Evaluation of adhesive strength on composite materials

Unlocking the Secrets of Adhesion Evaluation of Adhesive Strength on Composite Materials

In todays fast-paced and competitive business landscape, ensuring the reliability and durability of materials is crucial for success. Composite materials, in particular, have become an integral part of various industries, including aerospace, automotive, construction, and more. However, their adhesive strength plays a vital role in determining their overall performance and lifespan.

At Eurolab, our team of experts offers a specialized laboratory service that helps businesses evaluate the adhesive strength of composite materials. This critical analysis is essential for understanding how well two or more materials stick together, which can make all the difference between a products success and failure.

The Importance of Adhesive Strength on Composite Materials

Adhesive strength refers to the ability of a material to withstand forces that try to separate it from another material to which it is bonded. When composite materials are subjected to various stresses, such as temperature fluctuations, mechanical loads, or environmental exposure, their adhesive strength can significantly impact their performance.

Poor adhesive strength can lead to catastrophic consequences, including

Reduced lifespan and increased maintenance costs

Decreased product efficiency and effectiveness

Increased risk of accidents and injuries

Damage to brand reputation and loss of customer trust

On the other hand, a strong adhesive bond between composite materials can ensure

Enhanced durability and resistance to wear and tear

Improved performance under various operating conditions

Increased safety and reduced risk of accidents

Boosted confidence in product quality and reliability

Advantages of Using Evaluation of Adhesive Strength on Composite Materials

Our laboratory service at Eurolab offers numerous benefits for businesses that rely on composite materials. Some of the key advantages include

Improved Product Performance By evaluating adhesive strength, you can optimize your products performance under various operating conditions, ensuring they meet or exceed industry standards.

Increased Safety and Reliability Our tests help identify potential weaknesses in adhesion, allowing you to take corrective actions and minimize risks associated with material failure.

Cost Savings Identifying and addressing adhesive strength issues early on can save you significant costs in the long run by reducing maintenance needs, minimizing product recalls, and preventing accidents.

Enhanced Brand Reputation By investing in the evaluation of adhesive strength, you demonstrate your commitment to quality and safety, which can foster trust with customers and stakeholders.

Some additional benefits of our laboratory service include

Compliance with Industry Regulations Our tests ensure that your products meet or exceed industry standards, reducing the risk of non-compliance and associated fines.

Competitive Advantage By understanding the adhesive strength of your composite materials, you can develop more reliable and durable products, setting yourself apart from competitors.

Increased Innovation With our expert analysis, youll gain valuable insights into material behavior under various conditions, driving innovation and improvement in product design.

How Our Laboratory Service Works

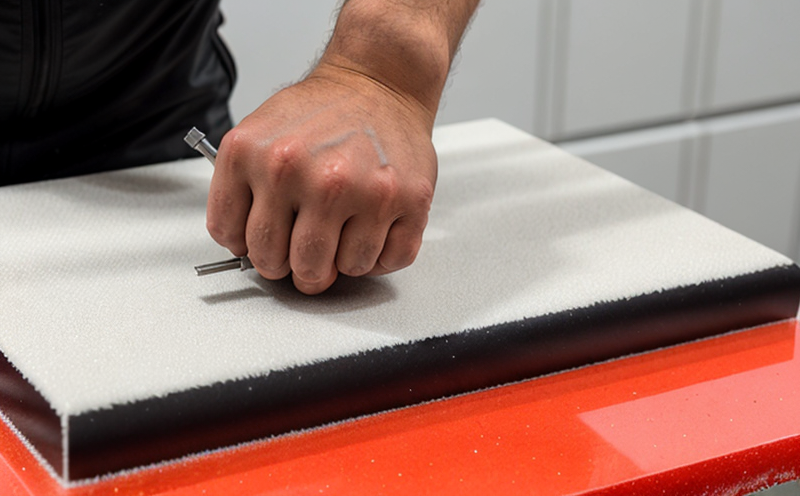

At Eurolab, we employ state-of-the-art equipment and techniques to evaluate the adhesive strength of composite materials. Our comprehensive testing protocols include

Mechanical Testing Tensile, shear, and peel tests assess material adhesion under various loads.

Environmental Exposure Materials are subjected to environmental conditions, such as temperature, humidity, and UV radiation, to simulate real-world scenarios.

Analytical Techniques Advanced methods like FTIR, XPS, and SEM provide detailed insights into material properties and bonding mechanisms.

QA Section

We understand that you may have questions about our laboratory service. Here are some frequently asked questions (FAQs) with answers

Q What types of composite materials can be tested?

A Our laboratory is equipped to test a wide range of composite materials, including polymers, metals, ceramics, and more.

Q How do I prepare my samples for testing?

A Please follow our guidelines for sample preparation, which include specific handling, storage, and transportation instructions.

Q What are the common reasons for poor adhesive strength in composite materials?

A Common issues include incorrect material selection, inadequate surface preparation, insufficient curing times, or exposure to harsh environmental conditions.

Q How long does a typical testing cycle take?

A Our testing protocols vary depending on the specific requirements of each project. However, most tests can be completed within 1-5 working days.

Conclusion

Evaluating adhesive strength is crucial for businesses that rely on composite materials. By understanding how well these materials stick together, you can optimize their performance, ensure safety and reliability, and reduce costs associated with maintenance and potential accidents.

At Eurolab, were dedicated to providing expert analysis and testing services that help you make informed decisions about your products. Our team of experienced professionals is committed to delivering high-quality results and supporting your businesss growth and success. Contact us today to learn more about our laboratory service and how it can benefit your organization.