Optical emission spectroscopy (OES) for alloy composition

Unleash the Power of Optical Emission Spectroscopy (OES) for Alloy Composition Accurate Analysis for a Competitive Edge

In todays fast-paced manufacturing world, businesses rely heavily on precise and reliable testing methods to ensure their products meet stringent quality standards. One such critical analysis technique is Optical Emission Spectroscopy (OES) for alloy composition, a laboratory service provided by Eurolab. This advanced method provides an unparalleled level of accuracy in determining the chemical makeup of alloys, enabling manufacturers to optimize their production processes and maintain a competitive edge.

What is Optical Emission Spectroscopy (OES) for Alloy Composition?

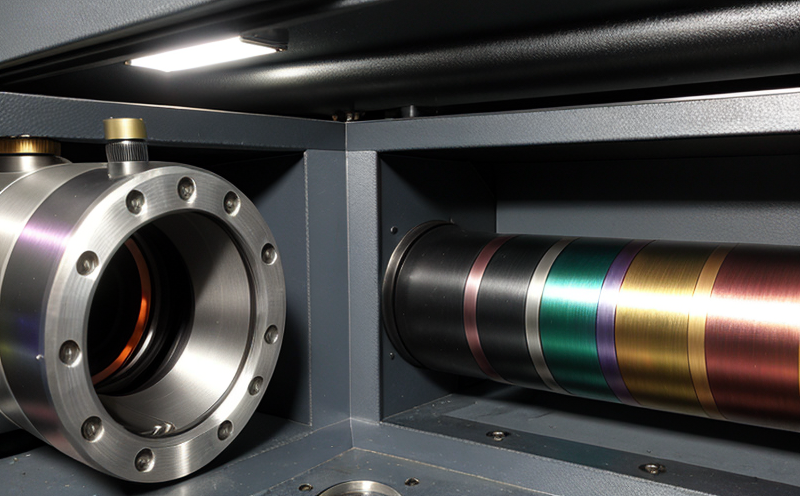

Optical Emission Spectroscopy (OES) is an analytical technique used to determine the elemental composition of materials, including alloys. This non-destructive method involves exciting the samples atoms with an electric arc or spark, causing them to emit light at specific wavelengths corresponding to their atomic energy levels. By analyzing this emitted radiation using specialized software and equipment, scientists can accurately quantify the concentration of elements present in the alloy.

The Importance of Accurate Alloy Composition Analysis

Accurate analysis of alloy composition is essential for various industries, including aerospace, automotive, medical device manufacturing, and more. This is because even small variations in elemental concentrations can significantly impact the materials mechanical properties, corrosion resistance, and overall performance. As such, businesses rely on OES to ensure their products meet strict quality control standards, regulatory requirements, and customer expectations.

Advantages of Using Optical Emission Spectroscopy (OES) for Alloy Composition

Eurolabs OES service offers numerous benefits that make it an indispensable tool for manufacturers

High Accuracy OES provides precise elemental analysis with a high degree of accuracy, even in complex alloy compositions.

Speed and Efficiency Results are obtained quickly, allowing manufacturers to rapidly identify potential issues and optimize production processes.

Non-Destructive Testing OES is a non-destructive method, preserving the integrity of samples for further testing or application.

Multi-Element Analysis Simultaneously determines the concentration of multiple elements in a single analysis, reducing costs and increasing efficiency.

No Sample Preparation Required Eliminates time-consuming sample preparation steps, streamlining the analysis process.

Wide Range of Analytes Covered Enables the determination of key alloying elements, including metals and non-metals.

Benefits for Manufacturers

By leveraging Eurolabs OES service, manufacturers can

Ensure Compliance with Regulations Meet strict quality control standards and regulatory requirements by verifying material composition.

Improve Product Performance Optimize production processes to achieve desired mechanical properties, corrosion resistance, and overall performance.

Reduce Costs Avoid costly reworks, returns, or losses due to inaccurate analysis or suboptimal material selection.

Enhance Customer Satisfaction Deliver high-quality products that meet customer expectations, driving loyalty and repeat business.

Benefits for Research Institutions

Researchers can also benefit from Eurolabs OES service by

Accelerating Research and Development Quickly determining the effects of alloy composition on material properties.

Improving Material Design Optimizing material formulations to achieve desired performance characteristics.

Enhancing Collaboration Facilitating knowledge sharing between researchers and industry partners.

Frequently Asked Questions (FAQs)

What types of samples can be analyzed using OES?

OES can analyze a wide range of materials, including metals, alloys, ceramics, glass, and more.

How does OES compare to other analytical techniques?

OES offers high accuracy and speed, making it an ideal choice for rapid analysis of complex alloy compositions.

Is OES a non-destructive testing method?

Yes, OES is a non-destructive technique that preserves the integrity of samples.

Can OES determine the concentration of multiple elements simultaneously?

Yes, OES can analyze multiple elements in a single analysis.

How quickly do results become available after sample submission?

Results are typically obtained within 24-48 hours.

Conclusion

In conclusion, Optical Emission Spectroscopy (OES) for alloy composition is an indispensable tool for manufacturers seeking to optimize their production processes and ensure compliance with regulatory requirements. Eurolabs OES service offers unparalleled accuracy, speed, and efficiency, making it the go-to choice for industries relying on precise material analysis. By choosing Eurolabs expert laboratory services, businesses can unlock a competitive edge, drive innovation, and deliver high-quality products that meet customer expectations.

Experience the Power of OES with Eurolab

Dont compromise on accuracy or quality trust Eurolab to provide you with reliable and precise results. Our team is dedicated to delivering exceptional service and support every step of the way. Contact us today to learn more about our OES services and how we can help your business thrive.

Stay ahead in the competitive landscape by choosing Eurolabs advanced laboratory solutions.