Testing Electrical Components for Overheating in HVAC Systems

Testing Electrical Components for Overheating in HVAC Systems A Crucial Service for Businesses

In todays fast-paced business environment, ensuring the reliability and efficiency of critical systems is paramount to maintaining productivity and profitability. One such system that requires regular maintenance is the heating, ventilation, and air conditioning (HVAC) system. These complex systems are prone to overheating, which can lead to equipment failure, costly repairs, and even downtime. At Eurolab, we understand the importance of testing electrical components for overheating in HVAC systems, and our laboratory service is designed to help businesses like yours identify potential issues before they become major problems.

What is Testing Electrical Components for Overheating in HVAC Systems?

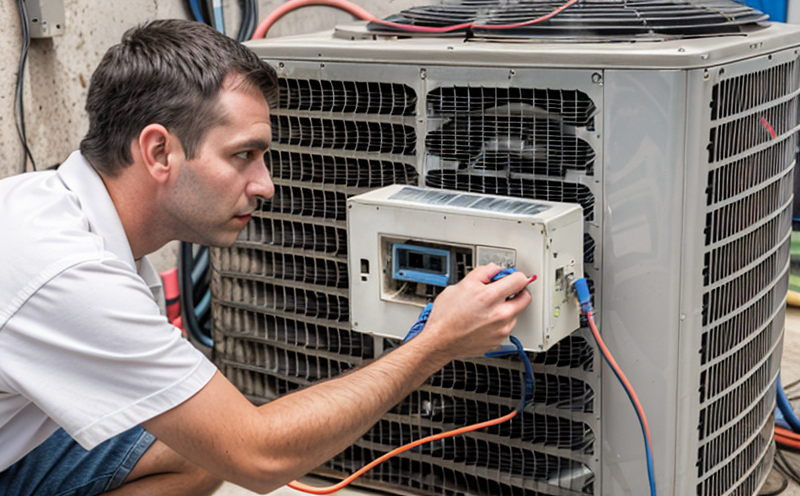

Testing electrical components for overheating in HVAC systems involves a thorough examination of the systems electrical components to detect any signs of excessive heat generation. This includes analyzing temperature readings, voltage and current fluctuations, and other performance metrics to determine if any component is operating outside its safe temperature range. Our expert technicians use advanced equipment and techniques to pinpoint potential hotspots within the system, enabling businesses to take corrective action before a catastrophic failure occurs.

Why is Testing Electrical Components for Overheating in HVAC Systems Essential?

In todays energy-conscious world, maintaining efficient HVAC systems is crucial for reducing operating costs and minimizing environmental impact. Here are some compelling reasons why testing electrical components for overheating in HVAC systems should be an integral part of your maintenance routine

Prevents Equipment Failure Regular testing helps identify potential hotspots within the system, allowing you to replace or repair faulty components before they cause equipment failure.

Reduces Downtime By identifying and addressing overheating issues promptly, you can minimize downtime and ensure continuous operation of critical systems.

Saves Energy Costs Efficient HVAC systems consume less energy, resulting in significant cost savings over time.

Extends Equipment Lifespan Regular maintenance helps extend the lifespan of your equipment, reducing replacement costs and minimizing waste.

Enhances Indoor Air Quality Properly functioning HVAC systems help maintain indoor air quality, promoting a healthy working environment for employees.

Meets Regulatory Requirements Regular testing helps ensure compliance with industry regulations and standards, reducing the risk of fines and penalties.

Key Benefits of Using Eurolabs Testing Electrical Components for Overheating in HVAC Systems Service

Our laboratory service offers numerous benefits to businesses seeking to maintain efficient and reliable HVAC systems. Here are some key advantages

Comprehensive Analysis Our expert technicians conduct a thorough analysis of the system, identifying potential hotspots and performance issues.

Advanced Equipment We utilize state-of-the-art equipment to measure temperature readings, voltage, and current fluctuations with precision.

Timely Reporting Our team provides timely reporting and recommendations for corrective action, enabling businesses to address issues promptly.

Cost-Effective Solutions We offer cost-effective solutions for component replacement or repair, minimizing downtime and energy costs.

Compliance Assistance Our experts help ensure compliance with industry regulations and standards.

QA Frequently Asked Questions

At Eurolab, we understand that you may have questions about our Testing Electrical Components for Overheating in HVAC Systems service. Here are some frequently asked questions

Q How often should I test my HVAC system?

A Regular testing is recommended every 6-12 months, depending on usage and system type.

Q What types of equipment can be tested?

A Our laboratory service covers a wide range of electrical components, including motors, transformers, circuit breakers, and more.

Q Can you provide repair or replacement services for faulty components?

A Yes, our team offers cost-effective solutions for component replacement or repair.

Q How long does the testing process typically take?

A The duration of the test depends on system complexity and type. Our expert technicians will work with you to schedule a convenient time.

Q Are your services compliant with industry regulations?

A Yes, our laboratory service is designed to meet or exceed industry standards and regulations.

Conclusion

At Eurolab, we understand that testing electrical components for overheating in HVAC systems is a critical aspect of maintaining efficient and reliable systems. Our comprehensive laboratory service is designed to help businesses like yours identify potential issues before they become major problems. By choosing our expert team, you can rest assured that your system will receive the attention it deserves, ensuring continuous operation and minimizing downtime. Contact us today to schedule a testing service and discover how Eurolab can help you save energy costs, extend equipment lifespan, and enhance indoor air quality.