The Future of Product Safety Unlocking the Secrets of Drop Test Simulation with Eurolab

In todays fast-paced and competitive business world, product safety is more crucial than ever. With consumers increasingly demanding safer products that meet rigorous standards, companies are under pressure to ensure their goods can withstand even the most extreme conditions. Thats where Drop Test Simulation comes in a cutting-edge laboratory service provided by Eurolab that revolutionizes the way businesses test and validate product durability.

What is Drop Test Simulation?

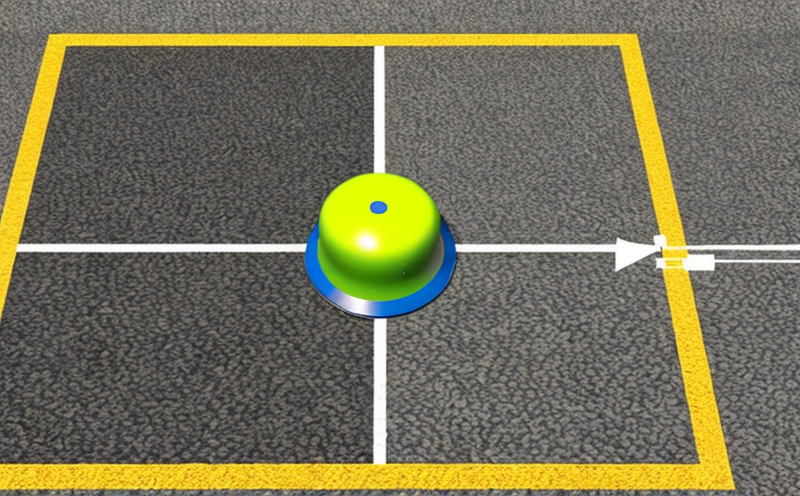

Drop Test Simulation is an innovative and non-destructive testing method that uses advanced computer-aided engineering (CAE) software to simulate the impact of a product being dropped from various heights. This simulation mimics real-world conditions, allowing manufacturers to predict how their products will perform in the event of a drop without the need for physical prototypes.

Why is Drop Test Simulation Essential for Businesses?

In an industry where product recalls and safety failures can have devastating consequences, Drop Test Simulation provides companies with unparalleled peace of mind. By leveraging this technology, businesses can

Save time and money No longer do you need to spend valuable resources on physical prototype testing or reworking products after a failure.

Improve product design With precise simulations, manufacturers can optimize their designs for maximum durability and safety.

Enhance customer trust By demonstrating a commitment to product safety, companies can build stronger relationships with customers and establish a reputation as leaders in the industry.

Key Benefits of Drop Test Simulation

Reduced development time Quickly iterate on design changes without the need for physical prototypes or rework.

Increased accuracy CAE simulations provide more precise results than traditional testing methods, reducing errors and waste.

Cost savings Minimize expenses associated with product failures and recalls.

Improved regulatory compliance Meet stringent safety standards and regulations with confidence.

Enhanced product performance Identify design flaws before they cause problems in the field.

Increased customer satisfaction Deliver safer products that meet or exceed customer expectations.

Competitive edge Differentiate your business by adopting cutting-edge testing methods.

How Drop Test Simulation Works

Eurolabs expert team uses advanced CAE software to create digital models of your product. These simulations are then run through a series of drop tests, each designed to mimic real-world conditions. The results provide valuable insights into the products performance under extreme stress, allowing manufacturers to

Identify design flaws Before they cause problems in the field.

Optimize material selection Choose the most suitable materials for your products.

Refine product geometry Improve overall design and durability.

What Can You Expect from Eurolabs Drop Test Simulation Service?

At Eurolab, we pride ourselves on delivering exceptional service, combined with cutting-edge technology. Our Drop Test Simulation process includes

Expert analysis Our team of experienced engineers will guide you through the simulation process.

Customized simulations Well work closely with you to create tailored simulations that meet your specific needs.

Comprehensive reporting Detailed results and recommendations for improvement.

Frequently Asked Questions

Q What types of products can be tested using Drop Test Simulation?

A Our service is suitable for a wide range of products, including electronics, automotive components, consumer goods, and more.

Q How accurate are the simulations?

A CAE software provides highly accurate results, rivaling those obtained from physical testing methods.

Q Can I use Drop Test Simulation in conjunction with other testing methods?

A Absolutely our service can be combined with traditional testing methods for a comprehensive understanding of product performance.

Conclusion

In todays fast-paced business landscape, companies must prioritize product safety and durability. With Eurolabs innovative Drop Test Simulation service, manufacturers can unlock the secrets to safer products that meet or exceed customer expectations. By leveraging this cutting-edge technology, businesses can reduce development time, save costs, and establish themselves as leaders in their industry.

Get Ahead of the Competition with Eurolabs Drop Test Simulation Service

Dont wait take advantage of our expertise and cutting-edge technology to revolutionize your product testing process. Contact us today to discover how Drop Test Simulation can transform your business and give you a competitive edge in the market.