Dielectric Strength Testing for Medical Electronics

The Critical Role of Dielectric Strength Testing for Medical Electronics Ensuring the Safety and Effectiveness of Life-Saving Devices

In the rapidly evolving field of medical electronics, ensuring the reliability and safety of medical devices is paramount. The increasing complexity and miniaturization of these devices have made them more susceptible to electrical failures, which can have serious consequences for patients. Dielectric Strength Testing (DST) for Medical Electronics is a critical laboratory service that plays a vital role in preventing such failures and ensuring the continued effectiveness of life-saving devices.

At Eurolab, we understand the importance of rigorous testing and inspection services for medical electronics manufacturers. Our expert team specializes in providing reliable and accurate DST services to help ensure the safety and performance of your products. In this article, we will delve into the advantages of using Dielectric Strength Testing for Medical Electronics, highlighting its significance in the production process.

What is Dielectric Strength Testing (DST) for Medical Electronics?

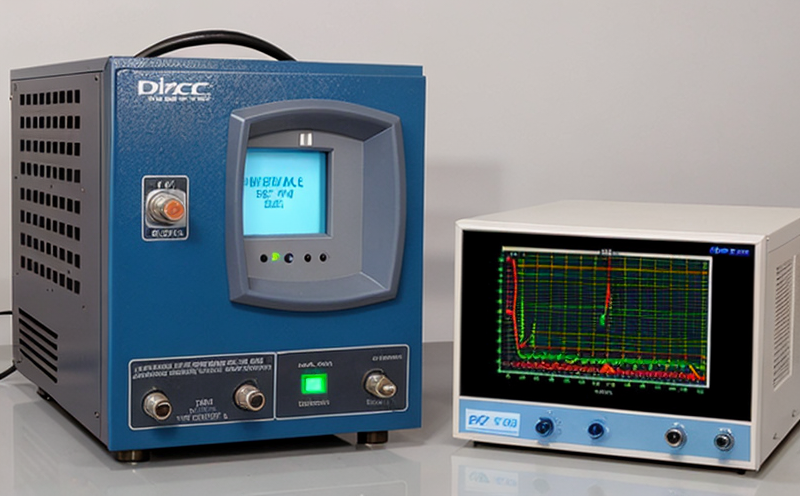

Dielectric Strength Testing, also known as electrical insulation testing or dielectric testing, measures a materials ability to withstand electrical stress without breaking down. In medical electronics, DST is crucial in evaluating the insulating properties of various materials used in devices, such as leads, connectors, and capacitors. The test simulates real-world conditions, subjecting materials to high voltage levels to determine their dielectric strength.

The Importance of Dielectric Strength Testing for Medical Electronics

Dielectric Strength Testing for Medical Electronics is essential for several reasons

Ensures Safety Electrical failures can lead to patient harm or even death. DST helps identify potential issues before they reach the market, ensuring that devices are safe for use.

Prevents Device Failure Malfunctioning medical devices can result in costly recalls and damage to a companys reputation. DST helps manufacturers identify weaknesses and improve device reliability.

Compliance with Regulations Regulatory bodies, such as the FDA and IEC, require medical electronics manufacturers to conduct dielectric strength testing to ensure compliance with safety standards.

Benefits of Dielectric Strength Testing for Medical Electronics

Here are some key benefits of using Dielectric Strength Testing for Medical Electronics

Reliability Enhancement DST helps identify potential weaknesses in materials, allowing manufacturers to improve device reliability and reduce the risk of electrical failures.

Reduced Costs Conducting dielectric strength testing early on can save companies significant costs associated with product recalls, litigation, and reputation damage.

Increased Efficiency Our expert team at Eurolab ensures that DST services are carried out efficiently, minimizing downtime and allowing manufacturers to get products to market faster.

Improved Patient Safety By ensuring the reliability of medical devices, DST contributes to improved patient outcomes and enhanced safety.

Frequently Asked Questions (FAQs)

Here are some frequently asked questions about Dielectric Strength Testing for Medical Electronics

What types of materials can be tested using dielectric strength testing?

What are the advantages of conducting dielectric strength testing at different voltage levels?

How does dielectric strength testing help manufacturers comply with regulatory requirements?

Can dielectric strength testing be conducted on completed medical devices or individual components?

Conclusion

In conclusion, Dielectric Strength Testing for Medical Electronics is a critical laboratory service that plays a vital role in ensuring the safety and effectiveness of life-saving devices. By using DST, manufacturers can improve device reliability, reduce costs, increase efficiency, and enhance patient safety.

At Eurolab, our expert team specializes in providing reliable and accurate dielectric strength testing services to medical electronics manufacturers. Contact us today to learn more about how we can help your business ensure the continued effectiveness of your products.

Sources

International Electrotechnical Commission (IEC) 60664-12007

FDA Guidance for Industry Acceptance Criteria for Insulation Resistance Tests

Medical Device Regulation (MDR) European Parliament and Council Directive 2017/745