Methods for coating adhesion testing in defense materials

Methods for Coating Adhesion Testing in Defense Materials Ensuring Durability and Reliability

In the defense industry, materials and coatings play a critical role in ensuring the performance and reliability of military equipment and systems. The adhesion between coatings and substrates is particularly important, as it can directly impact the durability and effectiveness of these materials. Coating adhesion testing is essential to evaluate the bonding strength between coatings and their underlying substrates, which is crucial for maintaining the integrity and functionality of defense materials.

At Eurolab, we offer a comprehensive laboratory service for coating adhesion testing in defense materials, providing critical insights into the performance and reliability of these materials. Our state-of-the-art facilities and expert technicians are dedicated to delivering accurate and reliable results, ensuring that our clients materials meet the highest standards of quality and performance.

Why is Coating Adhesion Testing Essential?

Coating adhesion testing is a critical component of material evaluation in the defense industry. Poor adhesion between coatings and substrates can lead to various problems, including

Reduced durability Coatings with poor adhesion may flake off or detach from the substrate, compromising the overall performance and reliability of the material.

Increased maintenance costs Coating failure due to poor adhesion can result in costly repairs and replacements, which can be particularly problematic for military equipment and systems.

Decreased effectiveness Inadequate coating adhesion can compromise the functionality of defense materials, impacting their ability to perform critical tasks.

Advantages of Methods for Coating Adhesion Testing in Defense Materials

Our laboratory service for coating adhesion testing in defense materials offers numerous benefits, including

Benefits for Manufacturers and Suppliers

Ensure compliance with regulations Our testing services help manufacturers and suppliers meet industry standards and regulatory requirements.

Improve product quality By identifying potential issues related to coating adhesion, we enable our clients to improve the overall performance and reliability of their materials.

Reduce costs Avoiding costly repairs and replacements due to coating failure can save manufacturers and suppliers significant amounts.

Benefits for End-Users

Enhance equipment performance Our testing services help ensure that coatings adhere properly to substrates, improving the functionality and effectiveness of defense equipment and systems.

Increase safety Coating adhesion issues can compromise equipment safety; our testing helps identify potential problems before they become critical concerns.

Optimize maintenance schedules By identifying potential coating adhesion issues, we enable end-users to plan maintenance activities more effectively.

Benefits for Regulatory Bodies

Ensure public safety Our laboratory service supports regulatory bodies in their efforts to ensure the safety and effectiveness of defense materials.

Compliance with standards We help regulatory bodies verify compliance with industry standards and regulations, promoting a safer and more reliable defense sector.

Methods for Coating Adhesion Testing

Eurolab employs a range of methods for coating adhesion testing in defense materials, including

Tape Test (ASTM D3359) This widely used method involves applying tape to the coated surface and measuring the force required to remove it.

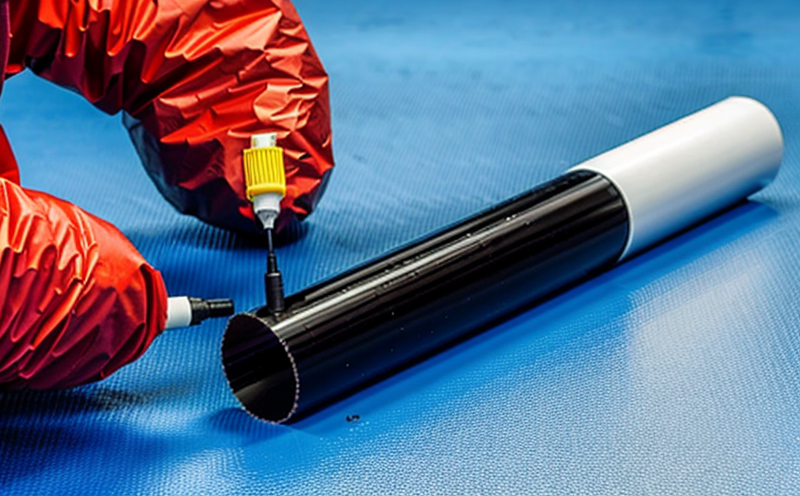

Pull-Off Test (DIN 53164) In this method, a small circular area of the coating is attached to a testing machine, which measures the force required to separate the coating from the substrate.

Scotch Tape Adhesion Test This simple yet effective method involves applying Scotch tape to the coated surface and measuring the amount of adhesive residue left behind.

QA Section

Q What is the purpose of coating adhesion testing in defense materials?

A Coating adhesion testing evaluates the bonding strength between coatings and their underlying substrates, ensuring that these materials meet the highest standards of quality and performance.

Q Which industries benefit from our coating adhesion testing services?

A Our services cater to a range of industries, including aerospace, automotive, construction, and defense.

Q What methods do you employ for coating adhesion testing?

A We use various methods, including Tape Test (ASTM D3359), Pull-Off Test (DIN 53164), and Scotch Tape Adhesion Test.

Q How can I ensure compliance with industry regulations through your laboratory services?

A Our team will work closely with you to understand your specific needs and develop a testing plan that meets regulatory requirements.

Conclusion

In conclusion, coating adhesion testing is an essential component of material evaluation in the defense industry. At Eurolab, we offer comprehensive laboratory services for this critical aspect of material performance. By choosing our methods for coating adhesion testing in defense materials, you can ensure the durability and reliability of your products, meeting the highest standards of quality and performance.

We invite you to explore our range of services and learn how Eurolabs expertise can support your business needs.