Testing coating adhesion for military-grade polymers and composites

The Crucial Role of Testing Coating Adhesion for Military-Grade Polymers and Composites Ensuring Performance and Reliability in Critical Applications

In the realm of military-grade polymers and composites, where reliability and performance are paramount, testing coating adhesion assumes a critical importance. The right coating can make all the difference between mission success or failure, system malfunction, or even human life safety. At Eurolab, we specialize in providing this essential laboratory service to businesses operating within the defense sector, ensuring that their polymers and composites meet stringent performance requirements.

Why Testing Coating Adhesion is Essential for Military-Grade Polymers and Composites

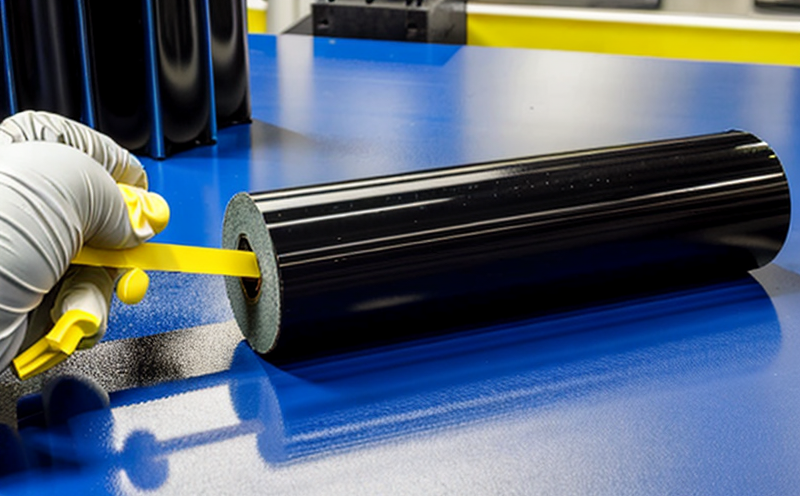

Testing coating adhesion involves evaluating the bond between a coating material and a polymer or composite substrate. This process is vital in military applications because coatings are used extensively to enhance the performance of various systems, including aircraft surfaces, tank armor, and equipment components. Coatings can provide corrosion resistance, improve durability, reduce weight, and enhance functionality.

The importance of testing coating adhesion cannot be overstated. Poorly bonded coatings can lead to catastrophic failures, compromising system integrity and potentially putting lives at risk. A well-executed coating adhesion test ensures that the chosen material adheres sufficiently to withstand various environmental stresses, including temperature fluctuations, exposure to chemicals or fuels, and mechanical loads.

Advantages of Testing Coating Adhesion for Military-Grade Polymers and Composites

Eurolabs laboratory service offers numerous benefits when it comes to testing coating adhesion for military-grade polymers and composites. Some of the key advantages include

Improved System Reliability By ensuring that coatings adhere correctly, manufacturers can increase system reliability, reduce maintenance costs, and enhance overall performance.

Enhanced Performance Properly bonded coatings can improve thermal management, corrosion resistance, and mechanical durability, making them ideal for demanding military environments.

Weight Reduction Coatings can significantly reduce the weight of various components, enhancing mobility and efficiency in critical applications.

Cost Savings By minimizing system failures and downtime, testing coating adhesion helps companies save money on repair and replacement costs.

Regulatory Compliance Our laboratory service ensures that products meet or exceed relevant military standards, reducing regulatory hurdles and ensuring compliance with industry requirements.

Key Benefits of Eurolabs Testing Coating Adhesion Service

At Eurolab, we pride ourselves on delivering high-quality results in an efficient and cost-effective manner. Some key benefits of our testing coating adhesion service include

Customized Solutions We work closely with clients to develop tailored test protocols that meet their specific requirements.

State-of-the-Art Equipment Our laboratory is equipped with the latest technology, ensuring accurate and reliable results.

Experienced Personnel Our team of experts has extensive knowledge in testing coating adhesion for military-grade polymers and composites.

Rapid Turnaround Times We strive to deliver test reports promptly, minimizing delays in project timelines.

Frequently Asked Questions (FAQs)

What types of coatings can be tested?

Our laboratory service supports the evaluation of various coating materials, including paints, primers, epoxies, and other polymers. We also accommodate testing for different substrate materials, such as carbon fiber reinforced polymers (CFRP), aluminum, and steel.

How are tests conducted at Eurolab?

We utilize a range of standardized test methods to assess coating adhesion, including ASTM D3359, ISO 4624, and DIN 53172- Our team of experts will work with clients to determine the most suitable test protocol for their specific needs.

What information do I need to provide for testing?

To initiate testing, please provide us with detailed specifications regarding your coating material, substrate type, and intended application. Additionally, share any relevant documentation or certifications that may influence the testing process.

How long does the testing process take?

Turnaround times vary depending on the scope of the project and the complexity of the test protocol. Typically, results are available within 1-5 business days after sample receipt.

Conclusion

In conclusion, testing coating adhesion for military-grade polymers and composites is a critical service that ensures performance reliability in high-stakes applications. At Eurolab, we specialize in providing this essential laboratory service to businesses operating within the defense sector. Our team of experts offers customized solutions, utilizing state-of-the-art equipment to deliver accurate results promptly.

By entrusting us with your testing needs, you can rest assured that your coatings adhere correctly, enhancing system reliability and performance while minimizing costs associated with system failures. Contact Eurolab today to learn more about our laboratory services and how we can support your businesss mission-critical requirements.