Evaluating heat resistance of motors and actuators in robotic applications

Evaluating Heat Resistance of Motors and Actuators in Robotic Applications Unlocking Efficiency and Reliability

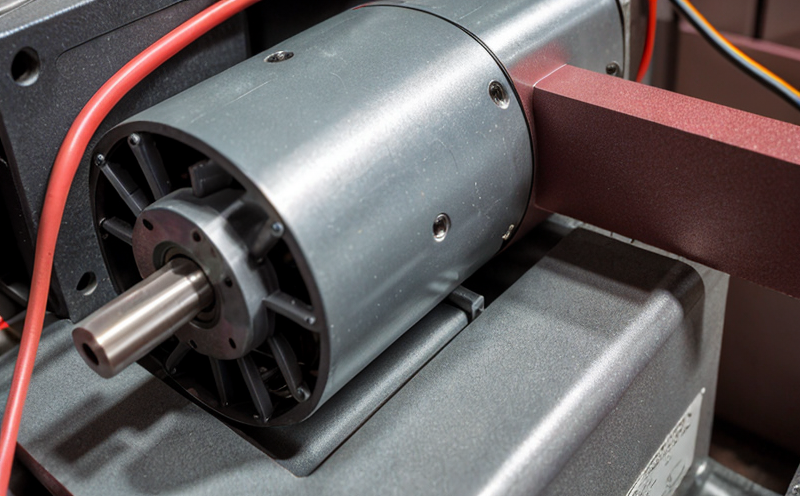

In the rapidly evolving landscape of robotics and automation, businesses are constantly seeking innovative ways to improve the performance and reliability of their robotic systems. One crucial aspect that often goes unnoticed is the evaluation of heat resistance in motors and actuators. These components are the backbone of any robotic system, responsible for translating electrical energy into mechanical motion. However, excessive heat generation can lead to premature wear, reduced lifespan, and even catastrophic failures.

At Eurolab, we specialize in providing a comprehensive laboratory service that helps businesses evaluate the heat resistance of their motors and actuators. Our expert team employs state-of-the-art equipment and techniques to assess the thermal performance of these critical components, ensuring that your robotic systems operate at peak efficiency and reliability.

Why is Evaluating Heat Resistance Essential for Businesses?

In todays competitive market, businesses can no longer afford to compromise on the performance and reliability of their robotic systems. Excessive heat generation can lead to

Reduced lifespan Heat stress can cause motors and actuators to fail prematurely, resulting in costly repairs and replacements.

Decreased efficiency Inefficient cooling mechanisms can lead to reduced motor performance, decreased productivity, and increased energy consumption.

Increased maintenance costs Frequent repairs and maintenance can become a significant burden on businesses, eating into their bottom line.

By evaluating the heat resistance of motors and actuators, businesses can

Optimize system design Identify areas where thermal issues can be mitigated, improving overall system efficiency and reliability.

Reduce downtime Minimize the likelihood of motor or actuator failures, ensuring continuous operation and maximum productivity.

Increase lifespan Extend the lifespan of critical components, reducing maintenance costs and minimizing waste.

Benefits of Evaluating Heat Resistance at Eurolab

Our comprehensive laboratory service offers a range of benefits that can transform your robotic systems

Accurate thermal analysis Our expert team employs advanced techniques to measure heat dissipation rates, temperature profiles, and other critical parameters.

Customized testing protocols We tailor our testing procedures to meet the specific needs of your motors and actuators, ensuring accurate and relevant results.

Data-driven decision-making Receive actionable insights and recommendations to optimize system design, improve performance, and reduce costs.

Compliance with industry standards Our laboratory is equipped to test components in accordance with international standards (e.g., IEC 60034-2-14), ensuring that your products meet regulatory requirements.

How Does Eurolab Evaluate Heat Resistance?

Our evaluation process involves a combination of theoretical analysis and practical testing, including

Thermal modeling Employing advanced software to simulate heat transfer within motors and actuators.

Experimental testing Conducting experiments using specialized equipment (e.g., thermal cameras, thermocouples) to measure temperature profiles, heat dissipation rates, and other critical parameters.

Material analysis Investigating the thermal properties of materials used in motor and actuator design.

QA Evaluating Heat Resistance at Eurolab

Q What types of motors and actuators can be evaluated for heat resistance?

A Our laboratory services cater to a wide range of motors and actuators, including electric motors, hydraulic actuators, pneumatic actuators, and more.

Q How long does the evaluation process typically take?

A The duration of our testing procedures varies depending on the complexity of the project. However, we strive to provide fast turnaround times without compromising on quality or accuracy.

Q What kind of data can I expect from the evaluation process?

A Our expert team provides comprehensive reports detailing thermal performance, temperature profiles, heat dissipation rates, and other critical parameters. We also offer actionable recommendations for improving system design and reducing costs.

Q How do I ensure compliance with industry standards?

A Our laboratory is equipped to test components in accordance with international standards (e.g., IEC 60034-2-14). We will work closely with you to develop a customized testing protocol that meets your specific needs and regulatory requirements.

In conclusion, evaluating the heat resistance of motors and actuators is a crucial step in optimizing robotic system performance and reliability. At Eurolab, we specialize in providing comprehensive laboratory services that help businesses unlock efficiency, reduce costs, and minimize downtime. By partnering with us, you can ensure that your robotic systems operate at peak performance, driving productivity and competitiveness in todays fast-paced market.

Contact us to learn more about our evaluation services and how they can benefit your business.