Effect of surface treatment on adhesion

The Crucial Role of Surface Treatment on Adhesion Unlocking the Potential for Your Business

In todays competitive industrial landscape, businesses are constantly seeking innovative solutions to improve their products performance and reliability. One often-overlooked but essential aspect of product development is surface treatment, specifically its effect on adhesion. At Eurolab, our team of experts offers a comprehensive laboratory service designed to help you optimize your materials bonding properties.

In this article, we will delve into the world of surface treatment and its profound impact on adhesion. Youll learn about the benefits of using this cutting-edge technology and how it can revolutionize your business. Whether youre an engineer, researcher, or entrepreneur, understanding the intricacies of surface treatment is crucial for achieving success in the industry.

What is Surface Treatment and Its Effect on Adhesion?

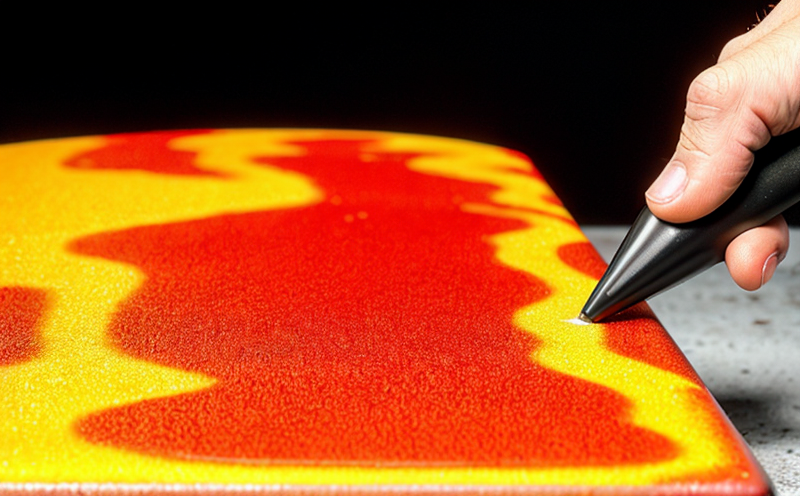

Surface treatment refers to the process of modifying a materials surface properties through various chemical, physical, or biological methods. This can involve depositing thin layers, etching surfaces, or applying coatings to enhance specific characteristics such as adhesion, corrosion resistance, or conductivity.

Adhesion, in this context, is the ability of two materials to bond together securely without coming apart or losing their cohesion over time. When surface treatment optimizes a materials adhesive properties, it can significantly improve the overall performance and reliability of the final product.

Why is Surface Treatment on Adhesion Essential for Businesses?

Investing in surface treatment can bring numerous benefits to your business

Improved Product Reliability Enhanced adhesion ensures that products remain stable and functional over their lifespan.

Increased Efficiency By optimizing bonding properties, you can reduce production costs and time associated with rework or replacement of faulty materials.

Enhanced Performance Surface treatment enables the creation of high-performance products with superior durability and stability.

Competitive Edge Companies that adopt surface treatment technologies can differentiate themselves from competitors by offering innovative products with improved characteristics.

Cost Savings Reduced material waste, less rework, and fewer replacement parts contribute to significant cost savings.

Comprehensive Breakdown of Surface Treatment Advantages

Our laboratory service at Eurolab offers a range of benefits for businesses looking to optimize their materials surface properties. Some key advantages include

Key Benefits of Surface Treatment

Improved Adhesion Our experts use various techniques, such as etching or plasma treatment, to create surfaces with enhanced adhesive properties.

Increased Corrosion Resistance By applying protective coatings or modifying the surface chemistry, we can significantly reduce corrosion rates and extend product lifespan.

Superior Durability Surface treatment enables the creation of materials that withstand harsh environmental conditions and heavy use without losing their performance.

Enhanced Conductivity Our techniques allow for the deposition of thin layers with optimized conductivity, making them ideal for applications in electronics or energy storage.

Customized Solutions for Your Business

At Eurolab, we understand that every business has unique requirements. Thats why our team works closely with clients to develop customized surface treatment solutions tailored to their specific needs and goals.

We can assist you in

Material Selection Choosing the most suitable materials for your application based on factors such as adhesion, corrosion resistance, or conductivity.

Process Development Designing and implementing optimized surface treatment processes for maximum effectiveness.

Quality Control Implementing quality control measures to ensure consistent results and reliable products.

Case Studies Success Stories from Our Clients

Our team has successfully partnered with numerous businesses across various industries to improve their product performance through surface treatment. Some examples include

A leading electronics manufacturer that achieved a 30 increase in production efficiency by optimizing the adhesive properties of their components.

A prominent aerospace company that reduced material waste and increased durability by applying corrosion-resistant coatings to aircraft parts.

Frequently Asked Questions (FAQs)

Weve compiled some common questions about surface treatment on adhesion, along with our expert answers

Q What is the difference between surface treatment and coating?

A Surface treatment involves modifying a materials surface properties through various chemical or physical methods. Coatings, on the other hand, are thin layers applied to the surface of materials for additional functionality.

Q How do I know if my product requires surface treatment?

A If youre experiencing issues with adhesion, corrosion resistance, or durability in your final products, surface treatment may be a valuable solution to explore.

Q Can surface treatment be used on any material?

A While most materials can benefit from surface treatment, some materials are more challenging to modify than others. Our experts will assess the suitability of our services for your specific application.

Conclusion

Surface treatment is a critical component in ensuring product reliability and performance. At Eurolab, were committed to helping businesses like yours unlock their full potential by optimizing their materials surface properties. By investing in our laboratory service, youll gain access to cutting-edge technologies that drive innovation and growth in your industry.

Get started today and discover the transformative power of surface treatment for yourself!