Shock Resistance of Critical Components like Controllers and Motors

The Importance of Shock Resistance for Critical Components Ensuring Reliability in a Turbulent World

In todays fast-paced and increasingly complex technological landscape, the reliability of critical components is more crucial than ever. Whether its controlling machinery, powering electrical systems, or managing data transmission, these components are the backbone of modern industry. However, theyre not immune to the vicissitudes of life environmental factors like shock, vibration, and extreme temperatures can cause them to malfunction or fail catastrophically.

This is where Shock Resistance of Critical Components comes into play. By testing critical components like controllers and motors for their ability to withstand physical shocks, manufacturers can ensure they meet stringent performance standards and minimize downtime. At Eurolab, we offer a comprehensive laboratory service designed to subject these critical components to rigorous shock resistance tests.

In this article, well delve into the importance of Shock Resistance of Critical Components, highlighting its advantages and benefits for businesses. Well also address frequently asked questions and provide a detailed overview of our laboratory services.

What is Shock Resistance of Critical Components?

Shock Resistance of Critical Components refers to the ability of these components to withstand sudden, intense shocks or impacts without sustaining damage or malfunctioning. This can be particularly critical in industries where equipment downtime has significant financial implications, such as manufacturing, transportation, and healthcare.

When a component fails due to shock or vibration, it can lead to costly repairs, lost productivity, and compromised safety. In some cases, a single failure event can have far-reaching consequences, affecting entire supply chains and impacting customer satisfaction.

Advantages of Shock Resistance Testing

Eurolabs Shock Resistance of Critical Components laboratory service offers numerous benefits for businesses. Here are just a few

Improved Reliability By testing critical components for shock resistance, manufacturers can ensure they meet or exceed industry standards for reliability.

Reduced Downtime Regular shock testing enables proactive maintenance and repair, minimizing equipment downtime and associated costs.

Enhanced Safety By identifying potential weaknesses in critical components, businesses can reduce the risk of accidents and injuries caused by malfunctioning equipment.

Compliance with Industry Regulations Our laboratory services ensure that products meet or exceed regulatory requirements for shock resistance, reducing the risk of costly recalls or product holds.

Other key benefits include

Increased Efficiency By identifying potential failure points before they occur, businesses can optimize production schedules and reduce waste.

Competitive Advantage Demonstrating a commitment to quality and reliability through regular shock testing can be a powerful differentiator in the market.

Cost Savings Identifying and addressing potential weaknesses early on can save companies significant sums in repair costs, maintenance, and replacement.

How Does Shock Resistance Testing Work?

At Eurolab, our team of experienced engineers and technicians employ state-of-the-art equipment to subject critical components to rigorous shock testing protocols. Our laboratory services include

Impact Testing Simulating the effects of sudden impacts or drops on critical components.

Vibration Testing Subjecting components to controlled levels of vibration to assess their response.

Temperature Cycling Exposing components to extreme temperatures to evaluate their thermal stability.

Our tests are designed to simulate real-world scenarios, providing businesses with actionable insights into the shock resistance of their critical components. By partnering with Eurolab, manufacturers can ensure theyre producing products that meet or exceed industry standards for reliability and performance.

QA Frequently Asked Questions

Here are some common questions we receive about Shock Resistance of Critical Components

Q What types of critical components do you test?

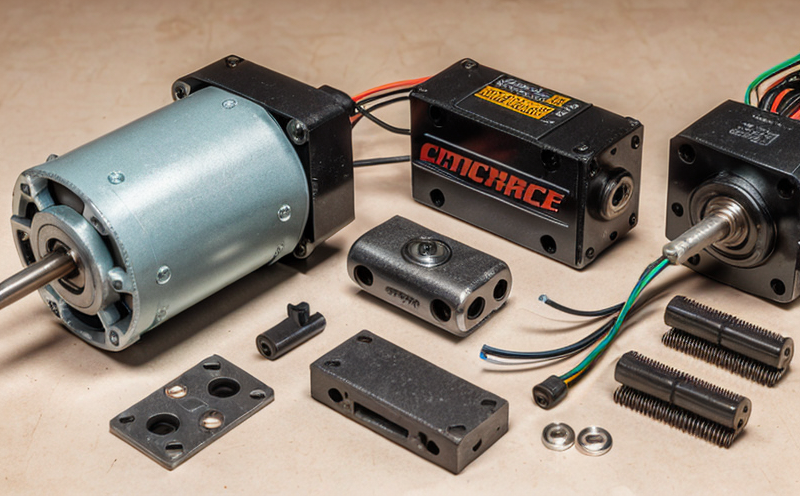

A We test a wide range of components, including controllers, motors, sensors, and actuators.

Q How do I know if my component needs shock resistance testing?

A Any critical component thats prone to vibration or impact should be tested for shock resistance. This typically includes components used in transportation, manufacturing, and heavy industry settings.

Q What are the benefits of shock testing over other forms of testing?

A Shock testing provides a more accurate representation of real-world conditions than other forms of testing, such as vibration or temperature cycling alone.

Conclusion

In todays fast-paced business environment, ensuring the reliability and performance of critical components is crucial. By partnering with Eurolab for Shock Resistance of Critical Components, manufacturers can

Improve product reliability

Reduce equipment downtime

Enhance safety standards

Meet industry regulatory requirements

Dont let shock or vibration-related failures compromise your businesss reputation or bottom line. Trust Eurolab to provide the comprehensive laboratory services you need to ensure the reliability and performance of your critical components.

About Eurolab

At Eurolab, were dedicated to providing cutting-edge laboratory services that help businesses like yours stay ahead of the competition. Our team of experienced engineers and technicians use state-of-the-art equipment to deliver precise, actionable insights into the shock resistance of critical components.

Whether you need comprehensive testing, maintenance support, or regulatory compliance assistance, our team is here to help. Contact us today to learn more about our laboratory services and how we can help your business thrive in a turbulent world.