Grain structure analysis in weld zones

Unlocking the Secrets of Weld Quality Grain Structure Analysis in Weld Zones by Eurolab

As industries continue to push the boundaries of innovation and efficiency, the importance of ensuring weld quality cannot be overstated. A single faulty weld can compromise an entire structure, putting peoples lives at risk and resulting in significant financial losses. In this era of precision engineering, businesses need a reliable partner to provide them with the insights they need to optimize their welding processes.

Grain structure analysis in weld zones is one such service that has revolutionized the way industries approach weld quality control. At Eurolab, our team of experts utilizes cutting-edge technology and techniques to analyze the grain structure within weld zones, providing businesses with a comprehensive understanding of their materials behavior under various conditions.

What is Grain Structure Analysis in Weld Zones?

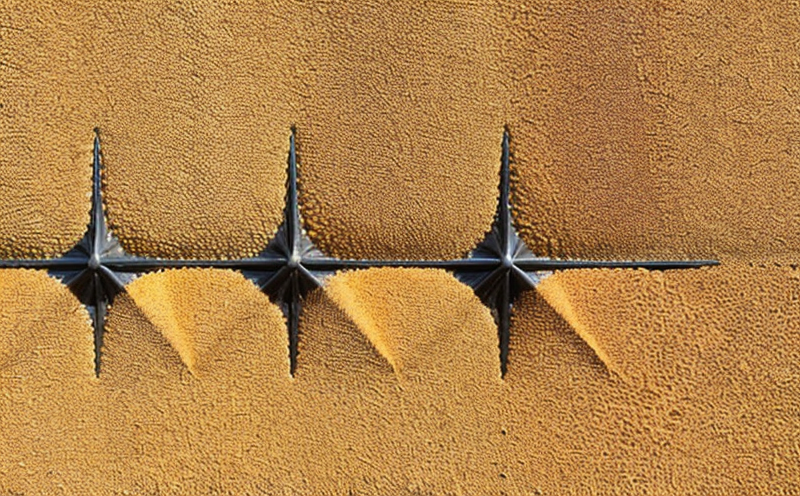

Grain structure analysis in weld zones refers to the examination of the crystallographic structure of metals within the weld region. This process involves using specialized equipment to visualize and measure the grain size, shape, and orientation within the weld. By analyzing the grain structure, businesses can gain a deeper understanding of their materials properties, such as its strength, ductility, and resistance to corrosion.

Grain structure analysis in weld zones is particularly important for industries that rely heavily on welding processes, including

Aerospace

Automotive

Oil and Gas

Energy

Construction

The Advantages of Grain Structure Analysis in Weld Zones

At Eurolab, we understand the significance of grain structure analysis in weld zones. Here are some key benefits our service provides

Improved Weld Quality By identifying potential defects and anomalies within the weld zone, businesses can take corrective action to ensure that their products meet the highest standards of quality.

Enhanced Material Properties Understanding the grain structure within the weld region allows for the optimization of material properties, leading to improved performance under various conditions.

Increased Efficiency With accurate information on material behavior, businesses can streamline their production processes, reducing downtime and costs associated with rework or repair.

Compliance and Certification Grain structure analysis in weld zones is a critical aspect of meeting industry-specific regulations and standards. Our service ensures that your products meet the required specifications for certification.

Some key benefits of our grain structure analysis in weld zones include

Benefits of Using Eurolabs Services

Quick Turnaround Times Our state-of-the-art equipment and expert technicians enable us to deliver results quickly, minimizing downtime and getting you back on track.

Expert Analysis Our team of experienced analysts provides thorough and accurate interpretations of the data, ensuring that our clients have a comprehensive understanding of their materials behavior.

Cost-Effective Solution By identifying potential issues early on, businesses can avoid costly rework or repair, making our service an attractive option for those looking to optimize their bottom line.

How Does Grain Structure Analysis in Weld Zones Work?

Our grain structure analysis in weld zones involves the following steps

Sample Preparation We carefully select and prepare a representative sample from the weld zone.

Microscopy Our advanced microscopy equipment, such as scanning electron microscopes (SEM), is used to visualize the grain structure within the weld region.

Image Analysis Using specialized software, our analysts measure and analyze the grain size, shape, and orientation within the weld zone.

Reporting and Interpretation A comprehensive report detailing the findings is provided, along with expert interpretation of the data.

Frequently Asked Questions

At Eurolab, we understand that our clients may have questions about our services. Here are some answers to frequently asked questions

Q What types of materials can be analyzed using grain structure analysis in weld zones?

A Our service is applicable to a wide range of metallic materials, including steels, aluminum alloys, titanium alloys, and more.

Q How long does the analysis process take?

A The turnaround time for our services varies depending on the complexity of the project. However, we typically deliver results within 24-48 hours.

Q Can I request a specific method or technique for my analysis?

A Yes, please contact us to discuss your requirements and preferences. Our team will work with you to determine the most suitable approach for your project.

Conclusion

Grain structure analysis in weld zones is an indispensable tool for businesses looking to optimize their welding processes and ensure product quality. At Eurolab, our state-of-the-art facilities and expert technicians provide a comprehensive solution for industries that rely on welding. By partnering with us, you can unlock the secrets of your materials behavior and take advantage of improved efficiency, reduced costs, and enhanced compliance.

Contact us today to learn more about how our grain structure analysis in weld zones service can benefit your business.