Determining the effects of crush resistance on battery charge/discharge cycles

Unlocking Battery Performance Determining the Effects of Crush Resistance on Charge/Discharge Cycles

As the world becomes increasingly reliant on rechargeable batteries for energy storage and power supply, manufacturers are under pressure to create products that meet the demands of a rapidly evolving market. One critical factor in determining battery performance is crush resistance the ability of a battery to withstand mechanical stress without compromising its charge/discharge cycles. At Eurolab, our team of experts provides a comprehensive laboratory service to help businesses understand and optimize their products crush resistance, ensuring they meet the stringent requirements of various industries.

What is Crush Resistance?

Crush resistance refers to a batterys ability to maintain its performance under mechanical stress or compression. This can be caused by factors such as transportation damage, accidental drops, or even normal use in harsh environments. In these situations, the battery may experience physical deformation, electrical shorts, or other forms of internal damage that impact its charge/discharge cycles.

Why is Determining Crush Resistance Essential for Businesses?

In todays competitive market, manufacturers need to ensure their products can withstand the rigors of everyday use while maintaining performance and efficiency. By determining the effects of crush resistance on battery charge/discharge cycles, businesses can

Enhance Product Reliability Identify areas where batteries may be vulnerable to mechanical stress, allowing for design improvements that increase overall product reliability.

Optimize Energy Storage Capacity Understand how compression affects a batterys ability to store and release energy, enabling manufacturers to fine-tune their products for maximum efficiency.

Meet Industry Standards Compliance with regulatory requirements, such as those set by the automotive or aerospace industries, can be ensured through comprehensive testing and analysis.

Advantages of Using Eurolabs Laboratory Service

By partnering with Eurolab, businesses can benefit from

Comprehensive Testing Protocols Our experienced team develops tailored test plans to assess crush resistance and its impact on charge/discharge cycles.

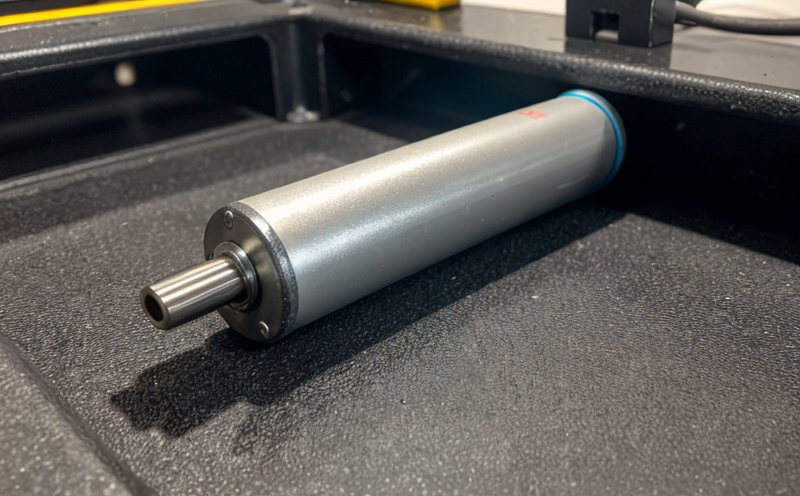

State-of-the-Art Equipment Utilizing advanced instruments and technology, we simulate real-world conditions to accurately evaluate battery performance under mechanical stress.

Detailed Reporting and Analysis Clear, actionable insights are provided in a comprehensive report, outlining areas for improvement and recommendations for product enhancement.

Expert Consultation Our team offers guidance on design optimization, material selection, and testing strategies to ensure products meet industry requirements.

Key Benefits of Determining Crush Resistance

Some of the key advantages of understanding crush resistance include

Improved product reliability and reduced warranty claims

Enhanced energy storage capacity and efficiency

Compliance with regulatory standards and industry certifications

Increased customer satisfaction through durable and long-lasting products

QA Frequently Asked Questions

What types of batteries can be tested for crush resistance?

Our laboratory service is suitable for various battery chemistries, including lithium-ion, lead-acid, nickel-cadmium, and more.

Can Eurolab help me optimize my product design to improve crush resistance?

Yes! Our team offers expert consultation on material selection, design optimization, and testing strategies to ensure your products meet industry requirements.

How long does the laboratory service take, and what is the turnaround time for results?

The duration of our laboratory service varies depending on the complexity of the project and the number of tests required. We provide a dedicated project manager to ensure timely completion and efficient communication.

Can I request custom testing protocols or specific analysis services?

Absolutely! Our team is happy to accommodate bespoke testing requirements and provide tailored analysis to meet your business needs.

Conclusion

In todays fast-paced market, manufacturers must prioritize product reliability, efficiency, and regulatory compliance to stay ahead of the competition. By determining the effects of crush resistance on battery charge/discharge cycles, businesses can unlock their products full potential and drive growth through innovative design and materials development. At Eurolab, our expert team is dedicated to providing comprehensive laboratory services that empower manufacturers to create high-performance batteries that meet industry standards and customer expectations.

Contact us today to learn more about how Eurolabs Determining the effects of crush resistance on battery charge/discharge cycles service can elevate your products performance and stay ahead in a rapidly evolving market.