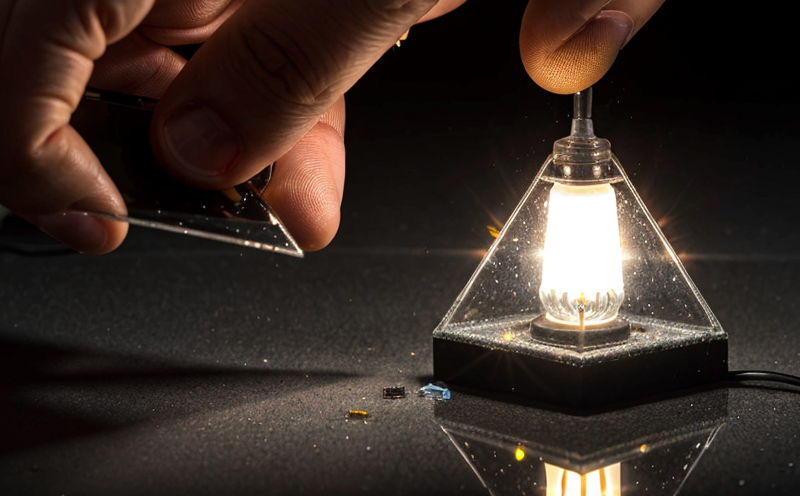

Ensuring that the lighting device's glass does not shatter into dangerous fragments when impacted.

The Importance of Impact Resistance in Lighting Devices Ensuring Safety with Eurolabs Laboratory Service

As businesses strive to maintain a safe and compliant work environment, one often-overlooked aspect is the impact resistance of lighting devices. The glass components of these devices can shatter into dangerous fragments when impacted, posing a significant risk to employees, visitors, and equipment. In this article, we will delve into the world of ensuring that the lighting devices glass does not shatter into hazardous fragments when impacted, a critical laboratory service provided by Eurolab.

What is Ensuring that the Lighting Devices Glass Does Not Shatter into Dangerous Fragments When Impacted?

Ensuring that the lighting devices glass does not shatter into dangerous fragments when impacted refers to the process of testing and evaluating the resistance of glass components in lighting devices to withstand various types of impacts, including drops, bumps, and other forms of physical stress. This laboratory service is essential for businesses seeking to ensure compliance with safety regulations and standards, such as those set by OSHA (Occupational Safety and Health Administration) and IEC (International Electrotechnical Commission).

Advantages of Using Ensuring that the Lighting Devices Glass Does Not Shatter into Dangerous Fragments When Impacted

The advantages of using Eurolabs laboratory service to ensure impact resistance in lighting devices are numerous

Enhanced Safety By testing and evaluating the glass components of lighting devices, businesses can identify potential risks and take corrective action to prevent accidents.

Compliance with Regulations Ensuring that lighting devices meet safety standards is crucial for compliance with regulatory requirements. Eurolabs laboratory service helps businesses avoid costly fines and reputational damage.

Increased Product Reliability By identifying and addressing weaknesses in glass components, businesses can improve the overall reliability of their products and reduce the risk of product failure.

Reduced Liability In the event of an accident caused by a faulty lighting device, businesses that have undergone Eurolabs laboratory service can demonstrate due diligence and reduce liability.

Key Benefits of Ensuring Impact Resistance in Lighting Devices

The key benefits of ensuring impact resistance in lighting devices are

Reduced Risk of Accidents By evaluating the glass components of lighting devices, businesses can identify potential risks and take corrective action to prevent accidents.

Improved Product Quality Eurolabs laboratory service helps businesses ensure that their products meet high standards of quality and reliability.

Cost Savings Identifying and addressing weaknesses in glass components can help businesses reduce costs associated with product recalls, repairs, and replacements.

Increased Customer Trust By prioritizing safety and compliance, businesses can build trust with customers and improve their reputation.

QA Frequently Asked Questions about Ensuring Impact Resistance in Lighting Devices

Q What types of lighting devices require impact testing?

A All types of lighting devices that contain glass components, including but not limited to LED lights, fluorescent lights, and incandescent bulbs.

Q How does Eurolabs laboratory service ensure compliance with regulatory requirements?

A Our expert technicians use state-of-the-art equipment and follow established protocols to evaluate the impact resistance of glass components in lighting devices, ensuring that they meet or exceed relevant safety standards.

Q What are the typical costs associated with Eurolabs laboratory service?

A Costs vary depending on the scope and complexity of the testing required. Our team will work closely with clients to provide a customized quote for their specific needs.

Q Can I perform impact testing in-house, or do I need to rely on an external laboratory service like Eurolab?

A While some businesses may choose to perform impact testing in-house, relying on an external laboratory service like Eurolab offers several benefits, including objectivity, expertise, and compliance with regulatory requirements.

Conclusion

Ensuring that the lighting devices glass does not shatter into dangerous fragments when impacted is a critical aspect of maintaining a safe and compliant work environment. By partnering with Eurolab for their laboratory service, businesses can identify potential risks, improve product quality, reduce liability, and increase customer trust. Dont compromise on safety choose Eurolab for your impact resistance testing needs.

Get Started Today

Contact us to discuss how Eurolabs laboratory service can help your business ensure the safety and compliance of its lighting devices. Together, we can work towards a safer and more reliable product.

-

Testing lighting devices for resistance to glass breakage under various conditions.

-

Evaluating the durability and toughness of glass used in lighting devices, such as bulbs and fixtures.

-

Testing for breakage due to mechanical shock, impact, or stress.

-

Simulating scenarios where lighting devices are dropped or subjected to external forces.

-

Assessing the performance of glass components, such as lampshades or covers, when exposed to impacts.

-

Testing for cracks or fractures in glass as a result of thermal shock or rapid temperature changes.

-

Verifying compliance with safety standards for lighting devices with glass components (e.g., UL 8750).

-

Testing the fragility of glass used in outdoor lighting devices, especially for street lamps and floodlights.

-

Assessing the structural integrity of glass under extreme weather conditions such as hail or heavy winds.

-

Testing for breakage or deformation of glass components in safety-critical lighting systems, such as emergency lights.

-

Evaluating the safety of glass in lighting devices to ensure it does not pose a hazard if broken.

-

Testing the resistance of glass in light bulbs to vibration, handling, and transportation.

-

Verifying that lighting systems with glass components are safe for use in public areas where breakage could be dangerous.

-

Assessing the impact of glass breakage on the overall functionality of the lighting system.

-

Testing for the sharpness of broken glass edges to reduce the risk of injury.

-

Verifying the integrity of glass in sealed lighting systems, preventing moisture or dirt ingress.

-

Assessing how glass breakage affects the light output or performance of the device.

-

Testing for glass breakage resistance in energy-efficient lighting systems like LEDs.

-

Verifying the robustness of glass components in decorative or architectural lighting.

-

Evaluating the use of alternative materials like plastic or polycarbonate in place of glass for breakage resistance.

-

Testing for ease of glass replacement or repair in lighting fixtures.