Component Stress Testing in High-Humidity Environments

Component Stress Testing in High-Humidity Environments A Crucial Service for Businesses

In todays fast-paced and competitive business landscape, ensuring the reliability and durability of electronic components is more crucial than ever. With the rise of IoT devices, wearables, and other connected technologies, the demand for high-performance electronics has skyrocketed. However, this increased demand also poses significant challenges in terms of component lifespan and failure rates.

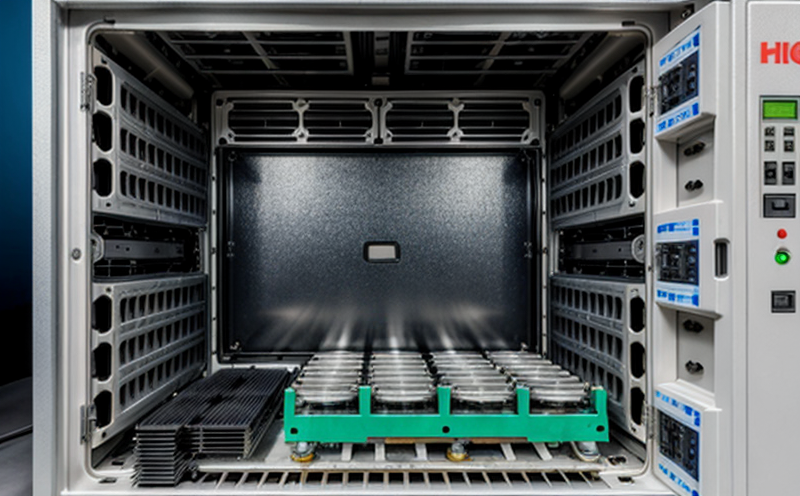

One critical aspect that can significantly impact component performance is exposure to high-humidity environments. Moisture can seep into electronic components, causing corrosion, oxidation, and ultimately leading to catastrophic failures. This is where Component Stress Testing in High-Humidity Environments comes in a laboratory service provided by Eurolab that simulates real-world conditions to test the resilience of your components.

What is Component Stress Testing in High-Humidity Environments?

Component Stress Testing in High-Humidity Environments involves subjecting electronic components to controlled humidity levels, typically between 30 to 95, along with temperature fluctuations and other stressors. This rigorous testing process enables us to evaluate the performance of your components under extreme conditions, mimicking real-world scenarios such as marine environments, tropical climates, or humid industrial settings.

Why is Component Stress Testing in High-Humidity Environments essential for businesses?

In todays globalized economy, companies must ensure their products can withstand diverse environmental conditions. Here are some compelling reasons why Component Stress Testing in High-Humidity Environments is a crucial service

Improved Product Reliability By testing components in high-humidity environments, you can identify potential failure points and design improvements to enhance overall product reliability.

Reduced Warranty Claims and Costs Components that pass the stress test are less likely to fail under real-world conditions, reducing warranty claims and associated costs.

Compliance with Industry Standards Component Stress Testing in High-Humidity Environments helps you meet industry-specific standards for environmental testing, such as MIL-STD-883 or IEC 60068-2-

Increased Customer Confidence By demonstrating your commitment to quality and reliability through rigorous testing, you can establish trust with customers and differentiate your brand in a competitive market.

Key Benefits of Component Stress Testing in High-Humidity Environments

Here are some key benefits of using our Component Stress Testing in High-Humidity Environments service

Thorough Evaluation Our comprehensive testing process assesses component performance under extreme humidity levels, ensuring you can design and manufacture products that meet your customers expectations.

Customized Testing Solutions We offer tailored testing programs to accommodate specific requirements for various industries, such as aerospace, automotive, or medical devices.

Accelerated Test Methods By leveraging accelerated test methods, we can simulate extended periods of high-humidity exposure in a fraction of the time, saving you valuable resources and accelerating your product development cycle.

Comprehensive Reporting and Analysis Our expert team provides detailed reports and analysis, enabling you to understand the performance of your components under high-humidity conditions.

QA Section

Here are some frequently asked questions about Component Stress Testing in High-Humidity Environments

What types of components can be tested?

We test a wide range of electronic components, including ICs, semiconductors, sensors, and connectors.

How long does the testing process take?

The duration of the testing process varies depending on the specific requirements of your components. However, we typically complete tests within 2-4 weeks.

Can I customize the test protocol to meet my industrys standards?

Absolutely! Our team will work closely with you to develop a customized testing plan that meets your specific needs and complies with relevant industry standards.

Do you provide any analysis or reporting services?

Yes, we offer comprehensive reporting and analysis services to help you understand the performance of your components under high-humidity conditions.

Conclusion

Component Stress Testing in High-Humidity Environments is a critical service that ensures the reliability and durability of electronic components in diverse environmental conditions. By partnering with Eurolab, you can trust that your products will withstand the rigors of real-world applications, providing confidence to your customers and establishing your brand as a leader in quality and innovation.

Dont compromise on product performance or reliability choose Component Stress Testing in High-Humidity Environments from Eurolab today!