Testing for breakage due to mechanical shock, impact, or stress.

Testing for Breakage Due to Mechanical Shock, Impact, or Stress Ensuring Product Safety and Reliability

In todays fast-paced business environment, companies are constantly seeking ways to improve product performance, reduce costs, and minimize liabilities. One crucial aspect of ensuring product safety and reliability is testing for breakage due to mechanical shock, impact, or stress. This laboratory service, provided by Eurolab, helps businesses identify potential weaknesses in their products, preventing costly failures and associated risks.

What is Testing for Breakage Due to Mechanical Shock, Impact, or Stress?

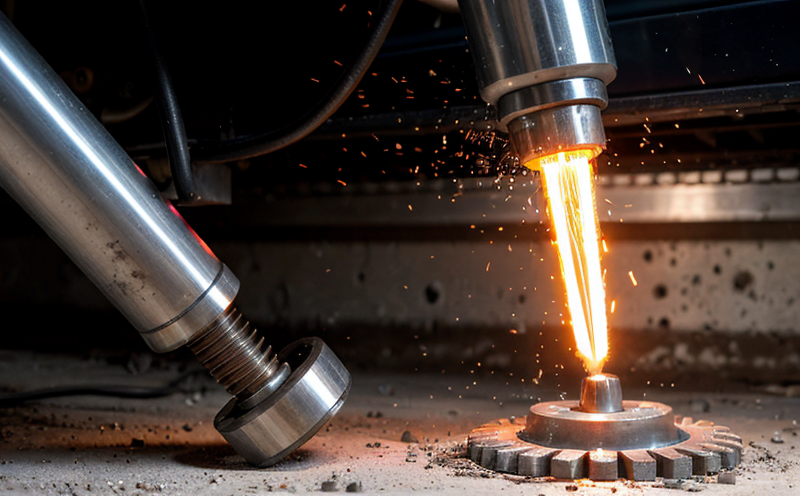

Mechanical shock, impact, or stress testing involves subjecting a product to controlled loads or forces to assess its ability to withstand mechanical stress without breaking or failing. This type of testing is essential in various industries, including aerospace, automotive, construction, and consumer goods, where products are exposed to harsh environments and unpredictable forces.

Why is Testing for Breakage Due to Mechanical Shock, Impact, or Stress Essential?

Testing for breakage due to mechanical shock, impact, or stress offers numerous benefits for businesses. Some of the key advantages include

Advantages of Using Eurolabs Testing Services

Improved Product Safety By identifying potential weaknesses in products, companies can ensure they meet regulatory requirements and minimize the risk of product failures.

Enhanced Reliability Mechanical shock, impact, or stress testing helps businesses understand how their products will perform under real-world conditions, reducing the likelihood of unexpected failures.

Cost Savings Identifying and addressing potential issues early on saves companies from costly product recalls, repairs, and replacements.

Compliance with Regulations Testing for breakage due to mechanical shock, impact, or stress helps businesses comply with industry standards and regulations, such as those set by the International Organization for Standardization (ISO).

Increased Customer Confidence By demonstrating a commitment to product safety and reliability, companies can build trust with their customers and establish a reputation for excellence.

Competitive Advantage Companies that prioritize testing for breakage due to mechanical shock, impact, or stress can differentiate themselves from competitors and gain a competitive edge in the market.

How Does Eurolabs Testing Service Work?

At Eurolab, our team of experienced engineers and technicians use state-of-the-art equipment to conduct comprehensive mechanical shock, impact, or stress testing. Our service includes

Customized Test Plans We work with clients to develop tailored test plans that meet their specific needs and requirements.

Advanced Testing Equipment Our lab is equipped with the latest technology, including drop towers, impact hammers, and tensile testers.

Expert Analysis Our team of engineers provides detailed analysis and interpretation of test results, highlighting areas for improvement.

Frequently Asked Questions (FAQs)

What types of products can be tested for breakage due to mechanical shock, impact, or stress?

Any product that is subject to mechanical stress can be tested, including but not limited to electronics, automotive components, aircraft parts, construction materials, and packaging.

How do I know if my product needs testing for breakage due to mechanical shock, impact, or stress?

If your product is exposed to harsh environments, subjected to repetitive impacts, or has a history of failures, it may benefit from mechanical shock, impact, or stress testing.

What are the typical test methods used in Eurolabs service?

We use a range of test methods, including drop testing, impact testing, tensile testing, and fatigue testing, depending on the specific requirements of the product and client.

Can I request customized testing protocols?

Yes, our team works with clients to develop tailored test plans that meet their specific needs and requirements.

How long does a typical testing project take?

The duration of a testing project varies depending on the complexity of the tests, the type of equipment used, and the number of samples required. Our team will provide a detailed timeline for each project.

What kind of reporting and documentation can I expect from Eurolabs service?

We provide comprehensive test reports, including detailed analysis and recommendations for product improvement. All reports are formatted in accordance with industry standards and client requirements.

Conclusion

Testing for breakage due to mechanical shock, impact, or stress is an essential aspect of ensuring product safety and reliability. By partnering with Eurolab, businesses can identify potential weaknesses in their products, prevent costly failures, and establish a reputation for excellence. With our state-of-the-art equipment, expert analysis, and customized testing services, we help companies like yours navigate the complex world of mechanical shock, impact, or stress testing. Contact us today to learn more about how Eurolabs laboratory service can benefit your business.