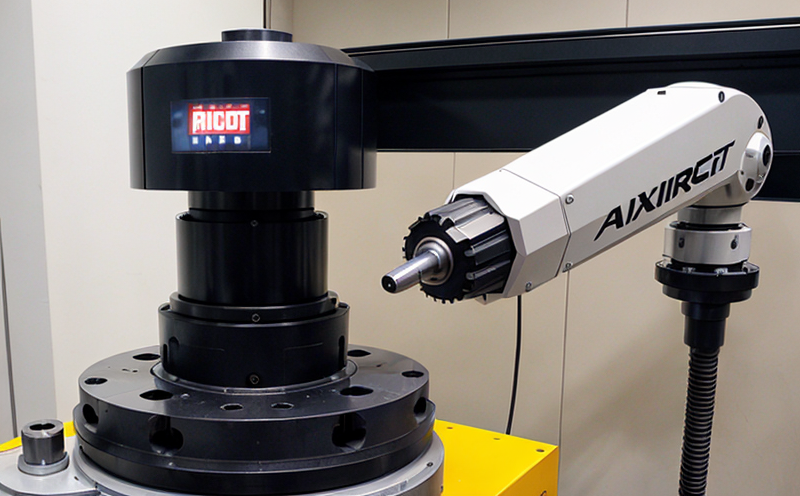

Accuracy validation for multi-axis robots used in inspection tasks

The Crucial Role of Accuracy Validation for Multi-Axis Robots in Inspection Tasks Enhancing Business Efficiency and Reliability

In todays fast-paced industrial landscape, the need for precise inspection and testing has never been more pressing. As companies strive to maintain high-quality products and services, the use of multi-axis robots in inspection tasks has become increasingly prevalent. However, with great complexity comes great responsibility ensuring that these robots meet the required accuracy standards is a crucial aspect of maintaining business efficiency and reliability.

What is Accuracy Validation for Multi-Axis Robots used in Inspection Tasks?

Accuracy validation for multi-axis robots refers to the process of verifying the precision and reliability of robotic systems designed to perform inspection tasks. This laboratory service involves subjecting the robots movement, positioning, and calibration data to a rigorous testing protocol, ensuring that it meets or exceeds industry standards.

Why is Accuracy Validation for Multi-Axis Robots used in Inspection Tasks Essential?

Incorporating accuracy validation into your quality control measures can have far-reaching benefits for businesses. Some of these advantages include

Advantages of Using Accuracy Validation for Multi-Axis Robots used in Inspection Tasks

Improved Product Quality By verifying the accuracy of multi-axis robots, companies can ensure that products meet or exceed industry standards, leading to increased customer satisfaction and loyalty.

Reduced Downtime When inspection tasks are executed with precision, equipment is less likely to experience mechanical failure, resulting in reduced downtime and lower maintenance costs.

Increased Efficiency Accuracy validation allows for the optimization of robotic systems, enabling companies to streamline production processes and increase overall productivity.

Enhanced Safety By ensuring that robots meet accuracy standards, companies can minimize the risk of human error, reducing the likelihood of accidents and improving workplace safety.

Compliance with Industry Standards Accuracy validation enables businesses to demonstrate compliance with industry regulations, maintaining a competitive edge in the market.

Long-Term Cost Savings Investing in accuracy validation can lead to significant long-term cost savings by minimizing equipment failure, maintenance needs, and rework requirements.

The Eurolab Advantage Expertise and Experience

At Eurolab, our team of skilled technicians and engineers is dedicated to providing comprehensive accuracy validation services for multi-axis robots used in inspection tasks. Our laboratory boasts state-of-the-art equipment and a commitment to delivering exceptional results.

QA Section Your Questions Answered

Frequently Asked Questions about Accuracy Validation for Multi-Axis Robots used in Inspection Tasks

What is the purpose of accuracy validation for multi-axis robots?

The primary objective of accuracy validation is to verify that robotic systems meet or exceed industry standards, ensuring precision and reliability in inspection tasks.

How does Eurolab conduct accuracy validation tests?

Our laboratory follows a rigorous testing protocol, subjecting the robots movement, positioning, and calibration data to a series of precise measurements and analyses.

What are the benefits of conducting accuracy validation on a regular basis?

Regular accuracy validation can help businesses maintain high product quality, reduce downtime, increase efficiency, enhance safety, and comply with industry standards.

Can Eurolab assist with recalibration or realignment if necessary?

Yes, our team is experienced in recalibrating or realigning robotic systems to ensure optimal performance.

What industries can benefit from accuracy validation for multi-axis robots used in inspection tasks?

Any industry utilizing robotic inspection systems, such as aerospace, automotive, medical device manufacturing, and pharmaceuticals, can benefit from Eurolabs accuracy validation services.

Conclusion

In conclusion, accuracy validation for multi-axis robots used in inspection tasks is an indispensable aspect of maintaining business efficiency and reliability. By partnering with Eurolab, companies can ensure that their robotic systems meet or exceed industry standards, leading to improved product quality, reduced downtime, increased efficiency, enhanced safety, compliance with industry regulations, and long-term cost savings.

Take the First Step Towards Enhanced Quality and Reliability

Invest in the accuracy validation services offered by Eurolab today. Our team is dedicated to delivering exceptional results, ensuring that your business operates at peak performance.