Testing the Durability of Components After Short Circuit Exposure

The Critical Role of Testing the Durability of Components After Short Circuit Exposure Ensuring Product Reliability and Safety

In todays fast-paced world of electrical engineering and manufacturing, ensuring the reliability and safety of electronic components is paramount. One critical aspect of this endeavor is testing the durability of components after short circuit exposure. This laboratory service, provided by Eurolab, is an essential tool for businesses seeking to validate their products performance under extreme conditions.

What is Testing the Durability of Components After Short Circuit Exposure?

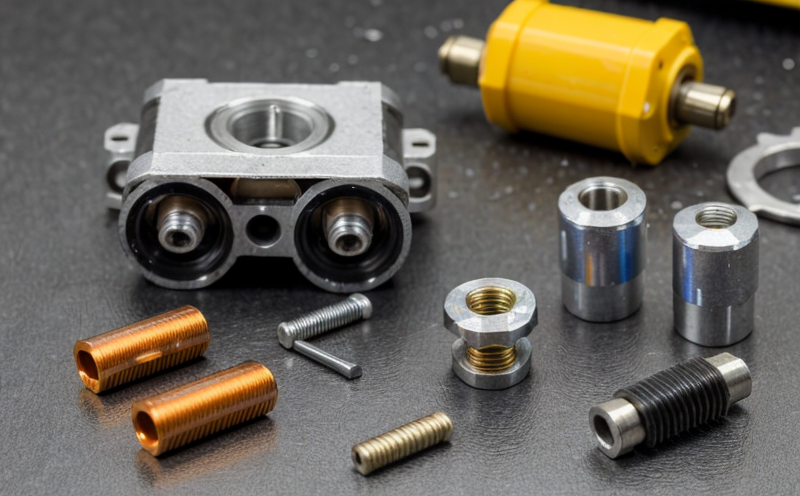

Testing the durability of components after short circuit exposure involves subjecting electronic components to a controlled short circuit condition and then assessing their ability to withstand the resulting stresses. This includes evaluating factors such as thermal resistance, electrical conductivity, and mechanical integrity. By simulating real-world scenarios where components may be exposed to short circuits, Eurolabs experts can provide valuable insights into a products reliability and safety.

Why is Testing the Durability of Components After Short Circuit Exposure Essential for Businesses?

The consequences of inadequate component testing can be severe, leading to costly failures, recalls, and even safety hazards. By incorporating testing for durability after short circuit exposure into their quality control protocols, businesses can

Ensure product reliability Confidence in a products ability to withstand extreme conditions is crucial for meeting customer expectations and maintaining market share.

Mitigate risks and liabilities Companies that test for durability after short circuit exposure demonstrate a commitment to safety and responsibility, reducing the risk of costly lawsuits and reputational damage.

Comply with regulatory requirements Many industries, such as aerospace and automotive, have strict regulations governing component testing. Eurolabs services help companies meet these standards.

Reduce warranty claims and returns By identifying potential issues early on, businesses can minimize costs associated with warranties, returns, and repairs.

Key Benefits of Testing the Durability of Components After Short Circuit Exposure

Eurolabs comprehensive laboratory service offers numerous benefits to businesses seeking to optimize their component testing

Early defect detection Identify potential issues before they become costly problems.

Reduced warranty claims Minimize costs associated with warranties and returns by identifying defects early on.

Improved product design Use test data to inform design decisions, leading to more reliable products.

Enhanced customer confidence Demonstrate a commitment to safety and quality through rigorous testing protocols.

How Does Eurolabs Testing the Durability of Components After Short Circuit Exposure Work?

Eurolabs expert technicians employ state-of-the-art equipment and precise methodologies to simulate real-world short circuit conditions. This includes

Controlled environment Test components in a controlled, climate-controlled setting to ensure accurate results.

Sophisticated testing equipment Utilize the latest technology to subject components to various stressors, including thermal, electrical, and mechanical loads.

Expert analysis Experienced engineers provide detailed reports on test results, highlighting areas for improvement.

Frequently Asked Questions (FAQs)

Q What types of components can be tested through Eurolabs Testing the Durability of Components After Short Circuit Exposure service?

A Our laboratory can accommodate a wide range of electronic components, including but not limited to, capacitors, inductors, resistors, and ICs.

Q How long does the testing process typically take?

A The duration of testing varies depending on the complexity of the test protocol and the number of samples being tested. Our team works efficiently to ensure timely results without compromising accuracy.

Q Can Eurolabs Testing the Durability of Components After Short Circuit Exposure service be integrated into our existing quality control protocols?

A Absolutely! Our expert technicians are experienced in adapting to various testing protocols and can seamlessly integrate our services with your existing processes.

Conclusion

In conclusion, testing the durability of components after short circuit exposure is a critical aspect of ensuring product reliability and safety. By partnering with Eurolab, businesses can rest assured that their products meet the highest standards of quality and performance. Dont risk costly failures or reputational damage choose Eurolab for comprehensive laboratory services tailored to your needs.

Learn More About Eurolabs Testing Services

Visit our website to explore more about our testing services and discover how we can help you achieve excellence in product reliability and safety.