Evaluating the effect of repeated motion on cable fatigue in robots

Evaluating the Effect of Repeated Motion on Cable Fatigue in Robots A Crucial Service for Businesses

In todays fast-paced industrial landscape, robotics has become an indispensable tool for businesses across various sectors. From manufacturing to healthcare, robots have revolutionized the way we work and live. However, as with any machinery, robots are not immune to wear and tear. One critical aspect that often gets overlooked is cable fatigue in robots, which can lead to equipment failure, downtime, and significant financial losses.

At Eurolab, our team of expert engineers understands the importance of maintaining the reliability and efficiency of industrial robots. Thats why we offer a specialized laboratory service Evaluating the effect of repeated motion on cable fatigue in robots. In this article, we will delve into the significance of this service, its benefits, and answer frequently asked questions to help businesses make informed decisions.

The Importance of Cable Fatigue Evaluation

Cable fatigue is a common issue that affects robotic systems, particularly those with moving parts or cables. When cables are subjected to repetitive motion, they can suffer from wear and tear, leading to degradation over time. This can cause a range of problems, including

Reduced system performance

Increased downtime for maintenance and repair

Higher energy consumption

Decreased lifespan of equipment

In extreme cases, cable fatigue can lead to catastrophic failures, resulting in costly damage and loss of productivity.

Advantages of Evaluating the Effect of Repeated Motion on Cable Fatigue

Our laboratory service offers numerous benefits that can help businesses optimize their robotic systems. Some of the key advantages include

Improved System Reliability By evaluating cable fatigue, we identify potential issues before they become major problems, ensuring your robot operates at peak performance.

Increased Uptime Regular maintenance and repairs reduce downtime, allowing you to maximize production and meet demanding schedules.

Energy Efficiency Optimized systems consume less energy, resulting in lower operational costs and a reduced carbon footprint.

Extended Equipment Lifespan Proactive cable fatigue evaluation extends the lifespan of your equipment, reducing the need for premature replacements.

Reduced Maintenance Costs Identifying and addressing potential issues early on saves you money on costly repairs and replacement parts.

Here are some additional benefits in bullet points

Enhanced Safety By detecting potential hazards before they occur, we help prevent accidents and ensure a safer working environment.

Compliance with Industry Regulations Our evaluation service ensures your equipment meets industry standards and regulations, minimizing the risk of fines or penalties.

Competitive Advantage By investing in our laboratory service, you demonstrate your commitment to quality and reliability, setting your business apart from competitors.

How Our Laboratory Service Works

Our Evaluating the effect of repeated motion on cable fatigue in robots service is a comprehensive process that involves

System Evaluation We assess your robots design, materials, and operating conditions to identify potential risks.

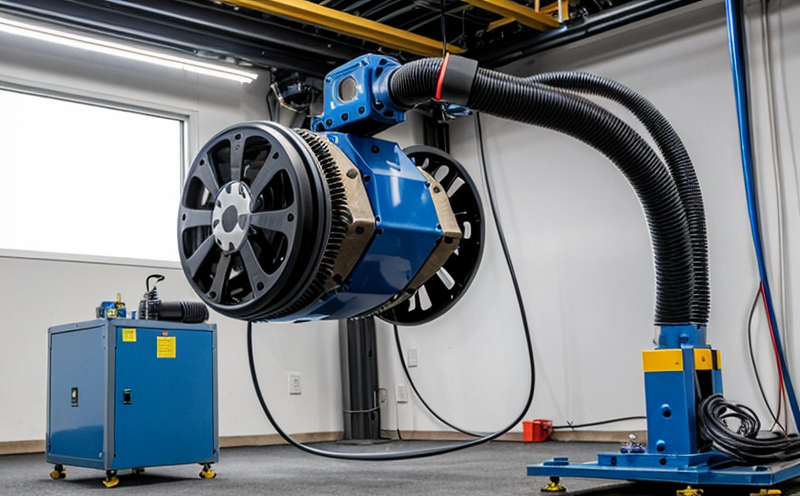

Cable Fatigue Testing Our laboratory equipment simulates real-world scenarios to test the cables resistance to repetitive motion.

Data Analysis We analyze the results, providing a detailed report on cable fatigue levels and recommendations for improvement.

Implementation of Recommendations Our team works with you to implement the necessary modifications or repairs to prevent future issues.

Frequently Asked Questions

Q What types of robots are affected by cable fatigue?

A Any robot with moving parts or cables is susceptible to cable fatigue, including those used in manufacturing, healthcare, and logistics.

Q How often should I have my robots cables evaluated for fatigue?

A We recommend regular evaluations (every 6-12 months) depending on usage, environmental conditions, and equipment age.

Q Can I perform the evaluation myself or do I need to hire a professional?

A While some manufacturers provide guidelines, our expert engineers offer a more comprehensive and accurate assessment of your robots cable fatigue levels.

Q What is the cost of this laboratory service?

A Our pricing is based on the complexity of the test, equipment costs, and time required for evaluation. We will provide you with a custom quote after discussing your specific needs.

Conclusion

In conclusion, Evaluating the effect of repeated motion on cable fatigue in robots is a crucial service that can help businesses prevent costly downtime, reduce energy consumption, and extend equipment lifespan. By partnering with Eurolab, you can ensure your robotic systems operate at peak performance while minimizing risks associated with cable fatigue.

Dont wait until its too late schedule an evaluation today to safeguard your businesss success in the industrial landscape. Our expert engineers are ready to help you optimize your robots and stay ahead of the competition.

Get Started with Eurolab

Take the first step towards optimizing your robotic systems by contacting us for a consultation. Together, we can ensure your equipment operates safely, efficiently, and at peak performance.