Coating performance under drop impact tests

Unlocking the Secrets of Coating Performance Why Drop Impact Tests Matter for Your Business

As a business owner in the coatings industry, youre likely no stranger to the importance of ensuring your products can withstand various forms of impact and stress. Whether its protecting surfaces from scratches, corrosion, or damage, coatings play a vital role in maintaining the integrity and performance of materials.

However, with the increasing demand for high-performance coatings that can resist even the most extreme conditions, its become crucial to assess their capabilities under realistic scenarios. This is where Coating Performance under Drop Impact Tests come into play a laboratory service offered by Eurolab that simulates real-world drop impacts to evaluate coating performance.

In this article, well delve into the world of Coating Performance under Drop Impact Tests and explore why its an essential tool for businesses like yours. From understanding the significance of this testing method to uncovering its numerous advantages, well cover everything you need to know to make informed decisions about your product development process.

What is Coating Performance under Drop Impact Tests?

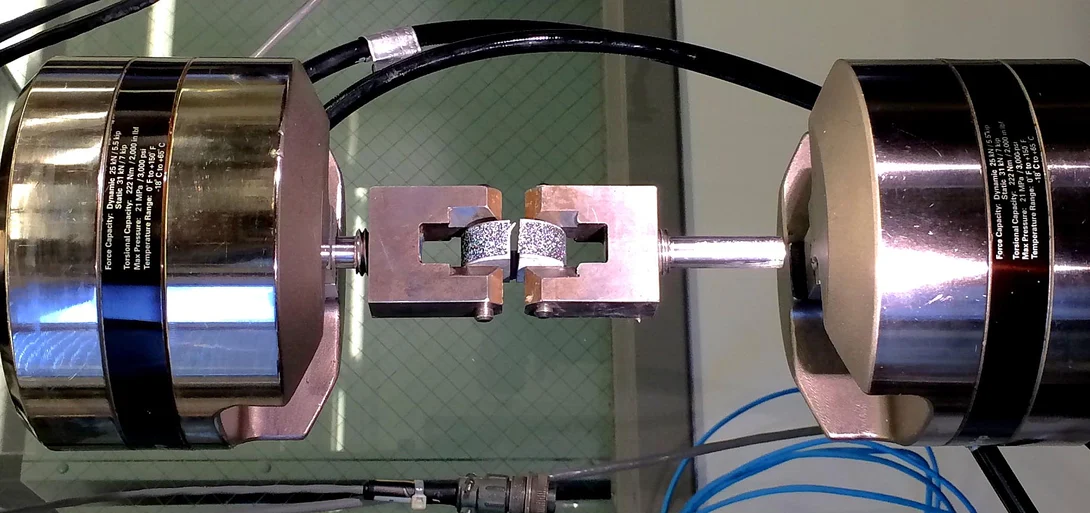

Coating Performance under Drop Impact Tests involves subjecting coated samples to a controlled drop impact, simulating real-world scenarios where coatings are subjected to sudden impacts. This laboratory service utilizes specialized equipment that replicates the forces and stresses encountered during actual drops or falls. The test evaluates how well the coating performs in terms of

Adhesion How securely the coating adheres to the substrate.

Flexibility How well the coating withstands deformation without cracking or failing.

Impact resistance The ability of the coating to resist damage from sudden impacts.

Why is Coating Performance under Drop Impact Tests Essential for Businesses?

As the coatings industry continues to evolve, manufacturers face growing demands for products that can perform consistently in various environments. Conducting drop impact tests helps companies like yours

Ensure product safety Protect consumers and your brand reputation by verifying coating performance under real-world conditions.

Improve product durability Develop coatings with enhanced resistance to damage from drops, scratches, or other forms of stress.

Enhance material compatibility Understand how different materials interact with your coatings, enabling informed decisions on substrate selection.

Reduce warranty claims Minimize liability and costs associated with damaged products by identifying areas for improvement.

Advantages of Using Coating Performance under Drop Impact Tests

Here are the key benefits of incorporating drop impact testing into your product development process

Real-world relevance Simulates actual conditions, ensuring test results accurately reflect real-world performance.

Cost savings Identifies and addresses coating weaknesses before they become a liability, reducing potential costs associated with damage or warranty claims.

Quality improvement Enables the development of high-performance coatings that meet stringent industry standards.

Compliance Ensures your products comply with regulatory requirements, such as those related to safety and environmental protection.

Frequently Asked Questions

Weve compiled a list of commonly asked questions to help you better understand Coating Performance under Drop Impact Tests

What types of coatings can be tested?

Eurolab offers drop impact testing for various coating materials, including paints, varnishes, and powder coatings.

How does the testing process work?

Our expert technicians carefully prepare coated samples, subject them to a controlled drop impact using specialized equipment, and record the results.

What kind of data can I expect from the test?

Youll receive detailed reports outlining coating performance in terms of adhesion, flexibility, and impact resistance.

Can I customize testing parameters?

Yes, we offer flexible testing protocols to accommodate your specific needs.

Why Choose Eurolab for Coating Performance under Drop Impact Tests?

At Eurolab, were dedicated to providing industry-leading laboratory services that meet the evolving demands of businesses like yours. Our

Expertise Trained technicians with extensive experience in coatings testing and analysis.

State-of-the-art equipment Cutting-edge technology ensures accurate, reliable results.

Comprehensive reporting Detailed reports outlining test findings, enabling informed decision-making.

Dont compromise on the performance and safety of your coatings. Contact Eurolab today to learn more about Coating Performance under Drop Impact Tests and take the first step towards developing high-performance coatings that meet real-world demands.