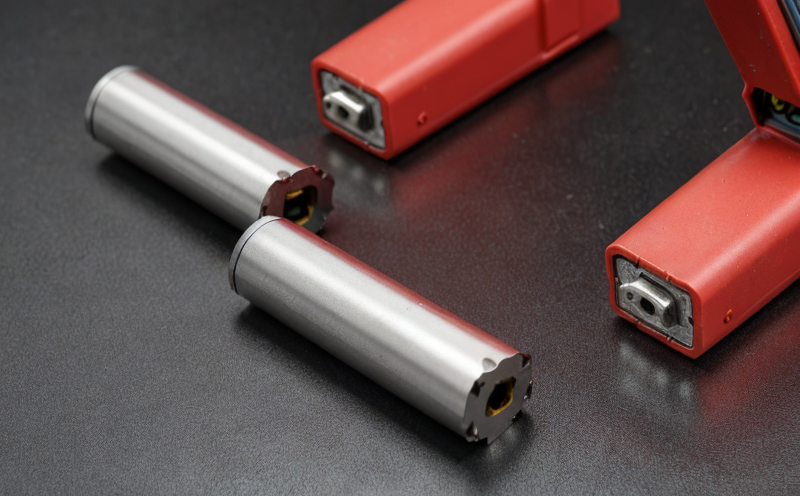

Testing the durability of battery casings against mechanical deformation

The Unyielding Test Ensuring Battery Casing Durability against Mechanical Deformation

In todays fast-paced world of technological advancements, battery-powered devices have become an integral part of our daily lives. From smartphones to electric vehicles, the demand for efficient and reliable batteries has never been higher. However, with increased usage comes the need for robust packaging that can withstand the rigors of everyday life. This is where Testing the durability of battery casings against mechanical deformation comes in a crucial laboratory service provided by Eurolab that ensures your products battery casing can withstand the test of time.

What is Mechanical Deformation?

Mechanical deformation refers to the physical stress or strain caused on an object when subjected to external forces such as impact, compression, or tension. In the context of battery casings, mechanical deformation can manifest in various ways from minor scratches and dents to catastrophic failure resulting in leakage or explosion.

Why is Testing the Durability of Battery Casings against Mechanical Deformation Essential?

The consequences of inadequate testing can be severe

Product recalls due to faulty packaging

Loss of customer trust and reputation damage

Increased maintenance costs for manufacturers

Decreased product lifespan

To mitigate these risks, Eurolab offers a comprehensive laboratory service that puts battery casings through rigorous mechanical deformation tests. Our team of expert engineers uses state-of-the-art equipment to simulate real-world scenarios, ensuring your products meet the highest standards of durability and safety.

Advantages of Using Testing the Durability of Battery Casings against Mechanical Deformation

Here are some key benefits of partnering with Eurolab

Enhanced Product Safety Our tests ensure that battery casings can withstand mechanical stresses without compromising product integrity.

Increased Customer Satisfaction By guaranteeing reliable packaging, youll reduce the likelihood of customer complaints and returns.

Competitive Advantage Durable battery casings set your products apart from competitors, driving sales and revenue growth.

Reduced Maintenance Costs Fewer product failures mean lower maintenance expenses for manufacturers.

Compliance with Industry Standards Our tests align with relevant industry regulations, ensuring you meet stringent safety requirements.

How Does Eurolabs Testing Service Work?

Our process is straightforward

Initial Consultation We work closely with your team to understand your product and testing requirements.

Test Design Our engineers design a customized test plan tailored to your specific needs.

Testing We utilize advanced equipment to simulate real-world mechanical deformation scenarios.

Results Analysis Our expert analysts evaluate the results, providing actionable insights for improvement.

Frequently Asked Questions

Q What types of battery casings can be tested?

A Eurolabs testing service accommodates a wide range of battery casing materials and designs.

Q How long does the testing process take?

A Testing duration varies depending on the complexity of the test, but we aim to deliver results within 2-4 weeks.

Q Can I request custom testing protocols?

A Absolutely. Our team works closely with clients to create tailored testing plans that meet specific requirements.

Q Are Eurolabs test results confidential?

A Yes. We understand the importance of intellectual property protection and maintain confidentiality agreements with all clients.

Conclusion

In an era where product reliability is paramount, Eurolabs Testing the durability of battery casings against mechanical deformation service provides a critical safeguard for manufacturers. By partnering with us, youll not only ensure your products meet the highest standards of safety and performance but also gain a competitive edge in the market. Contact us today to discuss how our laboratory services can help take your business to the next level.

About Eurolab

Eurolab is a leading provider of laboratory testing services, specializing in the development and validation of materials, products, and processes. Our team of expert engineers and scientists utilize state-of-the-art equipment to deliver accurate, reliable results that meet industry standards. With a focus on customer satisfaction and partnership, we strive to become an extension of your companys quality assurance department.