Leakage Current Testing in HVAC System Components

The Critical Importance of Leakage Current Testing in HVAC System Components Protecting Your Business from Electrical Hazards

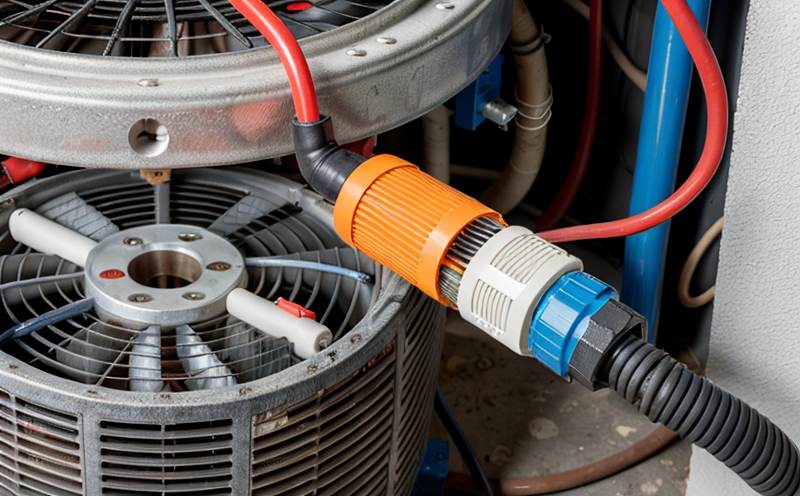

As a business owner, youre likely aware of the importance of regular maintenance and testing to ensure the optimal performance and safety of your heating, ventilation, and air conditioning (HVAC) system. However, theres one critical aspect that often gets overlooked leakage current testing in HVAC system components. This laboratory service is essential for preventing electrical hazards, reducing downtime, and saving you money in the long run.

At Eurolab, we specialize in providing comprehensive laboratory services, including Leakage Current Testing in HVAC System Components. Our expert technicians utilize state-of-the-art equipment to detect even the smallest amounts of electrical leakage, ensuring your business remains safe and compliant with industry regulations.

What is Leakage Current Testing in HVAC System Components?

Leakage current testing involves measuring the flow of electric current from a circuit or component to ground or another exposed metal part. In HVAC systems, this can occur through various means, including worn-out insulation, damaged wiring, or malfunctioning components. When electrical leakage occurs, it can cause a range of issues, from minor shocks and sparks to catastrophic equipment failure and even fires.

Regular Leakage Current Testing in HVAC System Components helps identify potential hazards before they become major problems. By detecting and addressing electrical leaks promptly, you can

Prevent equipment damage and reduce downtime

Minimize energy consumption and lower costs

Ensure employee safety and compliance with industry regulations

Extend the lifespan of your HVAC system components

The Advantages of Using Leakage Current Testing in HVAC System Components

Our expert technicians at Eurolab have identified several key benefits to incorporating Leakage Current Testing in HVAC System Components into your regular maintenance routine. Here are just a few

Prevents Equipment Damage and Downtime Electrical leaks can cause damage to sensitive equipment, leading to costly repairs or even replacement. Regular testing helps identify potential hazards before they become major problems.

Saves Energy and Reduces Costs By detecting electrical leaks, you can prevent unnecessary energy consumption and reduce your utility bills.

Ensures Employee Safety and Compliance Electrical shocks and sparks can be hazardous for employees working with HVAC systems. Our tests help ensure that your workplace remains safe and compliant with industry regulations.

Extends Component Lifespan Regular testing helps identify potential issues before they cause damage to components, extending their lifespan and reducing the need for premature replacements.

Enhances System Performance By detecting and addressing electrical leaks, you can optimize system performance, improving airflow, temperature control, and overall efficiency.

Reduces Liability and Insurance Costs A safe and compliant workplace reduces your liability and insurance costs, providing peace of mind for business owners.

How Does Leakage Current Testing Work?

Our expert technicians at Eurolab employ specialized equipment to detect even the smallest amounts of electrical leakage. The testing process typically involves

Preparation Our technicians inspect the HVAC system components and ensure they are in a safe condition for testing.

Measurement We use specialized meters or sensors to measure the flow of electric current from a circuit or component to ground or another exposed metal part.

Analysis We analyze the data collected during testing, identifying potential electrical leaks and determining their severity.

QA Section

Weve compiled a comprehensive QA section to address common questions about Leakage Current Testing in HVAC System Components

Q1 Why is regular leakage current testing necessary?

A1 Regular leakage current testing helps identify potential hazards before they become major problems, preventing equipment damage, energy waste, and employee injuries.

Q2 What happens if I ignore electrical leaks?

A2 Ignoring electrical leaks can lead to catastrophic equipment failure, fires, and even fatalities. Regular testing is essential for ensuring a safe and compliant workplace.

Q3 How often should I schedule leakage current testing?

A3 The frequency of testing depends on various factors, including the age and condition of your HVAC system components. Our technicians can recommend a customized testing schedule tailored to your specific needs.

Q4 Can I perform leakage current testing in-house?

A4 While its technically possible to perform in-house tests, our expert technicians at Eurolab utilize specialized equipment and follow industry-recognized protocols to ensure accurate and reliable results.

Conclusion

In conclusion, Leakage Current Testing in HVAC System Components is an essential laboratory service for businesses looking to protect their employees, assets, and reputation. By incorporating regular testing into your maintenance routine, you can prevent electrical hazards, reduce downtime, and save money in the long run.

At Eurolab, were committed to providing exceptional laboratory services, including Leakage Current Testing in HVAC System Components. Our expert technicians will work closely with you to develop a customized testing schedule tailored to your specific needs.

Dont wait until its too late contact us today to schedule your next leakage current test and ensure your business remains safe, compliant, and profitable.

---

About Eurolab

At Eurolab, were dedicated to providing cutting-edge laboratory services for businesses of all sizes. Our team of expert technicians employs state-of-the-art equipment and industry-recognized protocols to deliver accurate and reliable results. Trust us with your laboratory needs contact us today to learn more about our comprehensive range of services.