Material composition analysis for medical device packaging materials

The Crucial Role of Material Composition Analysis for Medical Device Packaging Materials Ensuring Compliance and Quality

In the fast-paced world of medical device manufacturing, packaging materials play a critical role in ensuring the safety and efficacy of life-saving products. However, with the ever-evolving regulatory landscape and increasing scrutiny on material safety, manufacturers must be proactive in verifying the composition of their packaging materials to avoid costly recalls, reputational damage, and legal repercussions.

At Eurolab, we understand the significance of Material Composition Analysis (MCA) for medical device packaging materials and offer a comprehensive laboratory service to support your business needs. In this article, well delve into the importance of MCA, its benefits, and how our expert team can help you navigate the complex regulatory environment.

What is Material Composition Analysis for Medical Device Packaging Materials?

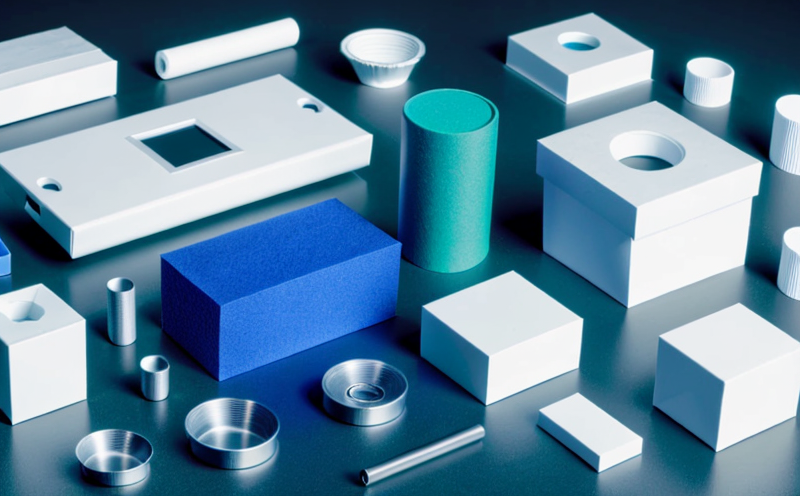

Material Composition Analysis involves the identification and quantification of the chemical composition of packaging materials used in medical device manufacturing. This laboratory service helps manufacturers determine the presence and concentration of various elements, including heavy metals, plastics, adhesives, and other additives that may affect product performance or pose a risk to patient safety.

Why is Material Composition Analysis Essential for Businesses?

In todays highly regulated industry, MCA has become an indispensable tool for medical device manufacturers. Here are some compelling reasons why

Compliance with Regulatory Requirements Medical devices are subject to strict regulations, including those related to packaging materials. Failing to comply with these regulations can result in costly recalls, fines, and reputational damage.

Ensuring Product Safety and Efficacy MCA helps manufacturers identify potential hazards associated with packaging materials, such as contamination, degradation, or migration of substances that may compromise product performance or patient safety.

Reducing Risk and Liability By verifying the composition of packaging materials, manufacturers can minimize their liability in case of adverse events or product failures.

Improving Supply Chain Management MCA enables manufacturers to make informed decisions about supplier selection, material sourcing, and inventory management.

Key Benefits of Material Composition Analysis for Medical Device Packaging Materials

Here are some key benefits of using MCA for medical device packaging materials

Enhanced Product Quality By identifying potential issues with packaging materials, manufacturers can improve product quality, reduce defects, and enhance overall performance.

Increased Efficiency Streamlined material sourcing, supplier management, and inventory control processes enable businesses to operate more efficiently and cost-effectively.

Improved Brand Reputation Demonstrating a commitment to regulatory compliance, product safety, and quality can help manufacturers build trust with customers, investors, and stakeholders.

QA Frequently Asked Questions about Material Composition Analysis for Medical Device Packaging Materials

Here are some frequently asked questions about MCA

What types of packaging materials require Material Composition Analysis?

All medical device packaging materials, including films, foams, tapes, labels, and inserts, may be subject to MCA.

How does Eurolabs laboratory service support my business needs?

Our expert team provides comprehensive analysis, accurate reporting, and tailored solutions to help you navigate the complex regulatory environment.

What are the common elements detected in Material Composition Analysis for medical device packaging materials?

Heavy metals (e.g., lead, cadmium), plastics (e.g., PVC, PET), adhesives, and other additives may be detected in MCA tests.

How do I ensure compliance with regulatory requirements through Material Composition Analysis?

By verifying the composition of packaging materials, you can demonstrate compliance with regulations, reduce risk, and improve product quality.

Conclusion

Material Composition Analysis for medical device packaging materials is a critical laboratory service that enables manufacturers to verify the safety and efficacy of their products. At Eurolab, we understand the importance of MCA in todays highly regulated industry and offer a comprehensive solution to support your business needs. By leveraging our expert team, cutting-edge technology, and tailored services, you can ensure compliance with regulatory requirements, reduce risk, and improve product quality.

Contact us today to learn more about how Eurolabs Material Composition Analysis can help your business thrive in the competitive medical device market.