Testing the durability of moisture barriers after exposure to extreme environmental conditions

Testing the Durability of Moisture Barriers after Exposure to Extreme Environmental Conditions A Crucial Service for Businesses

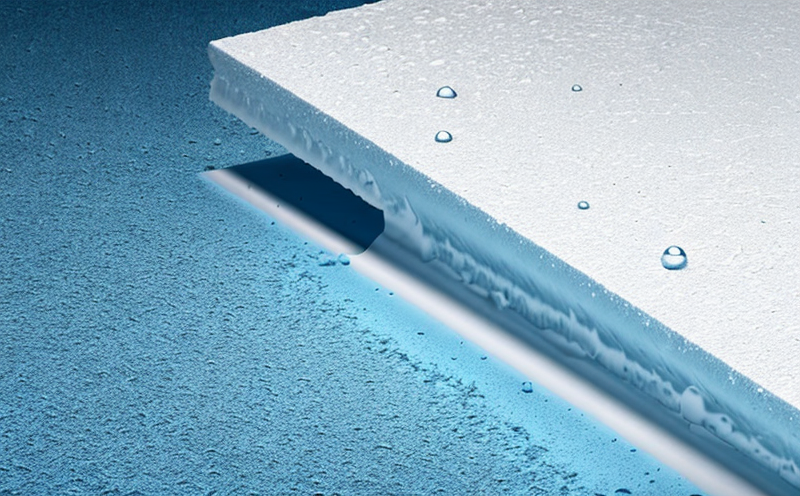

In todays fast-paced and ever-evolving construction industry, building materials are subject to extreme environmental conditions that can compromise their integrity. Moisture barriers, in particular, play a critical role in protecting buildings from water damage, mold growth, and other issues that can arise from exposure to weathering agents such as rain, snow, sun, wind, and temperature fluctuations. However, these products must withstand various environmental conditions without degrading or losing their effectiveness.

What is Testing the Durability of Moisture Barriers after Exposure to Extreme Environmental Conditions?

Testing the durability of moisture barriers after exposure to extreme environmental conditions involves subjecting these materials to rigorous testing protocols that simulate various weather conditions. This process helps assess a products performance and identify potential weaknesses, ensuring it can withstand the harsh realities of real-world applications.

Why is Testing the Durability of Moisture Barriers after Exposure to Extreme Environmental Conditions Essential for Businesses?

With increasing scrutiny on building durability and sustainability, businesses must ensure that their products meet stringent standards. Conducting thorough testing and validation helps companies

Reduce liability By identifying potential weaknesses in their products, companies can minimize risks associated with water damage, mold growth, and other issues.

Improve product performance Testing enables manufacturers to refine their products, enhancing overall durability and effectiveness.

Enhance brand reputation Demonstrating a commitment to quality and safety through rigorous testing can boost a companys credibility and customer trust.

Key Benefits of Eurolabs Testing Service

Eurolab offers an extensive range of testing services designed to evaluate the performance of moisture barriers under various environmental conditions. Our team utilizes state-of-the-art equipment and expert knowledge to provide accurate, reliable results that help companies

Assess product longevity Understand how well your products will perform over time.

Evaluate resistance to weathering agents Determine their ability to withstand exposure to rain, snow, sun, wind, and temperature fluctuations.

Identify potential weaknesses Pinpoint areas for improvement to enhance overall product performance.

Eurolabs Advanced Testing Capabilities

Our team of experts employs a range of testing methods to assess moisture barrier durability

Accelerated Weathering Tests Simulate various environmental conditions using controlled climate chambers, UV light sources, and spray nozzles.

Water Penetration Tests Evaluate the products ability to withstand water exposure through immersion, spray, or flood tests.

Physical Properties Testing Assess material properties such as tensile strength, adhesion, and flexibility.

Comprehensive QA Section

Q What types of moisture barriers can be tested?

A Our team can test various types of moisture barriers, including membranes, coatings, and films.

Q How do you simulate extreme environmental conditions?

A We utilize state-of-the-art equipment to create controlled climate chambers that mimic real-world weather patterns.

Q What kind of data can I expect from the testing process?

A Our team provides detailed reports outlining test results, including performance metrics and recommendations for improvement.

Q Can you customize your testing services to meet our specific needs?

A Yes, we offer tailored testing programs designed to address unique product requirements and industry standards.

Conclusion

In conclusion, Testing the durability of moisture barriers after exposure to extreme environmental conditions is a vital service that helps businesses ensure their products meet stringent standards. By partnering with Eurolab, companies can gain valuable insights into their products performance and make informed decisions to enhance overall quality and safety.

Dont compromise on product integrity trust Eurolabs expertise in testing moisture barrier durability. Contact us today to learn more about our services and how we can help you succeed in the construction industry.