Evaluating Insulation Integrity in High-Frequency Circuits

Evaluating Insulation Integrity in High-Frequency Circuits A Critical Service for Businesses

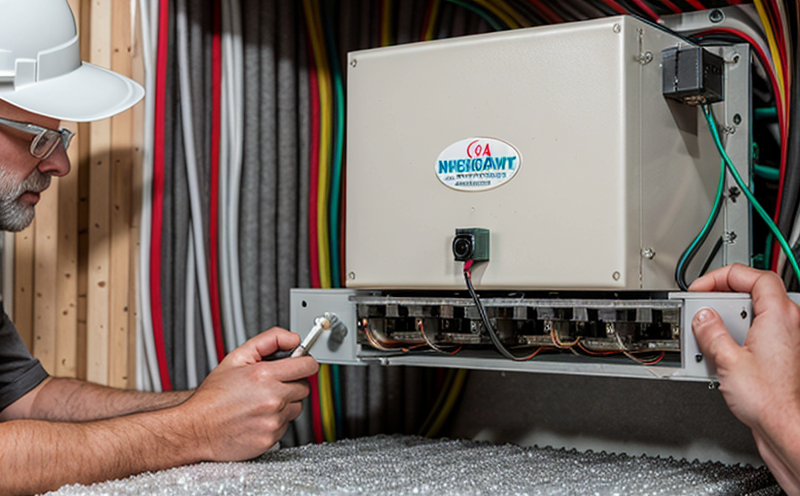

In todays fast-paced and highly competitive business landscape, ensuring the integrity of high-frequency circuits is crucial for maintaining product reliability, efficiency, and performance. As technology continues to evolve at an unprecedented rate, electronic devices are becoming increasingly complex, making it more challenging to guarantee their insulation integrity. This is where Eurolab comes in a leading provider of laboratory services that specializes in evaluating insulation integrity in high-frequency circuits.

In this article, we will delve into the importance of Evaluating Insulation Integrity in High-Frequency Circuits and explore the benefits of utilizing this critical service for businesses. We will also provide a comprehensive breakdown of the advantages of using Eurolabs expert laboratory services to ensure your products meet the highest standards of insulation integrity.

What is Evaluating Insulation Integrity in High-Frequency Circuits?

Evaluating Insulation Integrity in High-Frequency Circuits involves analyzing and testing high-frequency components, such as capacitors, resistors, and inductors, to ensure they can withstand extreme temperatures, humidity, and vibrations without compromising their insulation. This is particularly crucial in high-frequency applications where even minor insulation failures can lead to catastrophic consequences, including product malfunction, reduced lifespan, or even fires.

Why is Evaluating Insulation Integrity in High-Frequency Circuits Essential for Businesses?

The stakes are high when it comes to evaluating insulation integrity in high-frequency circuits. A single failed test can result in significant losses, damage to your brand reputation, and costly redesigns. Here are just a few compelling reasons why businesses should prioritize this critical service

Product Reliability and Performance Evaluating insulation integrity ensures that products meet the required standards for reliability, efficiency, and performance.

Reduced Production Costs By identifying potential insulation failures early on, you can prevent costly redesigns, reworks, and waste.

Compliance with Regulations Ensuring insulation integrity helps businesses comply with industry regulations, such as those related to electromagnetic compatibility (EMC) and safety standards.

Risk Mitigation Evaluating insulation integrity reduces the risk of product recalls, liability claims, and damage to your brand reputation.

Advantages of Using Eurolabs Evaluating Insulation Integrity in High-Frequency Circuits Service

Here are just a few key benefits of utilizing Eurolabs expert laboratory services

Expertise Our team of highly trained engineers and technicians have extensive experience in evaluating insulation integrity in high-frequency circuits.

State-of-the-Art Equipment We utilize the latest technology and equipment to ensure accurate and reliable test results.

Comprehensive Testing Our services cover a wide range of tests, including temperature cycling, humidity testing, and vibration analysis.

Timely Results We provide prompt turnarounds, ensuring that you receive your test results quickly so you can make informed decisions.

Key Benefits of Eurolabs Evaluating Insulation Integrity in High-Frequency Circuits Service

Enhanced Product Reliability Our expert evaluation services ensure that products meet the required standards for insulation integrity.

Improved Efficiency By identifying potential insulation failures early on, we help businesses optimize production processes and reduce waste.

Increased Compliance Eurolabs testing services help businesses comply with industry regulations and standards related to EMC and safety.

Reduced Risk Our evaluations mitigate the risk of product recalls, liability claims, and damage to your brand reputation.

QA Evaluating Insulation Integrity in High-Frequency Circuits

Q1 What types of high-frequency circuits can Eurolab evaluate?

A1 We specialize in evaluating insulation integrity for a wide range of high-frequency components, including capacitors, resistors, and inductors.

Q2 How long does the testing process typically take?

A2 Our turnarounds are prompt, with most tests completed within 3-5 business days.

Q3 What types of test methods do you use for evaluating insulation integrity?

A3 We utilize a range of test methods, including temperature cycling, humidity testing, and vibration analysis.

Q4 How can I ensure my products meet the required standards for insulation integrity?

A4 By partnering with Eurolab, you can trust that our expert evaluations will identify any potential insulation failures, ensuring your products meet the highest standards of insulation integrity.

Conclusion

In todays competitive business landscape, evaluating insulation integrity in high-frequency circuits is no longer a nicety its a necessity. At Eurolab, we understand the critical importance of this service and are committed to providing expert laboratory services that ensure product reliability, efficiency, and performance. Dont risk your brand reputation or bottom line by neglecting this crucial aspect of product development. Contact us today to learn more about how our Evaluating Insulation Integrity in High-Frequency Circuits service can benefit your business.

Learn More About Eurolabs Expert Laboratory Services

At Eurolab, we are dedicated to delivering top-notch laboratory services that meet the evolving needs of businesses in the high-tech industry. From evaluating insulation integrity to testing for electromagnetic compatibility and safety standards, our team is committed to providing expert solutions that enhance product performance, reliability, and efficiency.