Load-bearing analysis for spacecraft materials used under extreme pressures

Unlocking the Secrets of Spacecraft Materials Load-Bearing Analysis for Extreme Pressures

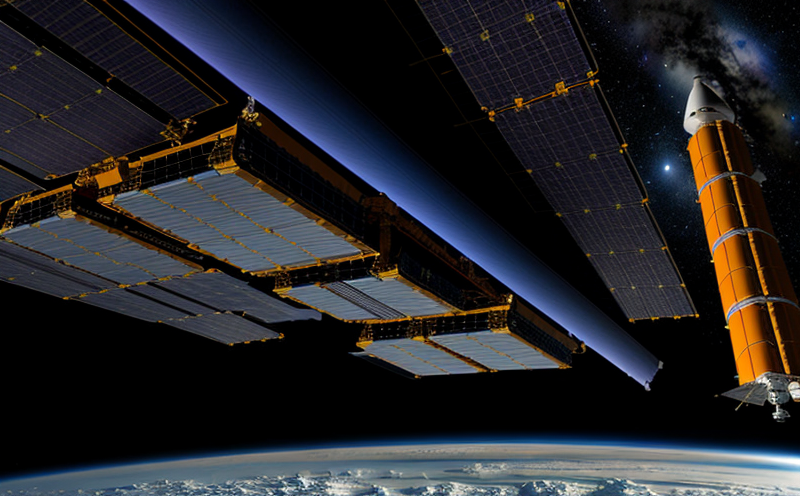

As the space industry continues to push the boundaries of exploration and discovery, the need for advanced materials that can withstand extreme pressures has never been more critical. Spacecraft and their components are subject to immense stressors, including intense heat, radiation, and explosive decompression. To ensure the safety and success of these missions, it is essential to conduct rigorous load-bearing analysis on spacecraft materials used under extreme pressures.

At Eurolab, our team of expert scientists and engineers offers a state-of-the-art laboratory service that provides comprehensive load-bearing analysis for spacecraft materials subjected to extreme pressures. Our cutting-edge facilities and advanced testing equipment enable us to simulate the harshest conditions found in space, providing accurate and reliable results that inform design decisions and ensure mission success.

The Importance of Load-Bearing Analysis

Load-bearing analysis is a critical component of spacecraft material selection and development. By understanding how materials respond to extreme pressures, engineers can optimize their designs to ensure safe and efficient operation. The consequences of failure are dire damaged or failed materials can compromise the entire mission, putting crew members and equipment at risk.

The demand for load-bearing analysis has increased exponentially in recent years, driven by the growing number of commercial space missions and government-funded programs. Companies like SpaceX, Blue Origin, and NASA rely on accurate load-bearing analysis to validate their designs and ensure compliance with regulatory requirements.

Advantages of Load-Bearing Analysis

Our load-bearing analysis services offer numerous benefits for businesses involved in spacecraft development

Improved Material Selection By understanding the mechanical properties of materials under extreme pressures, engineers can select the most suitable materials for each application, reducing the risk of failure and ensuring mission success.

Reduced Design Iterations Accurate load-bearing analysis enables designers to optimize their designs from the outset, minimizing the need for costly redesigns and reducing development time.

Increased Safety By simulating extreme pressure conditions in our laboratory, we can identify potential weaknesses and vulnerabilities, allowing engineers to implement safety measures and mitigate risks.

Compliance with Regulatory Requirements Our load-bearing analysis services ensure compliance with industry standards and regulations, such as NASAs Technical Standard for Materials (NASA-STD-6001).

Cost Savings By identifying material limitations early in the design process, companies can avoid costly rework and redesigns, reducing overall project expenses.

How Load-Bearing Analysis Works

Our load-bearing analysis services involve a range of techniques and methods, including

Material Testing We conduct a series of material tests to determine their mechanical properties under extreme pressures.

Finite Element Modeling (FEM) Our team uses FEM software to simulate the behavior of materials under various loading conditions, allowing us to predict performance and identify potential weaknesses.

Experimental Testing We employ advanced testing equipment to subject materials to extreme pressure conditions, collecting data on their response and behavior.

Key Benefits of Working with Eurolab

At Eurolab, we offer a comprehensive range of services that cater to the unique needs of spacecraft material development. Our team provides

Expertise Our scientists and engineers have extensive experience in load-bearing analysis for spacecraft materials.

State-of-the-Art Facilities We operate advanced laboratory facilities equipped with cutting-edge testing equipment.

Flexibility We offer customized services tailored to meet the specific needs of each project.

QA Load-Bearing Analysis for Spacecraft Materials

Q What types of materials can be analyzed using load-bearing analysis?

A We analyze a wide range of materials, including metals, composites, and ceramics.

Q Can you simulate extreme pressure conditions in your laboratory?

A Yes, our state-of-the-art facilities enable us to subject materials to intense pressure conditions, replicating the stresses found in space environments.

Q What is the typical turnaround time for load-bearing analysis services?

A Our team works efficiently to ensure fast turnaround times, typically delivering results within 6-12 weeks.

Q Do you offer any certifications or compliance testing?

A Yes, we provide certification and compliance testing to meet regulatory requirements, such as NASAs Technical Standard for Materials (NASA-STD-6001).

Conclusion

Load-bearing analysis is a critical component of spacecraft material development, ensuring the safety and success of missions. At Eurolab, our expert team offers comprehensive load-bearing analysis services that cater to the unique needs of businesses involved in spacecraft development. By understanding how materials respond to extreme pressures, engineers can optimize their designs, reduce costs, and ensure compliance with regulatory requirements.

Dont compromise on material performance trust Eurolab for accurate and reliable load-bearing analysis results. Contact us today to learn more about our services and how we can support your next mission.