Indentation shape validation

The Importance of Indentation Shape Validation Ensuring Quality and Consistency in Your Products

In todays fast-paced business world, ensuring the quality and consistency of your products is crucial for maintaining a competitive edge. One often-overlooked aspect of product validation is indentation shape validation. This laboratory service, provided by Eurolab, plays a vital role in verifying the integrity and accuracy of various materials, including plastics, metals, and composites.

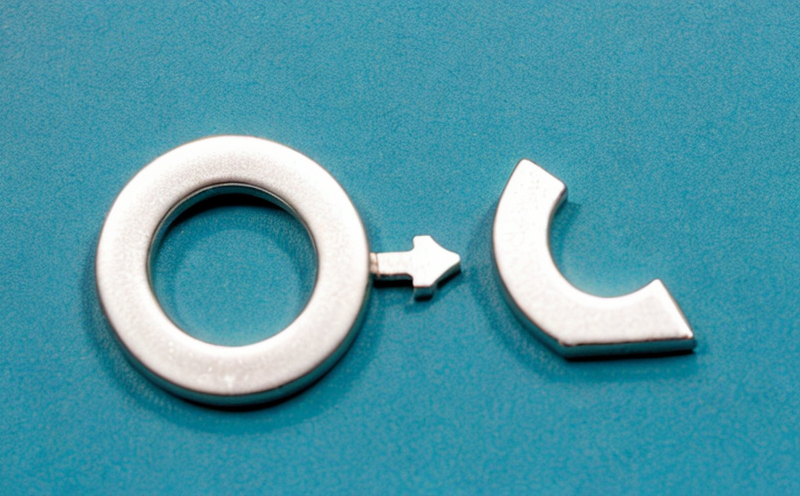

What is Indentation Shape Validation?

Indentation shape validation involves testing the shape and deformation characteristics of indented surfaces using specialized equipment and techniques. This process helps to evaluate the mechanical properties of materials under specific conditions, providing valuable insights into their behavior under stress, strain, and other environmental factors.

In simple terms, indentation shape validation ensures that your products meet the required standards and specifications for shape retention, dimensional stability, and surface finish. By validating the indentation shapes of your products, you can

Improve quality control Identify defects or inconsistencies in the production process, enabling you to implement corrective actions.

Enhance product performance Validate the mechanical properties of materials, ensuring that they meet the required specifications for withstanding various loads and stresses.

Reduce costs Minimize waste and rework by identifying potential issues early on, reducing the need for costly revisions or replacements.

Advantages of Indentation Shape Validation

The benefits of indentation shape validation extend far beyond mere quality control. By incorporating this service into your production process, you can

Key Benefits

Improved accuracy Ensure that your products meet precise specifications and tolerances, reducing the risk of defects and rework.

Enhanced material properties Validate the mechanical properties of materials, enabling you to optimize their performance and durability.

Increased efficiency Streamline production processes by identifying potential issues early on, reducing waste and minimizing costs.

Better customer satisfaction Deliver high-quality products that meet or exceed customer expectations, fostering loyalty and trust.

QA Section

Weve compiled a comprehensive QA section to address any questions you may have about indentation shape validation

What types of materials can be tested using indentation shape validation?

Indentation shape validation can be applied to various materials, including plastics, metals, composites, ceramics, and more. Our team at Eurolab will work with you to determine the best testing methods for your specific needs.

How does indentation shape validation differ from other laboratory services?

Indentation shape validation is a unique service that focuses specifically on evaluating the shape and deformation characteristics of indented surfaces. While other laboratory services may test material properties, indentation shape validation provides a more nuanced understanding of material behavior under specific conditions.

Can indentation shape validation help me identify potential issues in my production process?

Absolutely! Indentation shape validation can help you identify defects or inconsistencies in your production process, enabling you to implement corrective actions and improve overall quality control.

How long does the indentation shape validation process typically take?

The duration of the indentation shape validation process varies depending on the scope of testing required. Our team at Eurolab will work with you to develop a customized testing plan that meets your needs and ensures timely results.

Conclusion

Indentation shape validation is an essential laboratory service that helps businesses ensure quality and consistency in their products. By incorporating this service into your production process, you can improve accuracy, enhance material properties, increase efficiency, and better satisfy customer expectations. Contact Eurolab today to learn more about our indentation shape validation services and take the first step towards delivering high-quality products that meet or exceed industry standards.