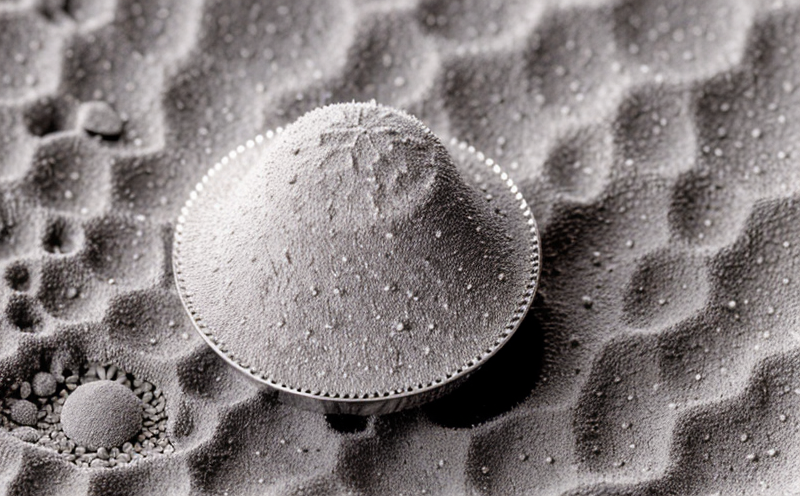

Grain size measurement using electron microscopy (SEM)

Unlocking the Secrets of Grain Size Measurement Revolutionizing Your Industry with Eurolabs Advanced Electron Microscopy (SEM) Services

In todays fast-paced business landscape, precision and accuracy are crucial for driving innovation, improving efficiency, and making informed decisions. One critical aspect that often gets overlooked is material characterization, particularly grain size measurement. This essential parameter plays a vital role in determining the properties and performance of materials used across various industries, from aerospace to healthcare.

Grain size measurement using electron microscopy (SEM) is a highly specialized laboratory service that allows businesses to accurately determine the size and distribution of grains within their materials. By leveraging Eurolabs cutting-edge technology and expertise, you can unlock valuable insights into your materials structure, enabling informed decision-making and driving business success.

The Importance of Grain Size Measurement

Grain size measurement is a critical aspect of understanding the microstructure of materials. Grains are the building blocks of polycrystalline materials, and their size and distribution significantly influence the materials mechanical, thermal, and electrical properties. Accurate grain size measurement is essential for

Predicting material behavior By knowing the grain size, you can predict how your material will behave under various conditions, such as temperature, stress, or strain.

Improving material performance Understanding the grain size distribution enables you to optimize the materials composition and processing conditions to achieve desired properties.

Enhancing product reliability Accurate grain size measurement reduces the risk of defects and failures, ensuring that your products meet the required standards.

The Benefits of Grain Size Measurement using Electron Microscopy (SEM)

Eurolabs advanced SEM services offer numerous advantages over traditional methods

High precision and accuracy SEM provides ultra-high-resolution images, allowing for precise grain size measurement with a margin of error as low as 1-

Fast turnaround times Our state-of-the-art equipment enables rapid sample analysis, ensuring you receive results quickly to inform your decision-making process.

Non-destructive testing SEM is a non-invasive technique that preserves the integrity of your samples, making it ideal for research and development, quality control, and failure analysis.

Comprehensive data analysis Our team provides detailed reports, including grain size distribution plots, histograms, and statistical analysis to help you interpret the results.

Scalability Eurolabs SEM services cater to a wide range of sample sizes, from nanoscale materials to macroscopic components.

Key Benefits for Businesses

Eurolabs grain size measurement using electron microscopy (SEM) service offers numerous benefits for businesses

Improved product quality Accurate grain size measurement ensures that your products meet the required standards, reducing defects and failures.

Enhanced competitiveness By leveraging Eurolabs expertise and technology, you can gain a competitive edge in the market by offering high-quality products with improved performance.

Cost savings Avoiding costly rework or material waste due to inaccurate measurements translates into significant cost savings for your business.

QA Frequently Asked Questions about Grain Size Measurement using Electron Microscopy (SEM)

What is electron microscopy (SEM)?

Electron microscopy (SEM) is a laboratory technique that uses a focused beam of electrons to produce high-resolution images of materials at the nanoscale.

How does SEM measure grain size?

Eurolabs advanced SEM equipment allows for precise measurement of grain sizes by analyzing the distribution and arrangement of grains within the material.

What types of samples can be analyzed using SEM?

Our SEM services cater to a wide range of materials, including metals, ceramics, polymers, and composites.

Can I get my sample analyzed quickly?

Yes, our state-of-the-art equipment enables rapid sample analysis, ensuring you receive results promptly to inform your decision-making process.

Will my sample be damaged during the measurement process?

No, SEM is a non-destructive testing technique that preserves the integrity of your samples.

How do I prepare my sample for analysis?

Eurolabs experienced team will guide you through the preparation process to ensure your sample is properly prepared for analysis.

Conclusion

Grain size measurement using electron microscopy (SEM) is a critical aspect of material characterization that offers numerous benefits for businesses across various industries. By leveraging Eurolabs advanced technology and expertise, you can unlock valuable insights into your materials structure, driving informed decision-making and business success.

Dont compromise on precision and accuracy choose Eurolab for your grain size measurement needs. Contact us today to learn more about our laboratory services and how we can help you achieve your goals.