Load-bearing analysis for aerospace fasteners and joints to ensure reliability

The Ultimate Key to Ensuring Reliability in Aerospace Fasteners and Joints Load-bearing Analysis

In the realm of aerospace engineering, reliability is paramount. A single failure can have catastrophic consequences, from costly delays to potential loss of life. To mitigate these risks, manufacturers and engineers rely on rigorous testing and analysis procedures to ensure that their fasteners and joints meet or exceed industry standards.

What is Load-bearing Analysis?

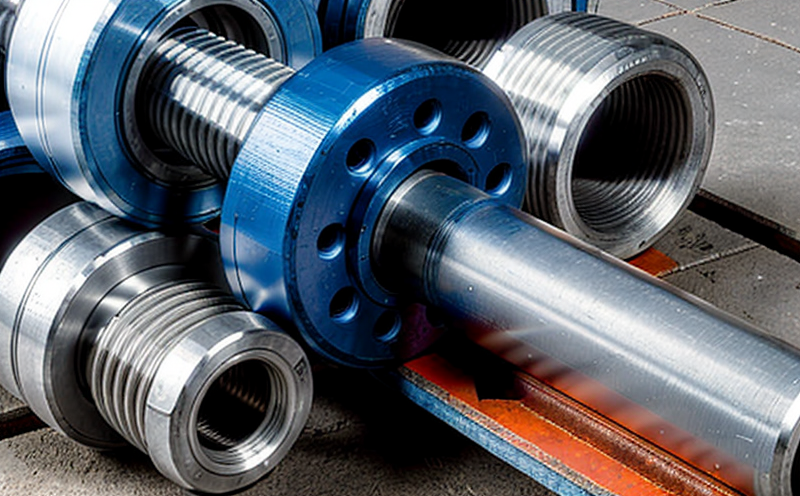

Load-bearing analysis for aerospace fasteners and joints is a laboratory service provided by Eurolab that applies advanced analytical techniques to evaluate the mechanical performance of critical components. This comprehensive evaluation assesses the structural integrity, material properties, and geometric configuration of each component, providing an accurate prediction of its behavior under various loads.

Why is Load-bearing Analysis Essential for Businesses?

The aerospace industry demands perfection. Even minor defects or weaknesses in fasteners and joints can compromise the overall safety and reliability of a system. Load-bearing analysis plays a vital role in identifying and mitigating these risks, ensuring that aerospace components meet the stringent requirements of regulatory bodies and end-users.

Some of the key benefits of using load-bearing analysis for aerospace fasteners and joints to ensure reliability include

Advantages of Load-bearing Analysis

Reduced Risk By evaluating component performance under various loads, manufacturers can identify potential failure points, reducing the risk of catastrophic failures.

Increased Efficiency Load-bearing analysis enables manufacturers to optimize component design, materials, and manufacturing processes, leading to improved efficiency and cost savings.

Improved Safety Rigorous testing and analysis procedures ensure that components meet or exceed industry standards, enhancing overall safety and reliability.

Enhanced Quality Control Eurolabs load-bearing analysis service provides a comprehensive evaluation of component performance, enabling manufacturers to implement effective quality control measures.

Compliance with Industry Standards Load-bearing analysis ensures compliance with regulatory requirements, reducing the risk of costly rework or even facility shutdowns.

Additional Benefits

Design Optimization Load-bearing analysis informs design decisions, allowing engineers to create optimized components that balance performance, weight, and cost.

Material Selection Manufacturers can select materials that meet specific performance requirements, ensuring that components function as intended under various loads.

Manufacturing Process Validation Eurolabs load-bearing analysis service evaluates the effectiveness of manufacturing processes, enabling manufacturers to optimize their workflows and reduce defects.

How Does Load-bearing Analysis Work?

Eurolabs load-bearing analysis service involves a multi-step process

Component Receipt and Inspection Components are received and inspected for any signs of damage or defect.

Material Testing Material properties are evaluated using advanced techniques, such as tensile testing and hardness testing.

Geometric Analysis The geometric configuration of each component is analyzed to ensure compliance with design specifications.

Load-bearing Capacity Evaluation Components are subjected to various loads, including tension, compression, bending, and torsion, to determine their load-bearing capacity.

Data Analysis and Reporting Test data is analyzed and presented in a comprehensive report, detailing component performance and providing recommendations for optimization.

QA Load-bearing Analysis for Aerospace Fasteners and Joints

Q1 What types of components can be evaluated using load-bearing analysis?

A1 Eurolabs load-bearing analysis service evaluates various aerospace fasteners and joints, including bolts, nuts, screws, rivets, and welds.

Q2 How long does a typical load-bearing analysis take?

A2 The duration of a load-bearing analysis varies depending on the complexity of the component and the number of tests required. However, our team at Eurolab strives to complete analyses within 4-6 weeks.

Q3 What types of loads are applied during a load-bearing analysis?

A3 Components are subjected to various loads, including tension, compression, bending, torsion, and cyclic loading.

Q4 Can I obtain certification or compliance with industry standards through Eurolabs load-bearing analysis service?

A4 Yes. Our comprehensive evaluation ensures that components meet or exceed industry standards, enabling manufacturers to obtain the necessary certifications and comply with regulatory requirements.

Conclusion

In conclusion, load-bearing analysis is an essential tool for ensuring reliability in aerospace fasteners and joints. By providing a comprehensive evaluation of component performance, Eurolabs service enables manufacturers to identify potential failure points, optimize design and materials, and enhance quality control measures.

Dont compromise on safety or reliability. Choose Eurolabs load-bearing analysis service to ensure that your aerospace components meet the highest standards of performance and durability.

Get in Touch with Us

At Eurolab, we understand the importance of timely and accurate results. Our experienced team is dedicated to providing exceptional service, ensuring that you receive comprehensive reports and recommendations that inform your manufacturing decisions.

To learn more about our load-bearing analysis service or to discuss how we can help you ensure reliability in your aerospace components, please dont hesitate to contact us.

Together, lets push the boundaries of innovation and safety in the aerospace industry.