Corrosion testing of metal and alloy components

The Importance of Corrosion Testing for Metal and Alloy Components Protecting Your Business with Eurolabs Expert Services

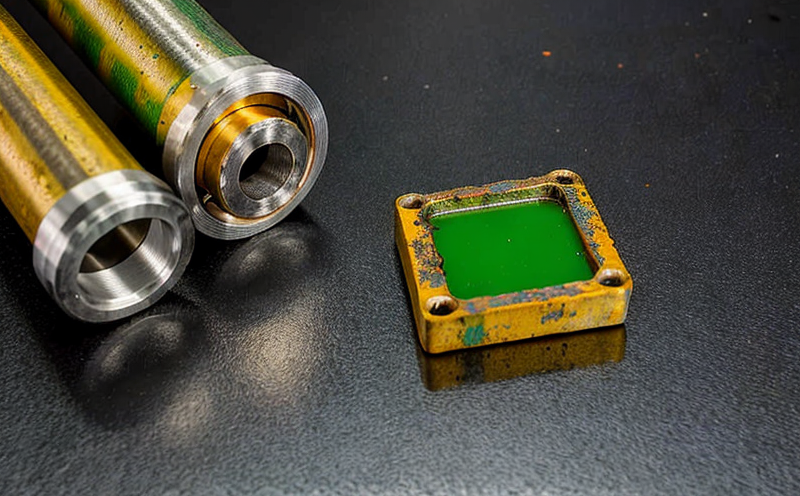

Corrosion testing of metal and alloy components is a critical process that ensures the durability and reliability of materials used in various industries, including aerospace, automotive, energy, construction, and more. At Eurolab, our laboratory experts offer comprehensive corrosion testing services to help businesses identify potential issues and mitigate risks associated with material degradation.

In this article, we will delve into the significance of corrosion testing, its benefits, and the importance of partnering with a reputable laboratory like Eurolab to ensure the integrity of your metal and alloy components.

What is Corrosion Testing?

Corrosion testing involves evaluating the susceptibility of metals and alloys to corrosion under various environmental conditions. This process helps manufacturers and engineers understand how materials will behave in different situations, reducing the likelihood of premature failure or unexpected performance issues.

Our expert technicians at Eurolab use a range of advanced techniques and equipment to simulate real-world scenarios and assess the resistance of metal and alloy components to corrosion. By identifying potential weaknesses, we enable businesses to take corrective action, ensuring their products meet industry standards and regulatory requirements.

Why is Corrosion Testing Essential for Businesses?

The benefits of corrosion testing are multifaceted and far-reaching

Prevents Equipment Failure Corrosion can cause equipment failure, resulting in costly downtime, production losses, and potential safety hazards. Regular testing helps identify areas of concern, allowing businesses to implement preventative measures.

Ensures Compliance with Industry Standards Many industries have strict regulations governing material selection and performance. Corrosion testing ensures that metal and alloy components meet or exceed these standards, reducing the risk of non-compliance and associated penalties.

Improves Material Selection By evaluating the corrosion resistance of materials under various conditions, businesses can make informed decisions about material selection, optimizing product performance, and minimizing maintenance costs.

Enhances Product Reliability Corrosion testing helps identify potential weaknesses in metal and alloy components, enabling manufacturers to take corrective action before products reach the market. This ensures that products meet customer expectations and industry standards.

Key Benefits of Using Corrosion Testing Services from Eurolab

Our corrosion testing services offer numerous advantages

Comprehensive Range of Tests We perform a wide range of tests, including salt spray, humidity, and accelerated corrosion testing, to simulate various environmental conditions.

Expert Analysis and Reporting Our experienced technicians provide detailed reports and expert analysis, ensuring that businesses understand the results and can take informed decisions.

Accurate Results We use advanced equipment and techniques to ensure accurate and reliable test results, giving businesses confidence in their material selection and performance.

Timely Delivery Our efficient testing process ensures rapid turnaround times, allowing businesses to quickly address any issues and meet production schedules.

Frequently Asked Questions (FAQs)

Q What types of materials can be tested for corrosion?

A We test a wide range of metal and alloy components, including steel, aluminum, copper, titanium, and more.

Q How do you simulate real-world conditions in the laboratory?

A Our expert technicians use advanced equipment and techniques to replicate various environmental conditions, such as salt spray, humidity, and temperature fluctuations.

Q What kind of information can I expect from a corrosion testing report?

A Our comprehensive reports include detailed results, analysis, and recommendations for material selection or improvement.

Q Can you perform custom testing according to specific industry standards or requirements?

A Yes, we offer customized testing services to meet the unique needs of your business and industry.

Conclusion

Corrosion testing is a critical process that ensures the reliability and durability of metal and alloy components. By partnering with Eurolab, businesses can benefit from our expert services, advanced equipment, and comprehensive range of tests. Our team of experienced technicians provides accurate results, detailed analysis, and timely reporting, empowering businesses to make informed decisions about material selection and performance.

Dont risk the integrity of your products or business operations. Contact us today to learn more about our corrosion testing services and how Eurolab can help you protect your business from the effects of corrosion.