Evaluating the effectiveness of moisture barrier films in blister packs and vials

The Critical Role of Evaluating Moisture Barrier Films in Blister Packs and Vials Enhancing Product Stability and Shelf Life

In the pharmaceutical industry, ensuring the stability and shelf life of products is paramount. One critical aspect that contributes to this goal is the evaluation of moisture barrier films in blister packs and vials. At Eurolab, our team of experts provides a comprehensive laboratory service that assesses the effectiveness of these films in maintaining product integrity.

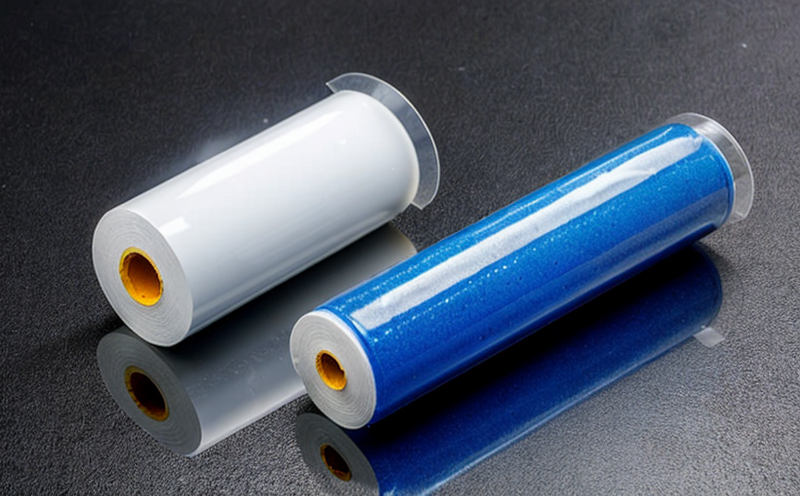

Moisture barrier films are an essential component in the packaging of pharmaceutical products, particularly for sensitive items like medications, vaccines, and medical devices. These films prevent moisture from entering the package, thereby protecting the contents from degradation, oxidation, or microbial contamination. However, not all moisture barrier films perform equally well under various conditions.

Why is Evaluating Moisture Barrier Films Crucial?

The consequences of using inadequate moisture barrier films can be severe. Products may become ineffective, lose potency, or even pose a health risk to consumers. Moreover, recalls and product failures can result in significant financial losses for businesses. Conversely, investing in an evaluation service ensures that products are packaged with the right materials, guaranteeing their stability and efficacy.

Benefits of Evaluating Moisture Barrier Films in Blister Packs and Vials

The advantages of our laboratory service at Eurolab are numerous

Guaranteed Product Stability Our evaluations ensure that moisture barrier films effectively protect contents from environmental factors.

Extended Shelf Life By verifying the effectiveness of these films, businesses can confidently extend shelf life without compromising product quality.

Reduced Risk of Contamination Our service helps prevent microbial contamination and degradation caused by excessive moisture.

Compliance with Regulations Evaluations ensure that products meet regulatory requirements for packaging and storage conditions.

Cost Savings By identifying inadequate films early on, businesses can avoid costly product failures and recalls.

Key Benefits of Eurolabs Evaluation Service

Customized Testing Protocols We tailor our evaluations to suit your specific needs and product requirements.

Expert Analysis and Interpretation Our team provides in-depth analysis and recommendations for improving moisture barrier film performance.

Accelerated Testing We offer accelerated testing protocols to simulate real-world conditions, ensuring that products meet desired specifications.

Frequently Asked Questions (FAQs)

Q What types of products can be evaluated?

A Our service is suitable for a wide range of pharmaceutical products, including medications, vaccines, and medical devices.

Q How long does the evaluation process take?

A The duration varies depending on the specific requirements and testing protocols used. We work closely with clients to ensure timely results.

Q What are the benefits of using accelerated testing?

A Accelerated testing simulates real-world conditions, allowing businesses to evaluate product performance under extreme scenarios.

Q Can Eurolab provide recommendations for improving moisture barrier film performance?

A Yes, our team provides expert analysis and recommendations for optimizing film performance based on test results.

Conclusion

Evaluating the effectiveness of moisture barrier films in blister packs and vials is a critical step in ensuring product stability and shelf life. At Eurolab, we offer a comprehensive laboratory service that assesses these films under various conditions. By investing in our evaluation service, businesses can guarantee their products meet desired specifications, reduce the risk of contamination, and extend shelf life without compromising quality.