Finite element analysis (FEA) in stress testing

Unlocking the Power of Finite Element Analysis (FEA) in Stress Testing Enhancing Product Reliability and Efficiency

In todays fast-paced business environment, companies are constantly striving to improve product performance, reduce costs, and increase efficiency. One critical aspect of achieving these goals is ensuring that products can withstand various types of stress and loads without compromising their structural integrity or functionality. This is where Finite Element Analysis (FEA) in stress testing comes into play a powerful laboratory service provided by Eurolab that enables businesses to simulate real-world conditions, identify potential vulnerabilities, and optimize product design.

What is Finite Element Analysis (FEA)?

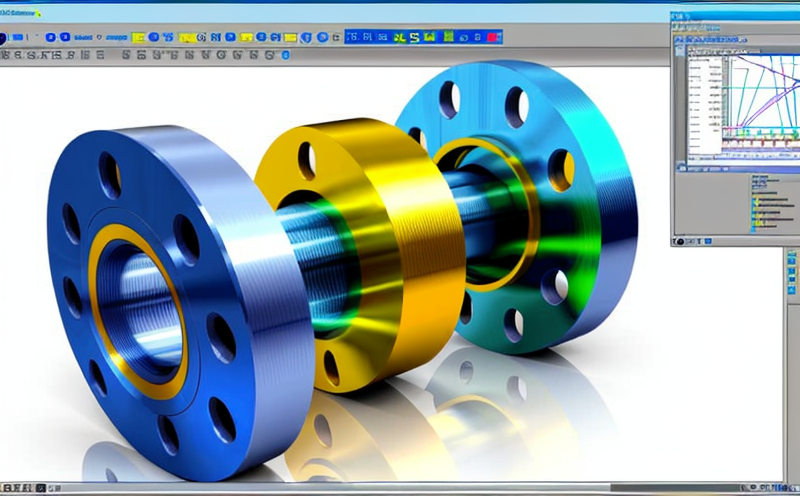

Finite Element Analysis (FEA) is a computational method used to model complex physical systems, such as structures, materials, and mechanisms. It involves dividing the system into small, manageable elements, called finite elements, which are analyzed independently to predict their behavior under various loads and conditions. This approach allows engineers to simulate real-world scenarios, reducing the need for physical prototypes and minimizing the risk of product failure.

Why is Finite Element Analysis (FEA) in stress testing essential?

The increasing complexity of modern products has made it more challenging than ever to ensure their reliability and performance. Traditional testing methods often rely on physical prototypes, which can be time-consuming, expensive, and sometimes inaccurate. FEA in stress testing offers a game-changing solution by providing a virtual laboratory environment where engineers can simulate various loads, temperatures, and environmental conditions.

With FEA in stress testing, businesses can

Reduce the risk of product failure By identifying potential weaknesses and vulnerabilities early on, companies can avoid costly recalls, damage to reputation, and loss of customer trust.

Increase design efficiency FEA enables engineers to optimize product design, reducing material usage, weight, and complexity while improving overall performance.

Shorten development timelines Virtual testing eliminates the need for physical prototypes, accelerating the development process and getting products to market faster.

Minimize costs By identifying potential issues before production, companies can avoid costly rework, revisions, or even complete redesigns.

Advantages of using Finite Element Analysis (FEA) in stress testing

Eurolabs FEA in stress testing offers numerous benefits that set it apart from traditional testing methods. Some key advantages include

Accurate predictions FEA models can accurately predict product behavior under various loads and conditions, reducing the risk of unexpected failures.

Cost savings By identifying potential issues early on, companies can avoid costly redesigns or rework, saving time and resources.

Increased precision FEA enables engineers to simulate complex scenarios with high accuracy, reducing the need for physical prototypes and minimizing the risk of errors.

Scalability Virtual testing allows companies to analyze large-scale systems and materials with ease, making it an ideal solution for industries such as aerospace, automotive, or construction.

Improved design optimization FEA enables engineers to optimize product design, reducing material usage, weight, and complexity while improving overall performance.

Key benefits of using Eurolabs FEA in stress testing

Some key benefits of choosing Eurolabs FEA in stress testing include

Expertise and experience Our team of certified engineers has extensive experience in FEA modeling and analysis, ensuring accurate results and reliable solutions.

State-of-the-art software We utilize the latest FEA software, such as Abaqus, ANSYS, or NASTRAN, to ensure precise simulations and detailed results.

Scalability and flexibility Our virtual laboratory environment allows us to simulate complex systems, materials, and conditions with ease.

Customized solutions We work closely with clients to develop tailored FEA models that meet their specific needs and requirements.

Timely delivery Our experienced team ensures prompt delivery of high-quality results, allowing companies to make informed decisions quickly.

Frequently Asked Questions (FAQs)

Q What types of products can be analyzed using Finite Element Analysis (FEA)?

A FEA can be applied to a wide range of products and systems, including mechanical components, structures, materials, and mechanisms.

Q How does Eurolabs FEA in stress testing differ from traditional testing methods?

A Our virtual laboratory environment allows for accurate simulations, precise results, and reduced costs compared to physical prototypes or lab testing.

Q What are the benefits of using Finite Element Analysis (FEA) over other simulation tools?

A FEA offers high accuracy, flexibility, and scalability, making it an ideal solution for complex systems and materials analysis.

Q How can I get started with Eurolabs FEA in stress testing service?

A Simply contact our team to discuss your project requirements, and well guide you through the process of developing a customized FEA model.

Conclusion

In todays competitive business landscape, companies need innovative solutions that enhance product performance, reduce costs, and increase efficiency. Finite Element Analysis (FEA) in stress testing provided by Eurolab is an essential tool for businesses seeking to simulate real-world conditions, identify potential vulnerabilities, and optimize product design. By leveraging the power of FEA, companies can unlock new levels of innovation, competitiveness, and growth.

Contact us today to learn more about how Eurolabs FEA in stress testing can help your business thrive!