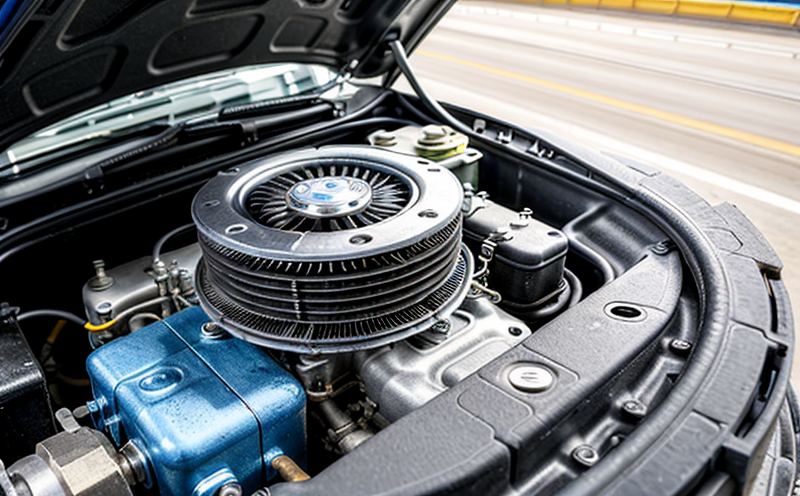

Testing the ability of products to maintain their strength and integrity under high-temperature stress, such as in engines or motors

Testing the Unyielding Strength Ensuring Products withstanding High-Temperature Stress

In the world of engineering and manufacturing, products are designed to perform under various conditions. However, one critical aspect that demands attention is their ability to maintain strength and integrity when subjected to high-temperature stress. This phenomenon is particularly significant in industries where engines, motors, and other machinery operate at extreme temperatures.

What is High-Temperature Stress Testing?

High-temperature stress testing involves evaluating the capacity of a product to withstand elevated temperatures without compromising its structural integrity or mechanical properties. This process simulates the conditions encountered by components in real-world applications, such as internal combustion engines, jet engines, and electric motors.

At Eurolab, our team of experts specializes in providing high-quality laboratory services for testing the ability of products to maintain their strength and integrity under high-temperature stress. We recognize that ensuring the reliability and longevity of products is crucial for businesses across various sectors.

The Importance of High-Temperature Stress Testing

High-temperature stress testing offers numerous benefits for manufacturers, designers, and users of products operating in extreme conditions

Ensures product performance and lifespan By simulating high-temperature environments, we can determine whether a products design and materials meet the required standards. This helps guarantee its efficiency and durability over time.

Identifies material limitations High-temperature stress testing reveals the temperature-dependent properties of various materials, allowing manufacturers to select the best-suited materials for their applications.

Reduces risks and costs By conducting these tests, businesses can avoid costly redesigns, rework, or even product recalls. This approach also minimizes the risk of product failure, which can lead to financial losses and damage to reputation.

Advantages of Partnering with Eurolab for High-Temperature Stress Testing

Partnering with Eurolab offers numerous advantages for companies seeking high-quality laboratory services

Comprehensive testing capabilities Our state-of-the-art equipment and expert personnel enable us to perform a wide range of tests, from accelerated aging to thermal shock.

Customized test protocols We work closely with clients to develop tailored testing strategies that meet their specific needs and product requirements.

Fast turnaround times Our streamlined processes ensure quick results, allowing businesses to make informed decisions about product development and deployment.

Expert interpretation of results Our team provides detailed reports and recommendations for product improvement, empowering companies to optimize their products performance.

Key Benefits of High-Temperature Stress Testing

Here are the key benefits of high-temperature stress testing in bullet points

Improved product reliability

Enhanced lifespan and durability

Reduced maintenance and repair costs

Increased confidence in product performance

Compliance with industry standards and regulations

Competitive advantage through innovative designs

Frequently Asked Questions (FAQs)

Q What types of products can be tested for high-temperature stress?

A We test a wide range of products, including engine components, motor parts, heat exchangers, and other machinery elements.

Q How long does the testing process typically take?

A The duration of testing depends on the specific requirements of each project. However, our team ensures that results are delivered in a timely manner to meet your business needs.

Q Can you provide customized test protocols for unique product applications?

A Yes, we collaborate with clients to develop tailored testing strategies that address their specific concerns and product specifications.

Q Do you offer any certification or documentation services following the testing process?

A Yes, our team provides comprehensive reports, certificates of compliance, and other documentation as required by regulatory bodies or industry standards.

Conclusion

Testing a products ability to maintain its strength and integrity under high-temperature stress is an essential aspect of ensuring their performance and lifespan. At Eurolab, we specialize in providing laboratory services that cater to the needs of businesses operating in extreme conditions. By partnering with us, companies can benefit from our expertise, state-of-the-art equipment, and customized testing protocols. Contact us today to learn more about how we can help you achieve product excellence.

-

Testing the ability of consumer products to withstand high temperatures without failure or malfunction

-

Evaluating the heat resistance of materials used in products such as electronics, automotive parts, and packaging

-

Simulating extreme temperature conditions to assess how products perform in hot or cold environments

-

Verifying the effectiveness of thermal insulation materials used in products like cooking appliances, clothing, or packaging

-

Testing the impact of thermal cycling, where products are subjected to repeated heating and cooling, on their durability

-

Assessing the ability of electronic devices to operate safely under high temperature conditions

-

Simulating heat exposure for materials like plastics, rubbers, and metals to assess their long-term durability and performance

-

Testing the thermal conductivity of products or components to determine their ability to resist or dissipate heat

-

Evaluating the performance of cooling systems used in electronic devices, automobiles, or industrial equipment under varying temperatures

-

Simulating the effects of high temperatures on the physical properties of materials, such as deformation, melting, or discoloration

-

Testing products for their ability to maintain their functionality and appearance after exposure to extreme heat or cold

-

Verifying the heat resistance of adhesives, coatings, and seals used in products subjected to temperature fluctuations

-

Assessing the impact of thermal stress on components, such as electrical connectors or mechanical parts, during heating cycles

-

Simulating the performance of packaging materials when exposed to hot environments or high temperature transport conditions

-

Evaluating the performance of fabrics, textiles, and insulation materials in resisting heat damage and maintaining comfort

-

Simulating the thermal shock that occurs when a product is rapidly cooled or heated to assess its resilience

-

Verifying that consumer products maintain their safety and function when subjected to extreme temperature changes

-

Testing the resilience of materials to thermal aging, which can cause breakdown or wear over time due to heat exposure

-

Assessing the safety of electrical components and circuits under thermal stress to prevent overheating and fires

-

Simulating high-temperature conditions in automotive or aerospace industries to test the thermal endurance of parts and systems