Drop test simulation for devices with integrated electronics

The Importance of Drop Test Simulation for Devices with Integrated Electronics Protecting Your Business from the Unpredictable

In todays fast-paced world of technology, electronic devices are ubiquitous and an integral part of our daily lives. From smartphones to laptops, tablets, and smartwatches, these gadgets have revolutionized the way we communicate, work, and play. However, with great convenience comes great responsibility. The increasing demand for compact, sleek designs has led to a rise in drop-related damage claims, resulting in costly repairs or even product recalls. This is where Drop test simulation for devices with integrated electronics comes into play a laboratory service that ensures your products are designed to withstand the unpredictable nature of life.

At Eurolab, we offer an innovative and comprehensive solution to help businesses mitigate the risks associated with drop-related damage. Our state-of-the-art testing facilities are equipped with the latest technology to simulate real-world scenarios, providing accurate and reliable results. By partnering with us, you can ensure that your electronic devices meet the highest standards of durability and reliability.

What is Drop Test Simulation?

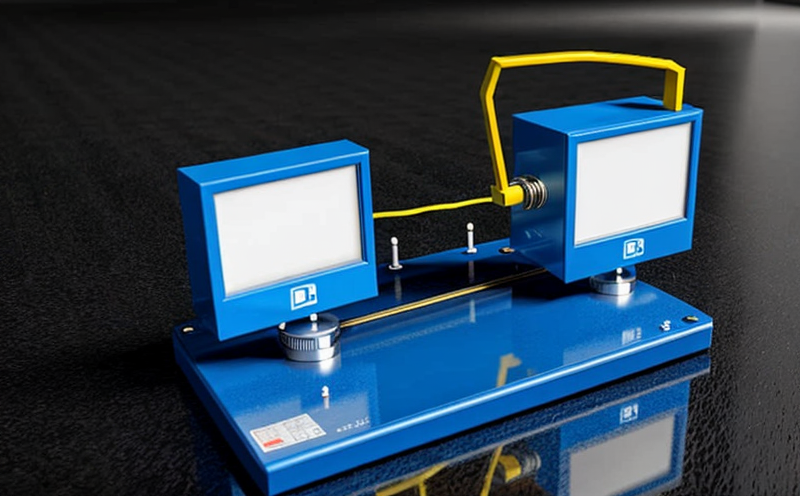

Drop test simulation for devices with integrated electronics involves subjecting products to a series of controlled drops from various heights and angles to determine their ability to withstand impact. This laboratory service replicates real-world scenarios, such as accidental drops, which can cause damage to internal components, including circuit boards, batteries, and other delicate parts.

Why is Drop Test Simulation Essential for Businesses?

The advantages of using drop test simulation for devices with integrated electronics are numerous

Reduces Product Failure Rates By simulating real-world scenarios, you can identify potential design flaws or material weaknesses that may lead to product failure. This enables your team to make necessary adjustments and improvements before mass production.

Minimizes Warranty Claims A drop test simulation helps ensure that your products meet the highest standards of durability, reducing the likelihood of warranty claims related to drop-related damage.

Enhances Brand Reputation By prioritizing product quality and reliability, you can build trust with your customers and establish a reputation for producing robust and long-lasting devices.

Compliance with Industry Standards Drop test simulation is a critical aspect of regulatory compliance. Our testing services ensure that your products meet or exceed industry standards, reducing the risk of recalls and associated costs.

Cost Savings Identifying design flaws or material weaknesses through drop test simulation can save you significant resources in the long run by avoiding costly redesigns, rework, and warranty claims.

Accelerates Time-to-Market By leveraging our expertise and testing capabilities, you can expedite your product development timeline, ensuring that your devices reach the market on schedule.

Key Benefits of Drop Test Simulation for Devices with Integrated Electronics

Our drop test simulation services offer numerous benefits to businesses

Customized Testing Scenarios We work closely with clients to develop tailored testing protocols that mimic real-world scenarios, including drops from various heights and angles.

Accurate and Reliable Results Our state-of-the-art facilities are equipped with the latest technology, ensuring accurate and reliable results that can be trusted by regulatory bodies and industry leaders.

Expert Analysis and Reporting Our team of experienced engineers and technicians provide in-depth analysis and reporting on test results, enabling your team to make data-driven decisions.

Compliance with Regulatory Requirements We ensure that our testing services meet or exceed industry standards, reducing the risk of recalls and associated costs.

QA Frequently Asked Questions about Drop Test Simulation

What types of devices can be tested using drop test simulation?

Our laboratory service is applicable to a wide range of electronic devices, including smartphones, laptops, tablets, smartwatches, and other portable electronics.

How do you determine the testing protocol for each device?

We work closely with clients to develop customized testing protocols that mimic real-world scenarios, taking into account factors such as device size, weight, material composition, and intended use.

What is the typical turnaround time for drop test simulation services?

Our team of experts strives to provide fast and reliable results, typically within a few days or weeks, depending on the complexity of the testing protocol.

Can I witness the testing process in person?

Yes, we welcome clients to observe our testing procedures at your convenience, providing you with firsthand insight into the testing process.

What is the cost associated with drop test simulation services?

Our pricing structure is tailored to meet the unique needs of each client, taking into account factors such as device type, testing protocol, and turnaround time.

Conclusion

In todays competitive landscape, businesses must prioritize product quality and reliability to stay ahead of the curve. Drop test simulation for devices with integrated electronics is an essential laboratory service that helps mitigate the risks associated with drop-related damage. At Eurolab, we offer a comprehensive solution that includes customized testing scenarios, accurate and reliable results, expert analysis and reporting, and compliance with regulatory requirements. By partnering with us, you can ensure that your electronic devices meet the highest standards of durability and reliability, protecting your business from the unpredictable nature of life.

Dont let drop-related damage claims impact your bottom line choose Eurolab for your drop test simulation needs today!