Assessing Mechanical Endurance of Electronic Components

Assessing Mechanical Endurance of Electronic Components A Crucial Service for Businesses

In todays fast-paced and highly competitive business landscape, ensuring the reliability and longevity of electronic components is more crucial than ever. With the increasing complexity of electronic devices, manufacturers are constantly seeking ways to improve their products performance, efficiency, and lifespan. One critical aspect that often goes overlooked is the mechanical endurance of electronic components. At Eurolab, our laboratory service dedicated to Assessing Mechanical Endurance of Electronic Components helps businesses like yours identify potential weaknesses in their components, enabling them to make informed design decisions and minimize the risk of costly product failures.

What is Assessing Mechanical Endurance of Electronic Components?

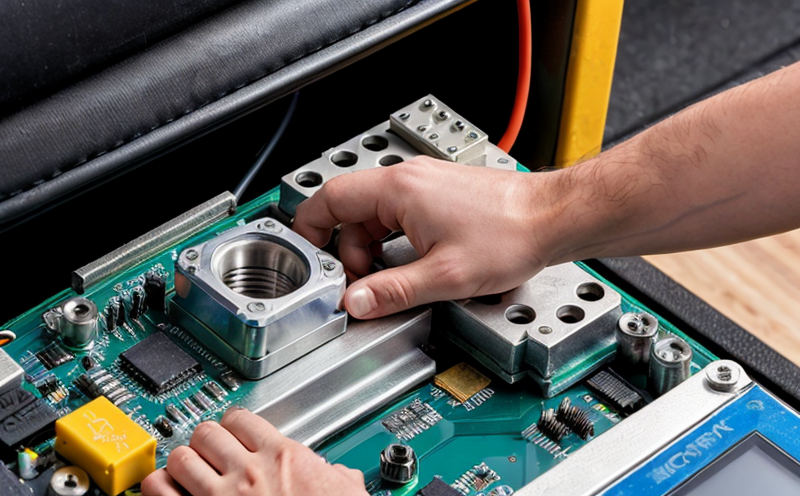

Assessing Mechanical Endurance of Electronic Components involves subjecting electronic parts to rigorous testing procedures that simulate real-world conditions. This includes exposing components to varying temperatures, humidity levels, vibration, and other environmental stressors. By doing so, our expert technicians can determine a components ability to withstand mechanical stress without compromising its functionality or structural integrity.

Why is Assessing Mechanical Endurance of Electronic Components Essential for Businesses?

Incorporating Assessing Mechanical Endurance of Electronic Components into your product development process offers numerous benefits that can significantly impact your business. Here are some key advantages

Improved Product Reliability By identifying potential mechanical weaknesses, you can design and manufacture products with improved reliability, reducing the likelihood of costly field failures.

Enhanced Customer Satisfaction Products that meet or exceed customer expectations regarding durability and performance contribute to increased customer satisfaction, leading to positive reviews, repeat business, and a stronger brand reputation.

Reduced Warranty Claims Assessing Mechanical Endurance helps minimize warranty claims by identifying potential issues early on in the design phase, reducing the financial burden associated with product recalls and repairs.

Compliance with Industry Standards Our service ensures that your products comply with industry standards and regulations, such as those set by regulatory bodies or industry organizations.

Cost Savings Identifying mechanical weaknesses during testing can help you avoid costly redesigns, production changes, or even complete product failures.

Key Benefits of Assessing Mechanical Endurance of Electronic Components

Here are some key benefits of our laboratory service in bullet points

Customized Testing Programs Our team works closely with your engineers to develop tailored testing programs that align with your specific requirements and industry standards.

Expert Analysis and Reporting We provide thorough analysis and detailed reports, highlighting areas for improvement and recommendations for design enhancements.

State-of-the-Art Equipment and Facilities Eurolabs modern laboratory is equipped with cutting-edge equipment and facilities, ensuring accurate and reliable results.

Rapid Turnaround Times Our streamlined testing processes enable quick turnaround times, allowing you to make informed design decisions in a timely manner.

Compliance with Industry Standards We adhere to industry standards and regulations, guaranteeing that your products meet or exceed regulatory requirements.

QA Frequently Asked Questions

Weve compiled some of the most commonly asked questions about Assessing Mechanical Endurance of Electronic Components. If you have any specific queries or concerns, please feel free to reach out to us

Q What types of electronic components can be tested for mechanical endurance?

A Our laboratory service is applicable to a wide range of electronic components, including but not limited to connectors, switches, relays, sensors, and printed circuit boards (PCBs).

Q How do you simulate real-world conditions during testing?

A We employ advanced simulation techniques that mimic various environmental stressors, such as temperature fluctuations, humidity levels, vibration, and shock.

Q What kind of reporting can I expect from Eurolabs Assessing Mechanical Endurance service?

A Our comprehensive reports provide detailed analysis, highlighting areas for improvement and recommendations for design enhancements. We also offer personalized consultations to discuss test results and answer any questions you may have.

Q How long does the testing process typically take?

A Turnaround times vary depending on the complexity of the testing program, but we strive to deliver accurate results within a reasonable timeframe, usually between 2-6 weeks.

Conclusion

In todays competitive business landscape, ensuring the mechanical endurance of electronic components is no longer a nicety its a necessity. By incorporating Assessing Mechanical Endurance of Electronic Components into your product development process, you can improve product reliability, enhance customer satisfaction, reduce warranty claims, and comply with industry standards. At Eurolab, our laboratory service provides expert analysis and reporting to help you make informed design decisions, minimizing the risk of costly product failures. Get in touch with us today to learn more about how our Assessing Mechanical Endurance of Electronic Components service can benefit your business.