Impact of corrosion testing on material selection

The Impact of Corrosion Testing on Material Selection Unlocking the Secrets to Sustainable and Efficient Business Operations

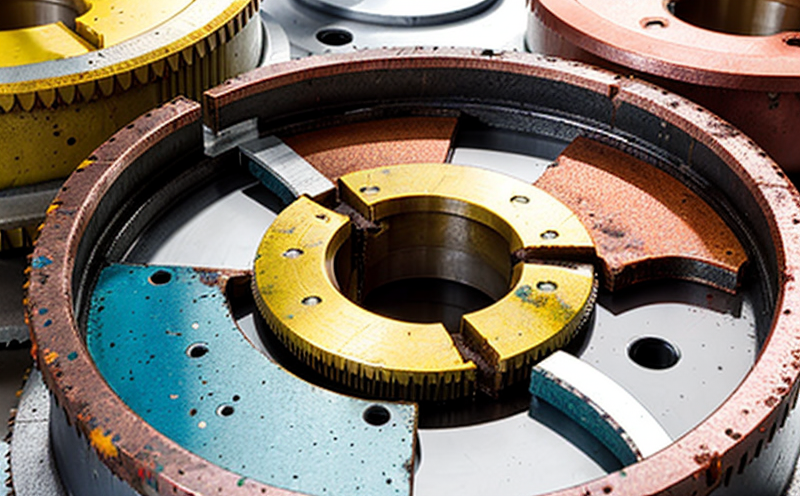

In todays competitive business landscape, companies are constantly seeking ways to optimize their operations, reduce costs, and increase efficiency. One crucial aspect that often goes overlooked is material selection. Choosing the right materials for your products or infrastructure can make all the difference between success and failure. Corrosion testing, a laboratory service provided by Eurolab, plays a vital role in ensuring that materials are suitable for their intended applications.

What is Impact of Corrosion Testing on Material Selection?

Corrosion testing is the process of evaluating the susceptibility of materials to corrosion under various environmental conditions. This involves simulating real-world scenarios to assess how different materials react when exposed to corrosive substances, temperature fluctuations, and other factors that can affect their durability. The primary objective of corrosion testing is to determine whether a material will withstand the rigors of its intended use without compromising its integrity.

The Importance of Corrosion Testing in Material Selection

Corrosion testing is essential for businesses operating in various industries, including construction, manufacturing, energy, and transportation. Here are some compelling reasons why

Cost Savings By identifying potential material weaknesses through corrosion testing, companies can avoid costly rework or replacements down the line.

Increased Efficiency Corrosion testing helps ensure that materials meet specific performance requirements, enabling businesses to streamline their production processes and reduce waste.

Improved Safety Corrosion-resistant materials are critical in industries where safety is paramount. Testing helps identify potential hazards and mitigate risks associated with material failure.

Compliance with Regulations Many industries have strict guidelines governing the selection of materials for specific applications. Corrosion testing ensures that companies comply with these regulations, minimizing the risk of non-compliance.

Key Benefits of Using Impact of Corrosion Testing on Material Selection

Here are some key benefits of incorporating corrosion testing into your material selection process

Enhanced Product Reliability By evaluating materials resistance to corrosion, businesses can ensure that their products or infrastructure meet performance expectations.

Extended Service Life Corrosion-resistant materials help extend the lifespan of products and structures, reducing maintenance costs and minimizing downtime.

Environmental Sustainability Choosing materials with low environmental impact contributes to a more sustainable future. Corrosion testing helps companies select materials that are less likely to contaminate soil or water.

Competitive Advantage Businesses that prioritize material selection through corrosion testing can differentiate themselves from competitors, establishing a reputation for quality and reliability.

Frequently Asked Questions (FAQs)

Here are some answers to common questions about impact of corrosion testing on material selection

What types of materials can be tested?

Corrosion testing is applicable to various materials, including metals, alloys, polymers, ceramics, and composites.

How do I prepare samples for testing?

Eurolab provides guidance on sample preparation, ensuring that materials are properly cleaned, cut, and handled before testing.

What types of corrosion tests can be performed?

A range of corrosion tests is available, including salt spray, acidic immersion, and cyclic exposure.

How long does the testing process take?

The duration of the testing process depends on the specific test method and material being evaluated.

By understanding the impact of corrosion testing on material selection, businesses can make informed decisions that lead to increased efficiency, cost savings, and improved safety. Eurolab is committed to helping companies navigate this critical aspect of their operations, providing expert guidance and world-class laboratory services to ensure sustainable and efficient business practices.