Waterproof Seal Durability Testing for Battery Compartments

The Ultimate Assurance for Waterproof Battery Compartments Eurolabs Expertise in Durability Testing

In todays fast-paced world of technology and innovation, the development of electronic devices is becoming increasingly complex. With the rise of portable electronics, wearable gadgets, and electric vehicles, manufacturers are under immense pressure to ensure that their products can withstand various environmental conditions without compromising performance or safety. One crucial aspect of product design is waterproofing, particularly when it comes to battery compartments. A single failure in this area can lead to catastrophic consequences, including damage to the device itself, harm to users, and costly repairs.

This is where Waterproof Seal Durability Testing for Battery Compartments comes into play a specialized laboratory service offered by Eurolab that empowers businesses to guarantee the reliability of their products. By subjecting battery compartments to rigorous testing protocols, manufacturers can validate their designs, ensure compliance with industry standards, and ultimately reduce the risk of costly recalls or reputation damage.

What is Waterproof Seal Durability Testing for Battery Compartments?

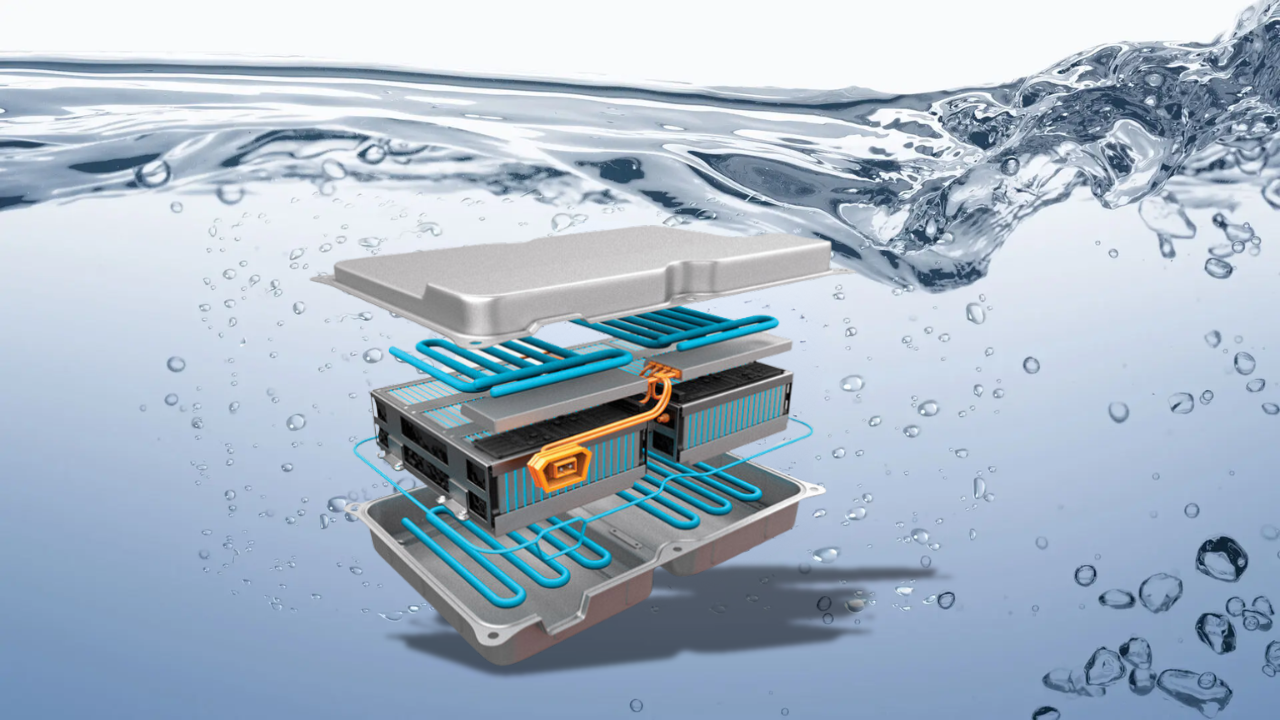

Waterproof Seal Durability Testing for Battery Compartments involves simulating real-world environmental conditions to assess the effectiveness of a products sealing mechanism. This laboratory service evaluates the seals ability to withstand exposure to water, humidity, and other corrosive substances, ensuring that it remains intact even under prolonged stress.

At Eurolab, our team of experts employs state-of-the-art equipment and techniques to simulate various environmental scenarios, including

High-temperature and high-humidity conditions

Exposure to saltwater and other aggressive chemicals

Immersion in water at different depths and pressures

By subjecting battery compartments to these simulated environments, we can determine the seals durability, leak rate, and overall performance.

Why is Waterproof Seal Durability Testing for Battery Compartments Essential?

The advantages of using Waterproof Seal Durability Testing for Battery Compartments are multifaceted

Risk Mitigation By identifying potential weaknesses in a products design, manufacturers can address them before mass production begins, reducing the likelihood of costly recalls or reputation damage.

Compliance Assurance Eurolabs testing protocols ensure that products meet industry standards, such as those set by IP67, IP68, and UL 94 (Underwriters Laboratories) regulations.

Increased Customer Trust When manufacturers can demonstrate the reliability of their products sealing mechanisms, they build trust with customers, who are more likely to purchase and recommend their products.

Cost Savings By validating product designs through rigorous testing, businesses can avoid costly redesigns or retooling efforts.

Here are some key benefits of using Waterproof Seal Durability Testing for Battery Compartments

Advantages

Improved Product Reliability Eurolabs testing protocols help manufacturers identify and address design flaws, ensuring that products perform consistently in real-world environments.

Enhanced Safety Features By evaluating a products sealing mechanism under various environmental conditions, we can identify potential safety risks, allowing manufacturers to implement corrective actions before production begins.

Reduced Warranty Claims When products are designed with reliability in mind, customers are less likely to file warranty claims due to water damage or other related issues.

Competitive Advantage Manufacturers who prioritize waterproofing and sealing mechanisms can differentiate themselves from competitors, attracting customers seeking reliable and durable products.

QA Your Questions Answered

Q1 What types of products require Waterproof Seal Durability Testing for Battery Compartments?

A1 Any product with a battery compartment that requires protection against water or humidity, such as electric vehicles, drones, wearables, medical devices, and portable electronics.

Q2 How does Eurolabs testing protocol simulate real-world environmental conditions?

A2 Our team employs state-of-the-art equipment to replicate various environmental scenarios, including high-temperature and high-humidity conditions, saltwater exposure, and immersion in water at different depths and pressures.

Q3 Can I customize the testing protocol for my specific product needs?

A3 Yes! Eurolab offers customized testing protocols tailored to your products unique requirements. Our experts will work with you to develop a comprehensive testing plan that addresses your specific concerns.

Q4 What is the typical turnaround time for Waterproof Seal Durability Testing for Battery Compartments?

A4 Turnaround times vary depending on the complexity of the testing protocol and the number of samples submitted. However, we typically deliver results within 2-6 weeks.

Conclusion

In todays competitive market, manufacturers must prioritize product reliability and safety above all else. Waterproof Seal Durability Testing for Battery Compartments is a critical laboratory service that empowers businesses to validate their designs, ensure compliance with industry standards, and build trust with customers. By partnering with Eurolab, you can rest assured that your products are designed to withstand the rigors of real-world environments.

Dont risk reputation damage or costly recalls choose Eurolabs Waterproof Seal Durability Testing for Battery Compartments today!