The Crucial Role of Hardness Measurement in Ensuring Material Quality A Game-Changer for Businesses

In todays fast-paced and competitive business landscape, manufacturers and industries rely heavily on precise material testing to guarantee the quality and performance of their products. Among various laboratory services, Hardness Measurement stands out as a vital tool that helps businesses ensure the reliability and durability of their materials. At Eurolab, we offer expert Hardness Measurement services that enable companies to make informed decisions, optimize production processes, and stay ahead in the market.

What is Hardness Measurement?

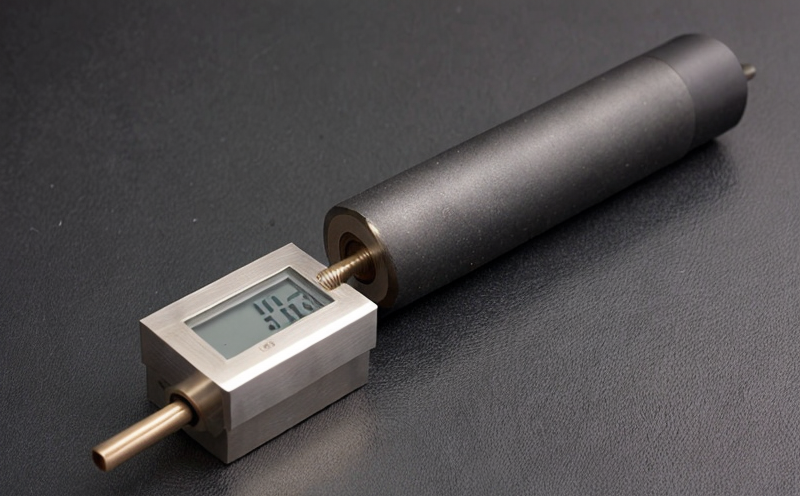

Hardness Measurement is a non-destructive laboratory test that evaluates the resistance of a material to deformation or penetration. It measures the hardness of materials on a standardized scale, providing valuable insights into their mechanical properties. This test is essential for industries such as aerospace, automotive, construction, and more, where materials durability and performance directly impact product safety, efficiency, and lifespan.

Why is Hardness Measurement Essential for Businesses?

In todays competitive market, businesses need to ensure that their products meet the highest quality standards. Hardness Measurement plays a critical role in achieving this goal by

Ensuring Material Reliability By accurately measuring material hardness, companies can guarantee the reliability and performance of their products, reducing the risk of failures and recalls.

Optimizing Production Processes With precise hardness data, manufacturers can fine-tune production processes to minimize waste, reduce costs, and improve product consistency.

Enhancing Product Safety Hardness Measurement helps industries ensure compliance with regulatory requirements, protecting consumers from potentially hazardous products.

Improving Material Selection Accurate hardness measurements enable companies to select the most suitable materials for their applications, reducing the risk of material failure and associated costs.

Reducing Costs By identifying potential material weaknesses early on, businesses can avoid costly rework, repair, or replacement of defective products.

The Benefits of Hardness Measurement at Eurolab

Our expert team at Eurolab offers comprehensive Hardness Measurement services that go beyond mere testing. Our benefits include

Accurate and Reliable Results We use state-of-the-art equipment and follow strict quality control procedures to ensure accurate and reliable hardness measurements.

Comprehensive Reporting Our detailed reports provide clear, easy-to-understand results, enabling you to make informed decisions about material selection and production processes.

Expert Consultation Our experienced technicians are available to answer your questions, provide guidance on test interpretation, and help optimize your testing protocols.

Flexible Scheduling We offer flexible scheduling options to accommodate your busy schedule, ensuring minimal downtime and disruption to your operations.

ISO/IEC 17025 Accreditation Our laboratory is fully accredited by a recognized accrediting body, guaranteeing the highest standards of quality and integrity.

Frequently Asked Questions (FAQs)

Q What types of materials can be tested for hardness?

A We test a wide range of materials, including metals, plastics, ceramics, and composites.

Q How do you determine which hardness testing method to use?

A Our experienced technicians select the most suitable testing method based on the materials properties, size, and shape.

Q Can I get my samples tested immediately?

A Yes, we offer fast turnaround times for most tests. Please contact us for specific information.

Q What if my sample fails a hardness test?

A If your sample does not meet required standards, our team will work with you to determine the best course of action and provide recommendations for material selection or modification.

Q Do you offer any special testing services or customized testing protocols?

A Yes, we can develop customized testing protocols tailored to your specific needs and requirements.

Conclusion

Hardness Measurement is a critical component of any quality control program. By partnering with Eurolab, businesses can ensure the reliability and performance of their products, optimize production processes, and stay ahead in the market. Our expert team provides accurate, reliable results, comprehensive reporting, and flexible scheduling options to meet your specific needs.

Dont compromise on material quality trust Eurolab for all your Hardness Measurement requirements. Contact us today to learn more about our services and how we can help you achieve your business goals.