Evaluating cooling performance of robots used in high-speed operations

Evaluating Cooling Performance of Robots in High-Speed Operations A Crucial Service for Businesses

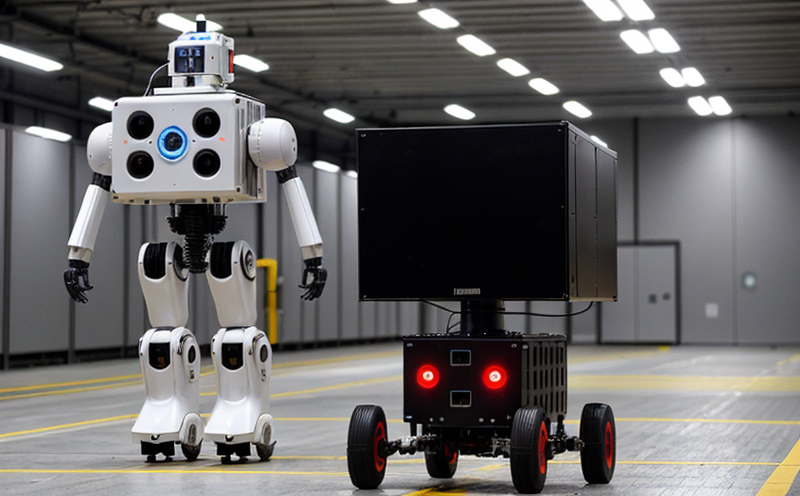

In todays fast-paced industrial landscape, robots have become an indispensable part of high-speed operations. From manufacturing and logistics to healthcare and research, robots are used to streamline processes, increase efficiency, and enhance productivity. However, with increasing demands on these machines comes the need for effective cooling systems to prevent overheating and ensure optimal performance.

At Eurolab, we understand the significance of evaluating the cooling performance of robots in high-speed operations. Our laboratory service is designed to help businesses identify potential cooling-related issues, improve system efficiency, and reduce downtime. In this article, well delve into the importance of evaluating cooling performance, its benefits, and why our comprehensive testing services can make a significant difference for your business.

The Importance of Evaluating Cooling Performance

Cooling systems play a vital role in maintaining the optimal operating temperature of robots used in high-speed operations. When these machines overheat, they can experience reduced performance, increased energy consumption, and even premature failure. The consequences can be far-reaching

Reduced productivity Overheated robots slow down or shut down, leading to decreased production rates.

Increased costs Energy consumption rises, and maintenance expenses grow due to frequent repairs and replacements.

Equipment damage Heat stress can cause irreparable harm to sensitive components, resulting in costly replacements.

Advantages of Evaluating Cooling Performance

By evaluating the cooling performance of your robots, youll be able to

Identify Potential Issues Detect overheating problems early on, preventing equipment damage and reducing downtime.

Improve System Efficiency Optimize cooling systems for maximum performance, reducing energy consumption and costs.

Enhance Reliability Ensure that your robots operate at optimal temperatures, minimizing the risk of premature failure.

Increase Productivity Maximize production rates by maintaining consistent machine performance.

Reduce Maintenance Costs Minimize maintenance expenses by identifying and addressing cooling-related issues promptly.

Our comprehensive testing services include

Thermal imaging analysis to detect temperature hotspots

Air flow and pressure testing to ensure adequate cooling airflow

Vibration analysis to identify potential bearing or motor issues

System calibration and performance optimization

How Our Service Works

At Eurolab, we take a meticulous approach to evaluating the cooling performance of your robots. Heres an overview of our process

Initial Consultation We discuss your specific requirements and provide guidance on the testing procedures.

Sampling and Preparation We collect representative samples from your robot systems for analysis.

Thermal Imaging Analysis Our experts conduct thermal imaging scans to detect temperature hotspots and assess overall system performance.

Data Analysis We analyze the collected data, identifying areas of improvement and potential cooling-related issues.

Reporting and Recommendations We provide a comprehensive report outlining our findings and recommendations for optimization.

QA Section

Q What types of robots are eligible for evaluation?

A Our service is applicable to a wide range of robots used in high-speed operations, including industrial robotic arms, CNC machines, conveyor systems, and more.

Q How long does the testing process take?

A The duration of our testing services varies depending on the complexity of your system. Typically, results are available within 2-4 weeks.

Q What kind of data can I expect from the testing report?

A Our comprehensive report includes detailed thermal imaging analysis, airflow and pressure test results, vibration analysis data, and recommendations for optimization.

Q Will you provide maintenance or repair services if issues are identified?

A While we can recommend specific maintenance or repair actions, our primary focus is on providing a thorough evaluation and optimization plan to improve system performance.

Conclusion

Evaluating the cooling performance of robots used in high-speed operations is no longer an optional service its a necessity for businesses seeking to optimize productivity, reduce costs, and prevent equipment damage. At Eurolab, we offer a comprehensive laboratory service designed to help you

Identify potential cooling-related issues

Improve system efficiency

Enhance reliability

Increase productivity

Reduce maintenance costs

Dont let overheating robots hinder your business performance. Contact us today to schedule an evaluation and take the first step towards optimized high-speed operations.

Additional Information

Our team of experts is dedicated to providing top-notch laboratory services tailored to meet your unique needs. For more information on our Evaluating cooling performance of robots used in high-speed operations service, visit our website or contact us directly.

We look forward to helping you optimize your robot systems and achieve unparalleled efficiency and productivity.