faulty components or malfunctioning devices put your business at risk. Contact Eurolab today to learn more about our comprehensive laboratory services, including Vibration Simulation. Together, we can help you develop products that meet the highest standards of quality and reliability.