The Ultimate Assurance of Product Durability Shock and Impact Testing by Eurolab

In todays fast-paced world of manufacturing and innovation, businesses are constantly seeking ways to improve product quality, reliability, and longevity. One critical aspect of ensuring product durability is subjecting it to rigorous testing procedures that simulate real-world conditions. This is where shock and impact testing comes in a specialized laboratory service provided by Eurolab that helps manufacturers validate the integrity of their products under extreme forces.

What is Shock and Impact Testing?

Shock and impact testing is a type of dynamic testing that involves subjecting materials, components, or entire products to sudden, high-force impacts. These impacts can be in the form of drops, bumps, shocks, or other forms of mechanical stress. The primary goal of shock and impact testing is to assess a products ability to withstand such forces without sustaining damage or failing catastrophically.

In essence, shock and impact testing helps manufacturers understand how their products will perform under various scenarios, including those involving accidents, falls, or other unforeseen events. By simulating real-world conditions in a controlled laboratory environment, businesses can identify potential weaknesses and make necessary improvements to ensure product safety and reliability.

Why is Shock and Impact Testing Essential for Businesses?

In todays competitive market, manufacturers must prioritize product quality and durability above all else. Failure to do so can result in costly recalls, damage to brand reputation, and even financial ruin. By incorporating shock and impact testing into their development process, businesses can

Ensure product safety Identify potential hazards and eliminate them before they cause harm to users.

Improve product reliability Develop products that are less prone to failure, reducing the risk of costly repairs or replacements.

Enhance brand reputation Demonstrate a commitment to quality and customer satisfaction through rigorous testing procedures.

Comply with regulatory requirements Meet industry standards for product safety and performance.

Reduce liability Minimize the risk of lawsuits by demonstrating that products have been thoroughly tested for durability.

Advantages of Using Shock and Impact Testing

Eurolabs shock and impact testing services offer a range of benefits to manufacturers, including

Accurate predictions of real-world performance Simulate real-world conditions in a controlled laboratory environment.

Early detection of product weaknesses Identify potential issues before they cause harm or damage.

Compliance with industry standards Ensure that products meet regulatory requirements for safety and performance.

Reduced risk of product failure Develop products that are less prone to failure, reducing the risk of costly repairs or replacements.

Increased customer satisfaction Deliver high-quality products that meet user expectations.

QA Frequently Asked Questions about Shock and Impact Testing

What types of products require shock and impact testing?

Products subject to sudden impacts, such as vehicles, safety gear, and industrial equipment.

Components or materials with critical safety implications, like helmets, seatbelts, and airbags.

How is shock and impact testing performed?

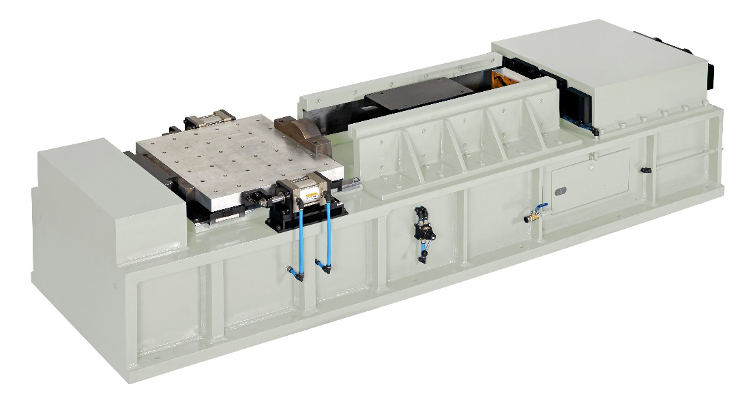

Testing is conducted in a controlled laboratory environment using specialized equipment, such as drop towers or impact hammers.

What are the typical forces involved in shock and impact testing?

Forces can range from 1-100 Gs (gees), depending on the specific requirements of the product being tested.

Can Eurolabs shock and impact testing services be customized to meet our business needs?

Yes, we offer tailored testing programs that cater to your unique product development requirements.

How long does a typical shock and impact testing program take?

Testing duration can vary depending on the complexity of the test and the type of equipment being used.

Conclusion Trust Eurolab for Your Shock and Impact Testing Needs

In todays fast-paced world of manufacturing, its essential to prioritize product quality and durability above all else. By incorporating shock and impact testing into your development process, you can ensure that your products meet regulatory requirements, customer expectations, and industry standards.

At Eurolab, our team of experts is dedicated to providing comprehensive shock and impact testing services that cater to the unique needs of each client. With state-of-the-art equipment and a commitment to delivering high-quality results, we are confident in our ability to help manufacturers like you develop products that are safe, reliable, and perform well under various conditions.

Contact Eurolab today to discuss your product development requirements and how our shock and impact testing services can help take your business to the next level.