Testing cable insulation integrity in high-temperature robotic environments

Testing Cable Insulation Integrity in High-Temperature Robotic Environments A Crucial Service for Businesses

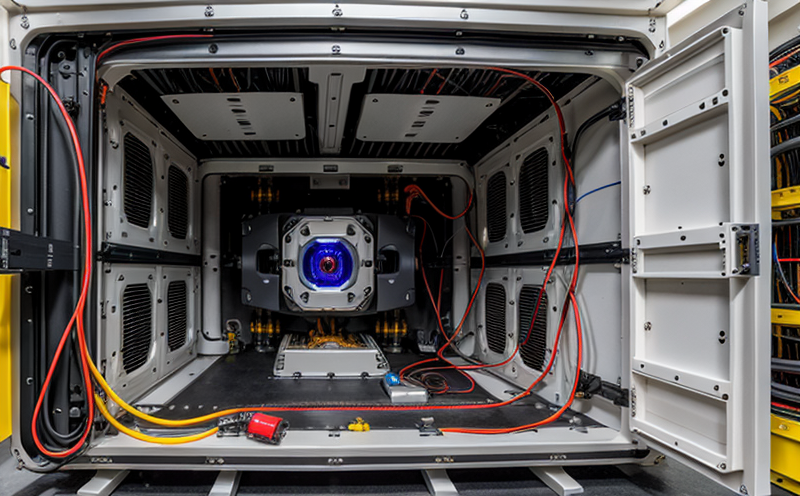

In todays fast-paced industrial landscape, robotic systems have become an integral part of various sectors, including manufacturing, logistics, and healthcare. These robots are designed to operate efficiently and safely in diverse environments, from extreme temperatures to hazardous conditions. However, the high-temperature settings can pose a significant challenge to their functionality, particularly when it comes to cable insulation integrity.

At Eurolab, we understand the importance of reliable robotic systems and offer a specialized laboratory service testing cable insulation integrity in high-temperature robotic environments. This critical assessment helps businesses ensure that their robotic equipment operates optimally, reducing downtime, improving productivity, and minimizing potential safety risks.

The Importance of Cable Insulation Integrity

Cable insulation plays a vital role in maintaining the overall performance and reliability of robotic systems. In high-temperature environments, cables can degrade quickly, leading to electrical discharges, overheating, or even catastrophic failures. When cable insulation integrity is compromised, it can result in

Reduced equipment lifespan

Increased maintenance costs

Downtime and productivity losses

Potential safety hazards for personnel

Advantages of Testing Cable Insulation Integrity

Eurolabs testing service provides numerous benefits to businesses operating high-temperature robotic environments. Some key advantages include

Predictive Maintenance Regular testing enables you to identify potential issues before they occur, reducing the likelihood of unexpected downtime and minimizing maintenance costs.

Improved Safety By detecting compromised cable insulation, you can take proactive measures to prevent electrical discharges, overheating, or other safety risks that may lead to injuries or fatalities.

Enhanced Productivity Reliable robotic systems mean reduced downtime, allowing your business to maintain optimal production levels and meet customer demands.

Extended Equipment Lifespan Regular testing helps extend the lifespan of your equipment by identifying potential issues early on, reducing the need for premature replacements.

Compliance with Industry Standards Our service ensures that your robotic systems meet industry standards, reducing the risk of non-compliance penalties or reputational damage.

How Eurolabs Testing Service Works

At Eurolab, we employ state-of-the-art equipment and expert technicians to conduct thorough testing of cable insulation integrity in high-temperature environments. Our process involves

Equipment Preparation We carefully prepare your robotic systems for testing, ensuring that all necessary equipment is available.

Testing Protocols Our experienced technicians follow standardized testing protocols to assess the cable insulations condition and identify any potential issues.

Data Analysis We analyze test data to provide you with a comprehensive report detailing the results of each test, including recommendations for maintenance or replacement.

Reporting and Recommendations A detailed report is provided to your organization, outlining the findings and recommending necessary actions to maintain optimal equipment performance.

QA Frequently Asked Questions

Q What types of robotic systems can be tested?

A We can test a wide range of robotic systems, including industrial robots, collaborative robots (cobots), and autonomous mobile robots.

Q How often should cable insulation integrity be tested?

A Testing frequency depends on various factors, such as equipment usage, environmental conditions, and industry standards. Our experts will advise you on the optimal testing schedule for your organization.

Q What are the benefits of partnering with Eurolab for this service?

A By choosing Eurolabs laboratory service, you can ensure that your robotic systems meet industry standards, reduce downtime, improve productivity, and minimize safety risks while also benefiting from our expertise and state-of-the-art equipment.

Q Is the testing process destructive or non-destructive?

A Our testing protocols are designed to be non-destructive, ensuring that your equipment remains intact after testing.

Conclusion

In todays fast-paced industrial landscape, it is essential for businesses operating high-temperature robotic environments to prioritize cable insulation integrity. Eurolabs specialized laboratory service provides a comprehensive solution for testing cable insulation integrity in these challenging settings. By partnering with us, you can ensure the reliability and performance of your robotic systems, reducing downtime, improving productivity, and minimizing potential safety risks.

If your business relies on high-temperature robotic environments, dont compromise on equipment performance or safety choose Eurolabs laboratory service to guarantee optimal results.

Additional Resources

For more information about Eurolabs testing services, including pricing and testing protocols, please visit our website at Eurolab Website URL.