Impact resistance testing for coatings on glass surfaces

The Importance of Impact Resistance Testing for Coatings on Glass Surfaces Why Your Business Needs It

In todays fast-paced world, the demand for innovative and durable products is higher than ever. With the increasing use of glass surfaces in various applications, from architecture to automotive, ensuring the integrity and durability of these coatings has become a top priority. One crucial aspect of coating evaluation is Impact resistance testing for coatings on glass surfaces a laboratory service that separates industry leaders from mere contenders.

At Eurolab, we understand the significance of reliable and robust coatings that can withstand the rigors of everyday use. Thats why our expert technicians specialize in providing comprehensive impact testing services to help manufacturers and suppliers ensure their products meet stringent standards and specifications. In this article, well delve into the importance of Impact resistance testing for coatings on glass surfaces and explore its benefits for businesses.

What is Impact Resistance Testing for Coatings on Glass Surfaces?

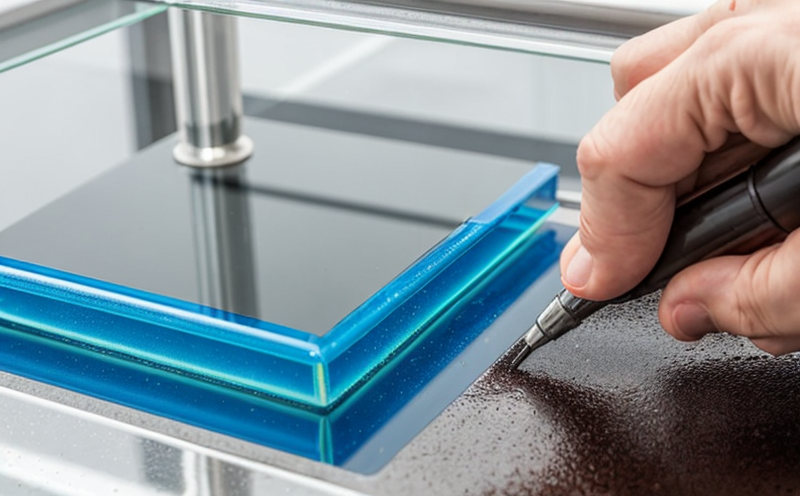

Impact resistance testing evaluates a coatings ability to resist damage from external forces, such as drops or impacts. This type of testing is particularly relevant for glass surfaces, which are increasingly being used in various applications due to their unique properties strength, transparency, and scratch-resistance.

The process involves subjecting the coated glass surface to controlled impact tests, simulating real-world scenarios that might cause damage. Our expert technicians use advanced equipment and techniques to accurately measure the coatings performance under various conditions. The results provide a clear understanding of the coatings resistance to impacts, allowing manufacturers to identify areas for improvement and optimize their products.

Why is Impact Resistance Testing Essential for Your Business?

In todays competitive market, reliability and durability are no longer mere luxuries theyre essential differentiators. Companies that prioritize impact testing can

Reduce product failures By identifying potential weaknesses in their coatings, manufacturers can minimize the risk of product failure, saving time and resources.

Improve customer satisfaction A durable coating ensures customers receive a high-quality product that meets their expectations, fostering loyalty and positive word-of-mouth marketing.

Enhance brand reputation Companies that invest in rigorous testing demonstrate their commitment to quality, reinforcing their brands reputation for excellence.

Gain a competitive edge By offering superior coatings with enhanced impact resistance, businesses can differentiate themselves from competitors and attract premium customers.

The Benefits of Impact Resistance Testing

Our comprehensive impact testing services offer numerous benefits to manufacturers, including

Improved product reliability

Enhanced customer satisfaction

Increased brand reputation

Competitive advantage

Reduced warranty claims

Compliance with industry standards

Cost savings through optimized production processes

QA Frequently Asked Questions about Impact Resistance Testing for Coatings on Glass Surfaces

Q What types of glass surfaces can be tested?

A Our expert technicians can test a wide range of glass surfaces, including laminated, tempered, and annealed glass.

Q How is the impact testing process performed?

A We use advanced equipment and techniques to simulate real-world scenarios, subjecting the coated glass surface to controlled impacts. The results provide accurate measurements of the coatings performance.

Q What information can I expect from the test results?

A Our comprehensive report includes detailed analysis of the coatings impact resistance, highlighting areas for improvement and suggesting optimization strategies.

Q Are your technicians experienced in testing coatings on glass surfaces?

A Yes. Our expert technicians specialize in impact testing for coatings on glass surfaces, ensuring accurate and reliable results.

Q Can I schedule a test at my facility or do I need to send the sample to Eurolab?

A We offer both in-house testing at our state-of-the-art facilities and on-site testing services, allowing manufacturers to choose the most convenient option for their needs.

Conclusion

In todays demanding market, ensuring the integrity and durability of coatings on glass surfaces is crucial for businesses. Impact resistance testing provides a clear understanding of a coatings performance under various conditions, enabling manufacturers to optimize their products and stay ahead of competitors.

At Eurolab, our expert technicians specialize in providing comprehensive impact testing services that separate industry leaders from mere contenders. With our cutting-edge equipment and techniques, we help manufacturers reduce product failures, improve customer satisfaction, and enhance brand reputation. By investing in reliable and robust coatings with enhanced impact resistance, businesses can gain a competitive edge and establish themselves as industry pioneers.

Contact us today to learn more about how Eurolabs Impact resistance testing for coatings on glass surfaces can benefit your business.

About Eurolab

Eurolab is a leading laboratory services provider specializing in impact testing for coatings on glass surfaces. Our expert technicians use advanced equipment and techniques to deliver accurate and reliable results, helping manufacturers optimize their products and stay ahead of competitors. With our comprehensive services, businesses can ensure the integrity and durability of their coatings, reducing product failures and improving customer satisfaction.

Stay Ahead with Eurolab

Join the ranks of industry leaders who trust Eurolabs expert technicians for their impact testing needs. Contact us today to schedule a test or learn more about how our laboratory services can benefit your business.