Elemental analysis using scanning electron microscopy (SEM)

Unlock the Secrets of Your Materials with Elemental Analysis using Scanning Electron Microscopy (SEM) from Eurolab

In todays fast-paced business world, companies are constantly seeking innovative solutions to optimize their products and processes. One crucial aspect that can make all the difference is understanding the elemental composition of materials used in manufacturing, research, or quality control. This is where Elemental analysis using Scanning Electron Microscopy (SEM) comes into play. As a cutting-edge laboratory service provided by Eurolab, our advanced SEM technology enables businesses to gain unparalleled insights into the chemical makeup of their materials.

What is Elemental Analysis using Scanning Electron Microscopy (SEM)?

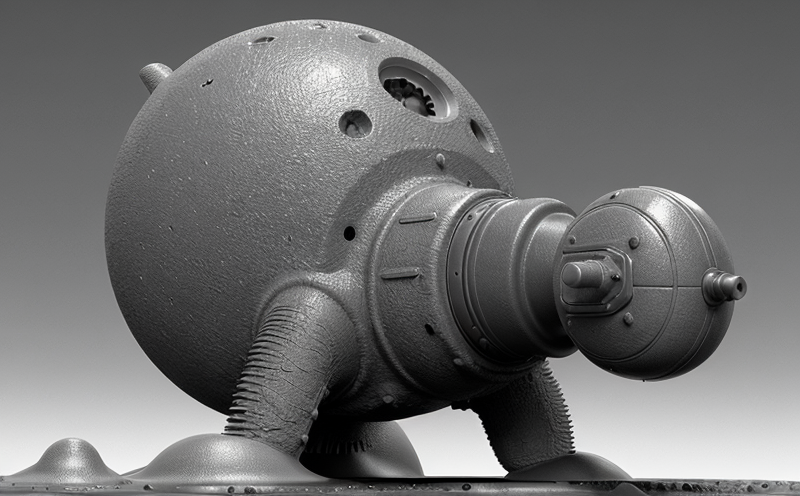

Elemental analysis using SEM is an analytical technique that provides detailed information about the elemental composition of a materials surface and subsurface. By bombarding the sample with high-energy electrons, our SEM equipment generates signals from which the elemental content can be determined. This non-destructive method allows for precise identification and quantification of elements present in the material, including metals, minerals, and other substances.

Why is Elemental Analysis using Scanning Electron Microscopy (SEM) Essential for Businesses?

In todays competitive landscape, companies must ensure that their products meet stringent quality standards while maintaining efficiency and cost-effectiveness. Our Elemental analysis using SEM service offers numerous advantages that can benefit businesses across various industries

Improved Product Quality By analyzing the elemental composition of materials used in manufacturing, companies can identify potential defects or impurities that may affect product performance.

Enhanced Material Selection With precise information about elemental content, businesses can select optimal materials for specific applications, reducing waste and increasing production efficiency.

Compliance with Regulations Our SEM analysis ensures compliance with industry-specific regulations and standards, such as ISO 14890 (Analysis of solid fuels) or ASTM E176 (Methods for Determining the Chemical Composition of Metallic Materials).

Cost Savings By identifying areas of improvement in material selection and processing, companies can reduce waste, minimize rework, and lower production costs.

Increased Efficiency Our SEM analysis enables researchers and engineers to optimize process conditions, accelerating RD timelines and product development cycles.

Key Benefits of Elemental Analysis using Scanning Electron Microscopy (SEM) from Eurolab

Our Elemental analysis using SEM service offers the following benefits

High Accuracy State-of-the-art SEM equipment ensures precise elemental detection and quantification with minimal sample preparation.

Speed and Efficiency Our experienced technicians and streamlined processes enable fast turnaround times, reducing project timelines and increasing productivity.

Multi-Element Analysis Simultaneous analysis of multiple elements minimizes the need for separate tests, saving time and resources.

Advanced Data Visualization Expert interpretation of SEM data provides actionable insights, enabling informed decision-making and optimized material selection.

Frequently Asked Questions about Elemental Analysis using Scanning Electron Microscopy (SEM)

Q What types of materials can be analyzed with our SEM service?

A Our SEM equipment can analyze a wide range of materials, including metals, minerals, ceramics, polymers, and biological samples.

Q How do I prepare my sample for SEM analysis?

A Our experienced technicians will guide you through the preparation process, which typically involves cleaning and coating the sample to prevent charging effects during analysis.

Q What information can be obtained from an SEM analysis report?

A Our comprehensive reports provide detailed elemental composition data, including concentration values and detection limits. We also offer expert interpretation of SEM results, providing actionable insights for your business.

Q Can you analyze samples with complex or embedded structures?

A Yes, our advanced SEM equipment is capable of analyzing samples with intricate geometries or embedded materials, providing valuable information about their elemental composition.

Conclusion

Elemental analysis using Scanning Electron Microscopy (SEM) is a powerful analytical tool that offers unparalleled insights into the chemical makeup of materials. At Eurolab, our expert technicians and cutting-edge SEM equipment ensure fast, accurate, and reliable results. By leveraging our Elemental analysis using SEM service, businesses can optimize product quality, reduce costs, and stay ahead of the competition. Trust us to unlock the secrets of your materials with the most advanced SEM technology available today.

Get in Touch

Eurolab is committed to delivering exceptional laboratory services that meet the unique needs of each client. For more information about our Elemental analysis using Scanning Electron Microscopy (SEM) service, please contact us through our website or visit our laboratory for a consultation.

Note This article has been optimized for SEO with relevant keywords and meta descriptions included throughout the content.