Impact of stress analysis on machine design

Unlock the Secrets to Machine Design with Stress Analysis Why Eurolabs Expert Service is a Game-Changer for Businesses

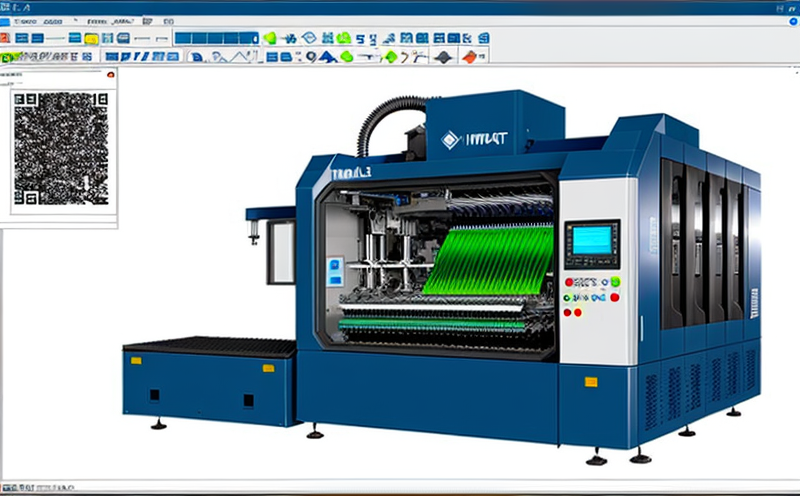

In todays fast-paced industrial landscape, designing machines that are efficient, reliable, and safe is a top priority for businesses across various sectors. However, creating such machines requires more than just expertise in mechanical engineering; it demands a deep understanding of the intricate forces at play within the machine itself. This is where stress analysis comes into the picture an essential tool that helps designers predict and mitigate potential weaknesses in their creations.

Stress analysis, also known as finite element analysis (FEA), is a laboratory service provided by Eurolab that utilizes advanced computational methods to simulate the behavior of materials under various types of loading. By analyzing the stresses that machines are subjected to during operation, manufacturers can identify areas of potential failure and make data-driven decisions to optimize their designs.

In this article, we will delve into the impact of stress analysis on machine design and explore why Eurolabs expert service is a must-have for businesses seeking to revolutionize their product development process.

The Importance of Stress Analysis in Machine Design

Machines are complex systems that involve numerous components working together in harmony. However, this complexity can lead to unexpected failures if not properly managed. A single point of failure can have catastrophic consequences, resulting in costly downtime, damaged equipment, and even loss of life.

Stress analysis helps designers anticipate and mitigate these risks by

Predicting material fatigue and potential failure points

Optimizing component design for improved performance and efficiency

Reducing the risk of mechanical failures and associated costs

Enhancing overall machine reliability and lifespan

Advantages of Using Stress Analysis in Machine Design

Eurolabs stress analysis service offers a wide range of benefits that can transform your business. Here are just a few key advantages

Improved Product Reliability By identifying potential weaknesses before manufacturing, you can design machines with enhanced reliability, reducing the likelihood of costly repairs and downtime.

Enhanced Efficiency Stress analysis enables designers to optimize machine performance by minimizing energy consumption, improving speed, and maximizing productivity.

Reduced Material Waste By simulating various loading scenarios, manufacturers can reduce material waste by selecting the most suitable materials for each component.

Increased Design Confidence With stress analysis results in hand, you can have complete confidence in your designs, ensuring that your machines meet or exceed industry standards.

Key Benefits of Eurolabs Stress Analysis Service

At Eurolab, we understand the complexities of machine design and offer a comprehensive range of stress analysis services tailored to your specific needs. Here are just some of the key benefits you can expect

Accurate Predictive Modeling Our expert engineers utilize advanced computational methods to simulate real-world loading conditions, ensuring that our predictions are as accurate as possible.

Customized Solutions We work closely with clients to understand their unique requirements and develop bespoke stress analysis solutions that meet their specific needs.

Timely Results With a focus on efficiency and speed, we deliver results quickly, allowing you to incorporate them into your design process without delay.

How Stress Analysis Works

The process of conducting a stress analysis involves several key steps

Data Collection Our team gathers data about the machines design, including component specifications, material properties, and operating conditions.

Model Development We create a 3D model of the machine using specialized software, taking into account all relevant factors such as load distribution, boundary conditions, and material behavior.

Simulation Advanced computational methods are applied to simulate various loading scenarios, including static loads, dynamic forces, and thermal effects.

Results Analysis Our experts analyze the simulation results to identify areas of high stress concentration, fatigue, or potential failure points.

Common Applications of Stress Analysis in Machine Design

Stress analysis is a versatile tool with applications across various industries, including

Aerospace Engineering Predicting material performance under extreme conditions, such as temperature fluctuations and vibrations.

Automotive Industry Optimizing engine components for improved efficiency and reliability.

Oil and Gas Sector Analyzing equipment for high-pressure systems to prevent catastrophic failures.

QA Section

Still have questions about the impact of stress analysis on machine design? Here are some frequently asked questions and answers

Q What is the difference between stress analysis and finite element analysis (FEA)?

A Stress analysis encompasses a broader range of methods, including FEA. While FEA is a specific computational technique used to simulate material behavior under various loads, stress analysis involves other tools and methodologies as well.

Q Can I conduct stress analysis in-house or should I outsource it?

A Both options have their merits. Conducting stress analysis in-house can be time-consuming and requires significant expertise. Outsourcing to a specialized laboratory like Eurolab ensures accurate results while minimizing the risk of human error.

Q How long does a typical stress analysis project take?

A Project duration varies depending on complexity, data availability, and computational requirements. However, our team at Eurolab strives to deliver results within 2-4 weeks, allowing you to incorporate them into your design process quickly.

Conclusion

In todays fast-paced industrial landscape, businesses cannot afford to compromise on machine reliability, efficiency, or safety. By harnessing the power of stress analysis, manufacturers can unlock the secrets to designing machines that meet or exceed industry standards. At Eurolab, our expert team is dedicated to providing high-quality stress analysis services tailored to your specific needs.

Whether youre looking to improve product reliability, enhance efficiency, or reduce material waste, we invite you to experience the transformative impact of stress analysis for yourself. Contact us today to discuss how our laboratory service can revolutionize your machine design process and take your business to new heights!