Simulating Short Circuit Events in High-Power Devices

Simulating Short Circuit Events in High-Power Devices Unlocking Safety and Efficiency

In todays fast-paced world of technological advancements, high-power devices play a vital role in industries such as automotive, aerospace, renewable energy, and beyond. These cutting-edge components are designed to operate under extreme conditions, ensuring optimal performance while minimizing the risk of failure. However, unforeseen events can still occur, posing significant threats to safety, equipment reliability, and business continuity.

Thats where Simulating Short Circuit Events in High-Power Devices comes into play a laboratory service provided by Eurolab that simulates short circuit scenarios in high-power devices, enabling manufacturers and operators to predict, prevent, and mitigate potential failures. In this article, well delve into the importance of this simulation process, its advantages, and why its an essential tool for businesses relying on high-power devices.

What is Simulating Short Circuit Events in High-Power Devices?

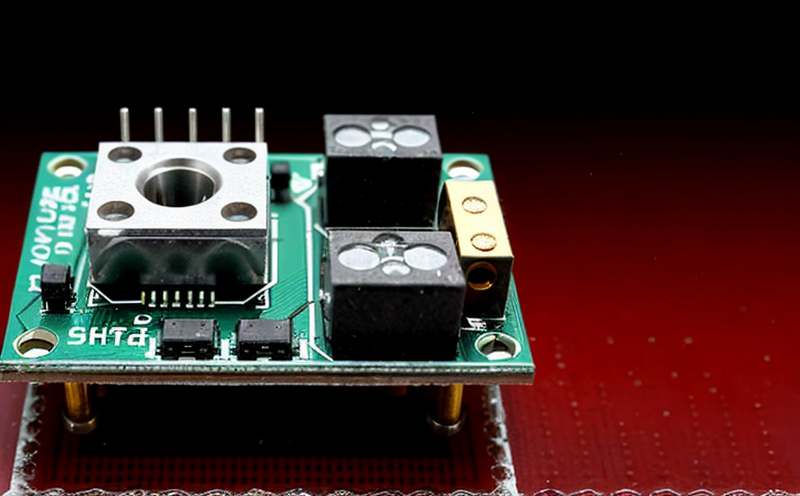

Simulating short circuit events involves replicating the conditions under which a device may experience an unintended flow of electrical current between two points. This can occur due to various reasons such as human error, design flaws, or equipment failure. Eurolabs expert team employs specialized laboratory equipment and techniques to simulate these scenarios, allowing for thorough analysis and assessment.

The Benefits of Simulating Short Circuit Events in High-Power Devices

Eurolabs simulation services offer numerous benefits, making it an indispensable tool for businesses relying on high-power devices

Predictive Maintenance By simulating short circuit events, manufacturers can identify potential failure points before they occur. This proactive approach enables scheduled maintenance, reducing downtime and increasing overall efficiency.

Design Improvements Simulated scenarios provide valuable insights into design vulnerabilities, enabling engineers to optimize component designs, enhance safety features, and improve overall performance.

Cost Savings Preventing equipment failures through simulation leads to significant cost savings in replacement parts, labor, and lost productivity. Additionally, reduced downtime ensures a steady revenue stream.

Enhanced Safety By understanding the potential risks associated with short circuit events, manufacturers can develop targeted safety protocols, reducing the likelihood of accidents and ensuring compliance with industry regulations.

Compliance and Regulatory Requirements Simulated scenarios help businesses meet regulatory standards and industry guidelines, such as those set by IEC or IEEE. This ensures that high-power devices are designed, manufactured, and operated in accordance with established best practices.

Increased Efficiency Simulation services enable the testing of multiple scenarios, allowing engineers to fine-tune designs and optimize performance without the need for expensive physical prototypes or extensive field testing.

Key Benefits of Eurolabs Simulation Services

Eurolabs simulation services are tailored to meet the unique needs of each client. Our team leverages cutting-edge technology and expertise to deliver

Customized Scenarios We work closely with clients to develop tailored simulations that accurately replicate real-world conditions, ensuring results relevant to their specific applications.

Comprehensive Analysis Our expert analysts provide in-depth analysis of simulated data, identifying areas for improvement and offering actionable recommendations for design optimization.

Cost-Effective Solution Simulation services offer a cost-effective alternative to physical testing, reducing the need for expensive equipment, labor, and resources.

Frequently Asked Questions (FAQs)

Q What types of high-power devices can be simulated?

A Eurolabs simulation services cater to a wide range of high-power devices, including but not limited to power electronics, motors, generators, transformers, and electrical cables.

Q How accurate are the simulated results?

A Our team employs state-of-the-art equipment and techniques to ensure accuracy. Simulated results are validated through rigorous testing and analysis, guaranteeing relevance to real-world conditions.

Q Can simulation services be tailored to specific industry requirements?

A Absolutely! Eurolabs expert team collaborates with clients to develop customized simulation scenarios that meet the unique needs of their industries, ensuring compliance with regulatory standards and best practices.

Q What is the typical turnaround time for simulated results?

A Turnaround times vary depending on the complexity of the project. However, our team typically delivers comprehensive analysis and actionable recommendations within a few weeks of completing the simulation process.

Conclusion

Simulating short circuit events in high-power devices is no longer a luxury but an essential service for businesses that rely on these critical components. Eurolabs expertise in this area enables manufacturers to predict, prevent, and mitigate potential failures, ensuring safety, efficiency, and compliance with industry regulations.

By partnering with Eurolab, clients can unlock the full potential of their high-power devices while minimizing risks and maximizing returns. Whether youre an automotive manufacturer or a renewable energy developer, our simulation services will provide you with actionable insights to drive innovation and success in your industry.