Assessing Wear Resistance in High-Density Circuit Boards

Assessing Wear Resistance in High-Density Circuit Boards A Crucial Laboratory Service for Businesses

In todays fast-paced and highly competitive business landscape, the success of a company often depends on its ability to produce high-quality products that meet the evolving demands of customers. For manufacturers of electronic components, including high-density circuit boards (HDCBs), wear resistance is a critical parameter that can significantly impact product reliability and lifespan.

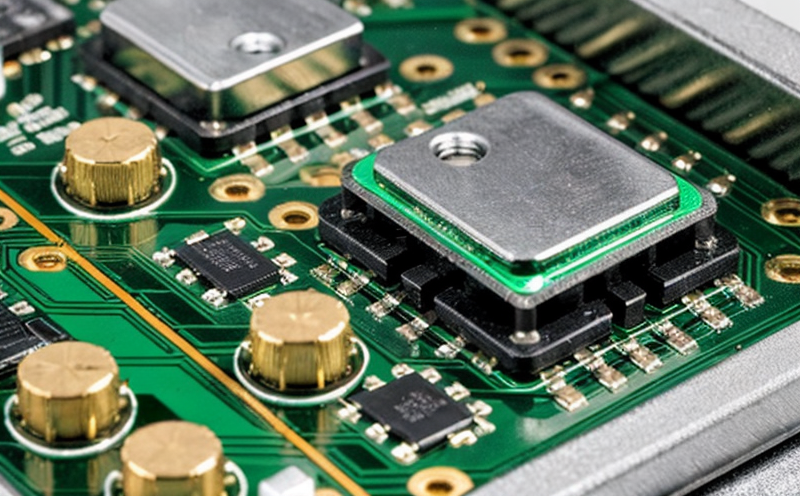

High-density circuit boards are an essential component in modern electronics, providing a compact and efficient way to integrate multiple components onto a single board. However, the increasing miniaturization and complexity of HDCBs have introduced new challenges, including heightened susceptibility to wear and tear. Wear resistance is the ability of a material or component to withstand friction-induced degradation without compromising its performance.

At Eurolab, our expert laboratory services specialize in assessing wear resistance in high-density circuit boards. In this article, we will delve into the importance of wear resistance testing for HDCBs and explore the benefits of partnering with us for this critical service.

The Importance of Wear Resistance in High-Density Circuit Boards

High-density circuit boards are subject to various forms of wear and tear during their operational life cycle. Some common factors that contribute to wear on HDCBs include

Thermal expansion and contraction, leading to mechanical stress and fatigue

Electrical overstress and current-induced thermal effects

Chemical exposure to moisture, humidity, or other environmental contaminants

Physical handling and transportation-related damage

As a result of these factors, HDCBs can experience degradation in electrical performance, mechanical integrity, and overall reliability. This wear and tear can lead to

Reduced product lifespan and increased maintenance costs

Increased failure rates and downtime for manufacturing processes

Escalating customer dissatisfaction due to decreased product performance

The Benefits of Assessing Wear Resistance in High-Density Circuit Boards with Eurolab

Partnering with Eurolab for wear resistance testing provides numerous benefits for businesses involved in the production of high-density circuit boards. Some key advantages include

Enhanced Product Reliability and Lifespan

Our comprehensive assessment services help identify areas where wear and tear are most likely to occur, enabling our clients to implement targeted improvements and optimize their products.

Improved Manufacturing Efficiency and Reduced Costs

By evaluating wear resistance in HDCBs during the design phase, manufacturers can make data-driven decisions to minimize production costs, reduce waste, and streamline processes.

Increased Customer Satisfaction and Trust

Demonstrating a commitment to quality and reliability through our laboratory services helps build trust with customers, leading to increased loyalty and repeat business opportunities.

Key Benefits of Assessing Wear Resistance in High-Density Circuit Boards

Reduced product failure rates Identify potential wear-related issues early on and take corrective action to prevent costly failures.

Improved manufacturing yield Maximize production efficiency by optimizing board design, materials, and processing techniques.

Enhanced customer satisfaction Offer high-quality products that meet or exceed customer expectations for performance, reliability, and lifespan.

QA Frequently Asked Questions about Assessing Wear Resistance in High-Density Circuit Boards

Q1 What is wear resistance, and why is it important for high-density circuit boards?

A1 Wear resistance refers to a materials ability to withstand friction-induced degradation without compromising its performance. For HDCBs, it is essential to ensure that the board can maintain its integrity over time, especially in demanding applications.

Q2 What types of wear and tear can high-density circuit boards experience during their operational life cycle?

A2 HDCBs are susceptible to various forms of wear, including thermal expansion and contraction, electrical overstress, chemical exposure, and physical handling-related damage.

Q3 How does Eurolabs laboratory service help businesses improve product reliability and lifespan?

A3 Our comprehensive assessment services identify areas where wear and tear are most likely to occur, enabling our clients to implement targeted improvements and optimize their products.

Q4 What types of benefits can I expect from partnering with Eurolab for wear resistance testing?

A4 By working with us, you can enjoy enhanced product reliability and lifespan, improved manufacturing efficiency and reduced costs, and increased customer satisfaction and trust.

At Eurolab, we are dedicated to providing expert laboratory services that help businesses like yours optimize their high-density circuit board designs and improve overall product performance. Contact us today to learn more about our wear resistance testing capabilities and schedule your assessment service.