Evaluating the purity of materials used in implantable devices

The Unyielding Pursuit of Purity Evaluating Materials for Implantable Devices

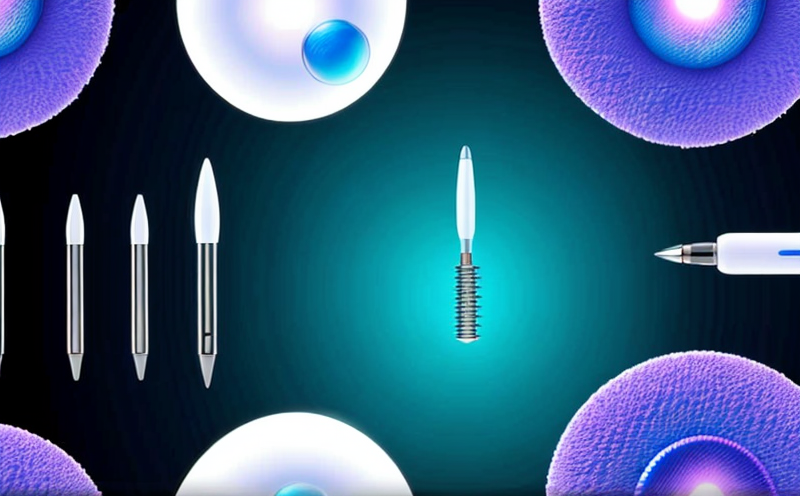

In the realm of medical technology, implantable devices have revolutionized patient care by offering innovative solutions to complex health issues. From pacemakers and cochlear implants to artificial joints and dental implants, these devices have improved the lives of millions worldwide. However, their effectiveness and safety depend on one critical factor the purity of materials used in their construction.

As a leading provider of laboratory services, Eurolab understands the significance of material purity in implantable devices. Our team of experts is dedicated to helping businesses like yours evaluate the integrity of your materials, ensuring that your products meet the highest standards of quality and safety.

What is Evaluating the Purity of Materials Used in Implantable Devices?

Evaluating the purity of materials used in implantable devices involves a series of tests designed to assess the chemical composition, physical properties, and biocompatibility of raw materials. This process ensures that only the highest-quality materials are used in the production of medical implants, minimizing the risk of adverse reactions or device failure.

At Eurolab, our laboratory services cater to the specific needs of businesses involved in the development and manufacturing of implantable devices. Our team utilizes cutting-edge technology and industry-leading expertise to provide comprehensive evaluations that guarantee your materials meet the most stringent standards.

Why is Evaluating the Purity of Materials Used in Implantable Devices Essential for Businesses?

The consequences of using impure or low-quality materials in implantable devices can be catastrophic, resulting in

Device failure Poor material quality can lead to mechanical failure, compromising patient safety and device effectiveness.

Adverse reactions Contaminated or reactive materials can cause serious health issues, including inflammation, tissue damage, or even life-threatening conditions.

Regulatory compliance issues Failure to adhere to industry standards for material purity can result in costly recalls, fines, or even business closure.

To mitigate these risks and ensure the highest level of quality, businesses must prioritize evaluating the purity of materials used in implantable devices. By doing so, you can

Advantages of Using Evaluating the Purity of Materials Used in Implantable Devices

Improved patient safety By ensuring the purity of your materials, you minimize the risk of adverse reactions and device failure.

Enhanced product performance High-quality materials guarantee consistent results, reducing the likelihood of mechanical issues or system failures.

Increased regulatory compliance Our evaluations ensure that your products meet or exceed industry standards for material purity, reducing the risk of costly recalls or fines.

Reduced liability By demonstrating a commitment to quality and safety, you minimize the risk of lawsuits and reputational damage.

Key Benefits of Eurolabs Evaluating the Purity of Materials Used in Implantable Devices

Comprehensive testing Our team conducts a thorough evaluation of your materials, including chemical composition, physical properties, and biocompatibility.

Industry-leading expertise Our experts have extensive experience in evaluating material purity for implantable devices.

State-of-the-art technology We utilize cutting-edge equipment to ensure accurate and reliable results.

Customized solutions Our team tailors our services to meet the specific needs of your business.

QA Evaluating the Purity of Materials Used in Implantable Devices

Q What types of materials are evaluated for purity?

A We evaluate a wide range of materials, including metals (e.g., titanium, stainless steel), polymers, ceramics, and composites.

Q How do I know which tests to conduct on my materials?

A Our team will work with you to determine the most relevant tests based on your specific needs and product requirements.

Q What is the turnaround time for evaluations?

A Our standard turnaround time is 2-4 weeks, depending on the complexity of the evaluation and the availability of our equipment.

Q Can Eurolab provide certification or documentation for compliance purposes?

A Yes, we can provide certification or documentation to support your regulatory compliance needs.

Conclusion

In the world of implantable devices, material purity is paramount. At Eurolab, we understand the critical importance of evaluating materials to ensure the highest standards of quality and safety. By partnering with us, you can

Reduce the risk of adverse reactions and device failure

Enhance product performance and consistency

Increase regulatory compliance and reduce liability

Benefit from industry-leading expertise and state-of-the-art technology

Dont compromise on material purity. Trust Eurolab to ensure your implantable devices meet the most stringent standards. Contact us today to learn more about our laboratory services and how we can help you achieve unparalleled quality and safety in your products.

Additional Resources

Learn more about our laboratory services

Download a case study or whitepaper on material purity evaluations

Explore our teams expertise and credentials

At Eurolab, we are committed to helping businesses like yours navigate the complex landscape of implantable device development. With our comprehensive testing and evaluation services, you can rest assured that your products meet the highest standards of quality and safety.