Testing for Durability of Connectors Under Stress Conditions

Testing for Durability of Connectors Under Stress Conditions Ensuring the Reliability of Your Products

In todays fast-paced and increasingly complex industrial landscape, the reliability and durability of connectors are more critical than ever. As products become smaller, more sophisticated, and interconnected, the risks associated with faulty connections grow exponentially. One minor miscalculation or oversight can lead to catastrophic failures, costly downtime, and irreparable damage to your brands reputation.

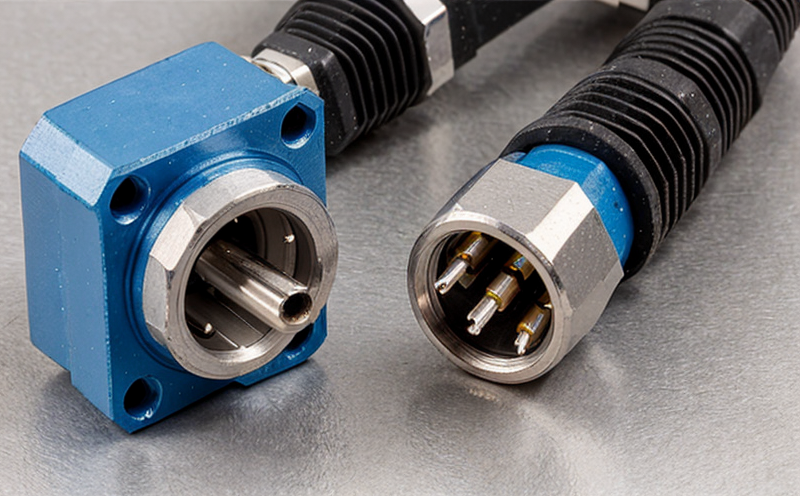

To mitigate these risks, Eurolab offers a cutting-edge laboratory service Testing for Durability of Connectors Under Stress Conditions. This comprehensive testing program simulates real-world conditions to evaluate the performance of connectors under extreme stress, ensuring that they can withstand even the most demanding environments.

The Importance of Testing for Durability of Connectors

In todays hyper-competitive marketplace, manufacturers and engineers are constantly pushing the boundaries of innovation and efficiency. However, this pursuit of excellence often comes with unforeseen consequences. As connectors are subjected to increasing stresses, temperatures, and vibrations, their reliability begins to degrade.

Testing for Durability of Connectors Under Stress Conditions is an essential step in ensuring that your products meet the required standards of quality and performance. By simulating real-world conditions, this testing process allows you to

Identify potential weaknesses and vulnerabilities

Optimize connector design and material selection

Improve overall product reliability and lifespan

Reduce warranty claims and returns

Enhance customer satisfaction and confidence

The Benefits of Testing for Durability of Connectors Under Stress Conditions

Eurolabs Testing for Durability of Connectors Under Stress Conditions provides a comprehensive suite of benefits, including

Improved Product Reliability By simulating real-world conditions, our testing process helps identify potential weaknesses and vulnerabilities in your connectors.

Reduced Warranty Claims By optimizing connector design and material selection, you can reduce the likelihood of product failures and associated warranty claims.

Increased Customer Satisfaction By ensuring that your products meet the required standards of quality and performance, you can enhance customer satisfaction and confidence.

Enhanced Product Lifespan Our testing process helps identify areas for improvement, enabling you to optimize connector design and material selection for longer lifespan.

Compliance with Industry Standards Our comprehensive testing program ensures that your products comply with relevant industry standards and regulations.

Cost Savings By identifying potential issues early on, you can avoid costly rework, redesigns, and manufacturing delays.

Competitive Advantage By demonstrating a commitment to product quality and reliability, you can differentiate yourself from competitors and establish a reputation for excellence.

A Closer Look at the Testing Process

Eurolabs Testing for Durability of Connectors Under Stress Conditions involves a comprehensive evaluation of your connectors performance under extreme stress conditions. Our experienced technicians subject your products to

Temperature cycling simulating temperature fluctuations between -40C and 125C

Vibration testing replicating the effects of mechanical stress, such as those encountered in transportation or construction equipment

Shock and impact testing simulating sudden impacts or drops that can damage connectors

Moisture ingress testing evaluating the connectors resistance to water and humidity

Life cycle testing simulating the cumulative effect of repeated stress cycles on connector performance

Frequently Asked Questions

We understand that you may have questions about Testing for Durability of Connectors Under Stress Conditions. Here are some answers to frequently asked questions

Q What types of connectors can be tested?

A Eurolabs testing service is applicable to a wide range of connectors, including those used in electronic, mechanical, and industrial applications.

Q How long does the testing process typically take?

A The duration of our testing program varies depending on the specific requirements of your project. Contact us for more information.

Q Can I customize the testing protocol to meet my specific needs?

A Yes, we offer tailored testing programs that cater to your unique requirements and industry standards.

Q What kind of data and reports can I expect from the testing process?

A Our comprehensive testing program generates detailed reports on connector performance, including stress levels, material fatigue, and potential weaknesses.

Conclusion

In todays fast-paced industrial landscape, ensuring the reliability and durability of connectors is crucial to product success. Eurolabs Testing for Durability of Connectors Under Stress Conditions offers a cutting-edge laboratory service that simulates real-world conditions to evaluate connector performance under extreme stress. By investing in this comprehensive testing program, you can

Improve product reliability and lifespan

Reduce warranty claims and returns

Enhance customer satisfaction and confidence

Establish a reputation for excellence

Dont compromise on the quality and reliability of your products. Contact Eurolab today to learn more about our Testing for Durability of Connectors Under Stress Conditions service.