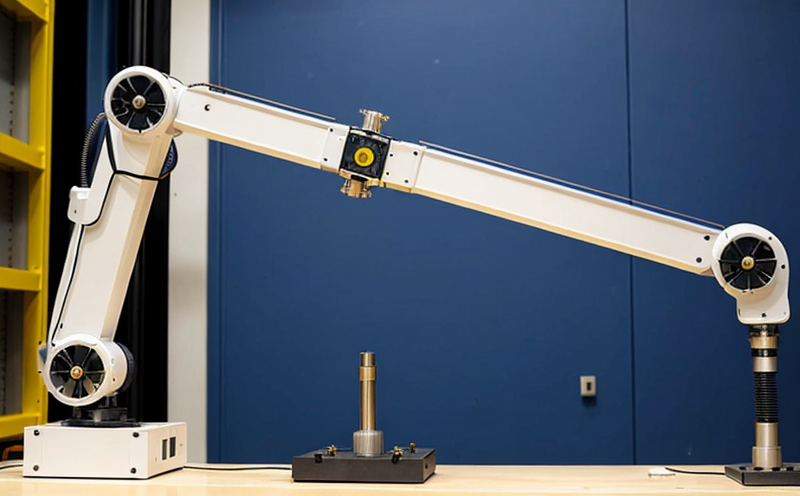

Testing the precision of axis motion in robotic arms

The Precision that Drives Industry Testing the Axis Motion of Robotic Arms

In todays era of automation and precision engineering, robotic arms have become an integral part of various industries such as manufacturing, healthcare, and logistics. These robotic arms are designed to perform complex tasks with high accuracy and speed, making them a crucial component in ensuring efficiency and productivity. However, like any other mechanical system, robotic arms can be prone to inaccuracies due to wear and tear or design flaws, which can lead to costly downtime and compromised product quality.

This is where Testing the precision of axis motion in robotic arms comes into play a laboratory service provided by Eurolab that helps businesses ensure their robotic arms are functioning at optimal levels. In this article, well delve into the world of robotic arm testing, exploring its importance, benefits, and how it can help your business thrive.

What is Testing the Precision of Axis Motion in Robotic Arms?

Testing the precision of axis motion in robotic arms involves a series of tests designed to evaluate the accuracy and repeatability of each axis (x, y, z) of the robotic arm. This includes measuring the deviation from the target position, as well as the resolution and stability of movement. The testing process typically involves using specialized equipment such as coordinate measurement machines (CMMs) or laser interferometers to accurately measure the motion of the robotic arm.

Why is Testing the Precision of Axis Motion in Robotic Arms Essential?

The precision of axis motion in robotic arms is critical for several reasons

Product Quality Inaccurate motion can lead to defects, scratches, and other quality issues that can compromise product integrity.

Efficiency A robotic arm with poor precision can cause unnecessary delays, reduce productivity, and increase energy consumption.

Safety Inaccurate motion can result in collisions, damage to equipment, or even injuries to personnel.

Advantages of Testing the Precision of Axis Motion in Robotic Arms

Testing the precision of axis motion in robotic arms offers numerous benefits for businesses

Improved Product Quality By identifying and correcting inaccuracies, you can ensure that your products meet quality standards.

Increased Efficiency Optimized robotic arm performance reduces downtime, increases productivity, and saves energy costs.

Enhanced Safety Preventing accidents and ensuring compliance with safety regulations helps protect personnel, equipment, and the environment.

Reduced Maintenance Costs Regular testing identifies potential issues before they become major problems, minimizing maintenance expenses.

Compliance with Industry Standards Demonstrating precision and accuracy ensures compliance with regulatory requirements and industry standards.

Key Benefits of Testing the Precision of Axis Motion in Robotic Arms

Here are some key benefits of using this laboratory service

Increased Uptime Reduce downtime caused by inaccurate motion or equipment failure.

Improved Productivity Optimize robotic arm performance to increase production capacity.

Reduced Energy Consumption Minimize energy waste due to inefficient movement.

Enhanced Competitiveness Demonstrate precision and accuracy in your products, setting you apart from competitors.

Cost Savings Reduce maintenance costs by identifying potential issues early on.

QA Testing the Precision of Axis Motion in Robotic Arms

Here are some frequently asked questions about testing the precision of axis motion in robotic arms

Q What is the typical turnaround time for this laboratory service?

A Our team works efficiently to ensure that results are delivered within a timely manner. However, the exact timeframe depends on the complexity of the tests and the availability of equipment.

Q Can I perform these tests in-house or do I need external assistance?

A While some businesses may have the expertise and resources to conduct these tests internally, many others benefit from outsourcing to Eurolabs experienced technicians and state-of-the-art facilities.

Q What types of robotic arms can be tested using this laboratory service?

A Our team specializes in testing a wide range of robotic arms, including those used in manufacturing, healthcare, logistics, and more.

Q How often should I test the precision of axis motion in my robotic arm?

A Regular testing (e.g., every 6-12 months) is recommended to ensure that your robotic arm remains accurate and efficient. However, this may vary depending on usage patterns and industry standards.

Conclusion

Testing the precision of axis motion in robotic arms is a critical aspect of ensuring the accuracy, efficiency, and safety of these essential machines. By choosing Eurolabs laboratory service, businesses can benefit from improved product quality, increased productivity, reduced maintenance costs, enhanced competitiveness, and compliance with industry standards. Dont let inaccurate motion compromise your business contact us today to learn more about how we can help you achieve precision that drives industry forward.

About Eurolab

Eurolab is a leading provider of laboratory services for various industries, specializing in testing the precision of axis motion in robotic arms. Our team of experienced technicians and experts use state-of-the-art equipment to deliver accurate results quickly and efficiently. With a commitment to quality and customer satisfaction, we help businesses worldwide ensure their products meet the highest standards of precision and accuracy.