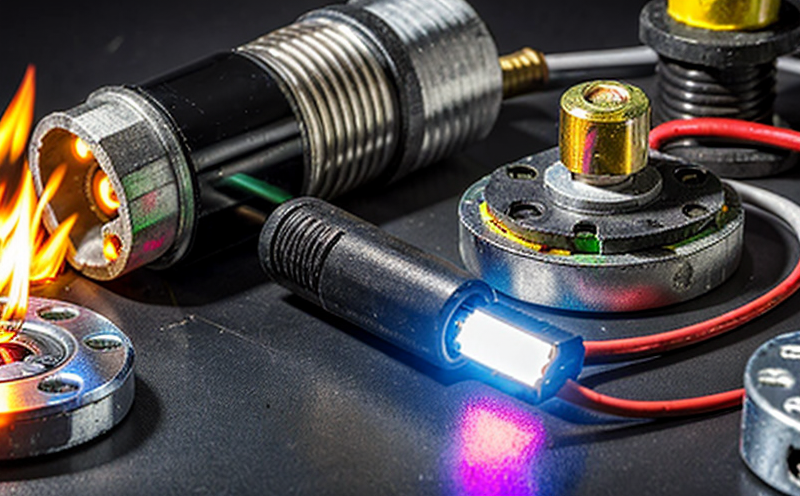

Assessing the safety of electrical components and circuits under thermal stress to prevent overheating and fires

The Crucial Role of Assessing Electrical Components Safety Under Thermal Stress Prevent Overheating and Fires

As businesses continue to operate in an increasingly complex technological landscape, the importance of ensuring electrical component safety cannot be overstated. One critical aspect of this is assessing the safety of electrical components and circuits under thermal stress to prevent overheating and fires. This laboratory service, offered by Eurolab, is a vital tool for organizations looking to safeguard their assets, protect their reputation, and comply with regulatory requirements.

What is Assessing the Safety of Electrical Components and Circuits Under Thermal Stress?

Thermal stress occurs when electrical components are exposed to extreme temperatures, either due to environmental conditions or operational factors. Prolonged exposure can cause overheating, leading to component failure, device malfunction, and potentially even catastrophic fires. Eurolabs laboratory service assesses the thermal stability of electrical components and circuits to identify potential risks and provide recommendations for mitigation.

Why is Assessing Electrical Components Safety Under Thermal Stress Essential?

The consequences of neglecting thermal stress assessment can be severe

Financial Loss Component failure or device malfunction can result in significant downtime, repair costs, and revenue loss.

Reputational Damage A single fire incident can irreparably damage a companys reputation, leading to loss of customer trust and business contracts.

Regulatory Non-Compliance Failure to adhere to industry standards for thermal stress testing can result in costly fines, penalties, and reputational damage.

Benefits of Using Eurolabs Assessing Electrical Components Safety Under Thermal Stress Service

Here are the key benefits of partnering with Eurolab

Proactive Risk Management Identify potential thermal stress risks before they become critical issues.

Compliance with Industry Standards Meet regulatory requirements for thermal stress testing, ensuring compliance and avoiding costly penalties.

Cost Savings Reduce downtime and repair costs associated with component failure or device malfunction.

Enhanced Reputation Demonstrate a commitment to safety and reliability, protecting your companys reputation and maintaining customer trust.

Key Benefits of Eurolabs Assessing Electrical Components Safety Under Thermal Stress Service

Here are the key benefits in bullet points

Customized Testing Programs Develop tailored testing programs that meet specific industry standards or regulatory requirements.

State-of-the-Art Equipment Utilize advanced equipment and techniques to ensure accurate and reliable results.

Expert Analysis Receive expert analysis and recommendations for mitigating thermal stress risks.

Rapid Turnaround Times Obtain test results quickly, ensuring timely decision-making and minimizing downtime.

Frequently Asked Questions (FAQs)

Here are some frequently asked questions about Eurolabs assessing electrical components safety under thermal stress service

Q What types of electrical components can be tested?

A Eurolabs laboratory service assesses a wide range of electrical components, including but not limited to

Electronic devices (e.g., smartphones, laptops)

Industrial equipment (e.g., motors, generators)

Aerospace components

Automotive systems

Q What types of thermal stress conditions can be simulated?

A Eurolabs laboratory service simulates various thermal stress conditions, including

High temperatures (up to 200C)

Low temperatures (down to -50C)

Rapid temperature changes

Cyclic loading and unloading

Q What is the typical turnaround time for test results?

A Eurolabs laboratory service typically provides rapid turnaround times, with most tests completed within 1-3 business days.

Conclusion

In conclusion, assessing the safety of electrical components and circuits under thermal stress to prevent overheating and fires is a critical aspect of ensuring electrical component safety. By partnering with Eurolab, organizations can proactively identify potential risks, ensure compliance with industry standards, reduce costs associated with component failure or device malfunction, and enhance their reputation.

-

Testing the ability of consumer products to withstand high temperatures without failure or malfunction

-

Evaluating the heat resistance of materials used in products such as electronics, automotive parts, and packaging

-

Simulating extreme temperature conditions to assess how products perform in hot or cold environments

-

Verifying the effectiveness of thermal insulation materials used in products like cooking appliances, clothing, or packaging

-

Testing the impact of thermal cycling, where products are subjected to repeated heating and cooling, on their durability

-

Assessing the ability of electronic devices to operate safely under high temperature conditions

-

Simulating heat exposure for materials like plastics, rubbers, and metals to assess their long-term durability and performance

-

Testing the thermal conductivity of products or components to determine their ability to resist or dissipate heat

-

Evaluating the performance of cooling systems used in electronic devices, automobiles, or industrial equipment under varying temperatures

-

Simulating the effects of high temperatures on the physical properties of materials, such as deformation, melting, or discoloration

-

Testing products for their ability to maintain their functionality and appearance after exposure to extreme heat or cold

-

Verifying the heat resistance of adhesives, coatings, and seals used in products subjected to temperature fluctuations

-

Assessing the impact of thermal stress on components, such as electrical connectors or mechanical parts, during heating cycles

-

Simulating the performance of packaging materials when exposed to hot environments or high temperature transport conditions

-

Testing the ability of products to maintain their strength and integrity under high-temperature stress, such as in engines or motors

-

Evaluating the performance of fabrics, textiles, and insulation materials in resisting heat damage and maintaining comfort

-

Simulating the thermal shock that occurs when a product is rapidly cooled or heated to assess its resilience

-

Verifying that consumer products maintain their safety and function when subjected to extreme temperature changes

-

Testing the resilience of materials to thermal aging, which can cause breakdown or wear over time due to heat exposure

-

Simulating high-temperature conditions in automotive or aerospace industries to test the thermal endurance of parts and systems